Selective hydrogenation method of crude isopentene

A crude isopentene, selective technology, applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbon purification/separation, etc., can solve the problem of 1-pentene content reduction, no separation and utilization, 1-pentene energy High consumption and other problems, to achieve the effect of increasing 1-pentene content, inhibiting isomerization reaction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0018] The hydrogenation reaction is carried out in a stainless steel tubular reactor, which is a stainless steel tubular reactor with a size of φ25mm×1000mm. The reaction tube is filled with 100ml catalyst, the catalyst is spherical Pd / Al 2 O 3 The supported catalyst has a particle size of 3 to 5 mm, the weight percentage of Pd in the catalyst is 0.25 to 0.32%, and the bottom of the reactor is filled with inert ceramic balls. The fresh catalyst needs to be activated with hydrogen before feeding. .

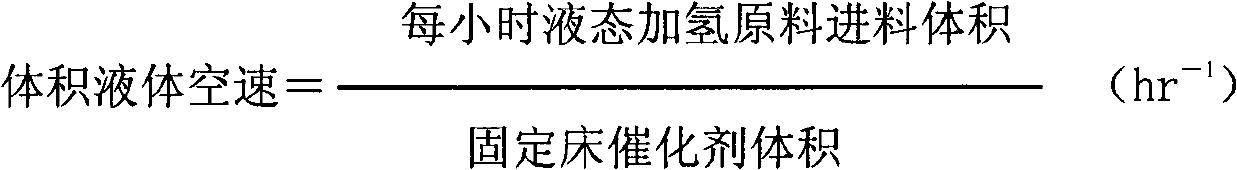

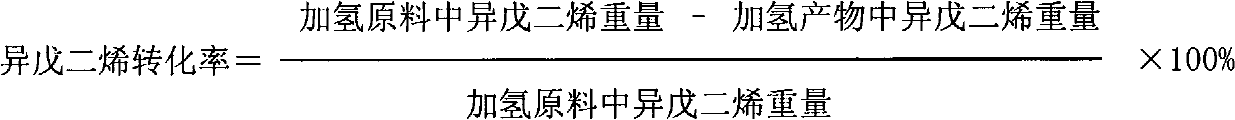

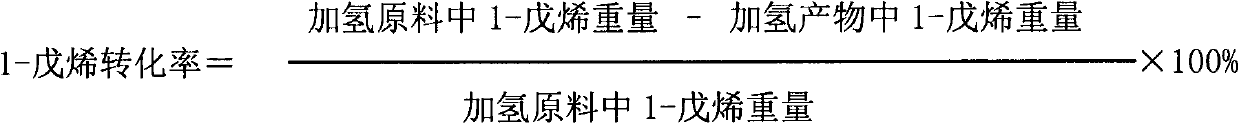

[0019] After preheating, the crude isopentene fraction is fed into the hydrogenation reactor from the bottom by a pump at a set rate. The mixed gas of CO and hydrogen enters the reactor through the gas distributor. After mixing, the hydrogen enters the catalyst bed for hydrogenation reaction. The hydrogenation product enters a gas-liquid separator from the upper part of the hydrogenation reactor, and the liquid phase material enters the product storage tank. The unreacted hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com