Method for preparing cyclohexyl acetate and method for preparing cyclohexanol ethanol

A technology of cyclohexyl acetate and acetic acid, applied in the preparation of carboxylate, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as no information disclosure, and achieve the effect of high selectivity of cyclohexyl acetate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] 500mL of macroporous strongly acidic hydrogen-type ion exchange resin (synthesized in the laboratory according to the classic literature method, suspension copolymerization of styrene solution containing 15% divinylbenzene to make white balls, and then sulfonated with concentrated sulfuric acid, measured Its exchange capacity is 5.2mmolH + / g dry basis) into the middle of the pre-reactor, and a certain amount of quartz sand is filled at both ends. In addition, the high-temperature-resistant sulfonic acid ion exchange resin (the brand is Amberlyst45, produced by Rhom&Hass Company) was crushed into a powder with a particle size of less than 200 mesh (0.074mm) with a multi-stage high-speed pulverizer, and pore-forming agents, lubricants, and antioxidants were added. The agent and adhesive are mixed evenly on a high-speed mixer, and then internally kneaded on an internal mixer at 180°C for 10 minutes to make the material completely plasticized, and then injected into a mold...

Embodiment 2

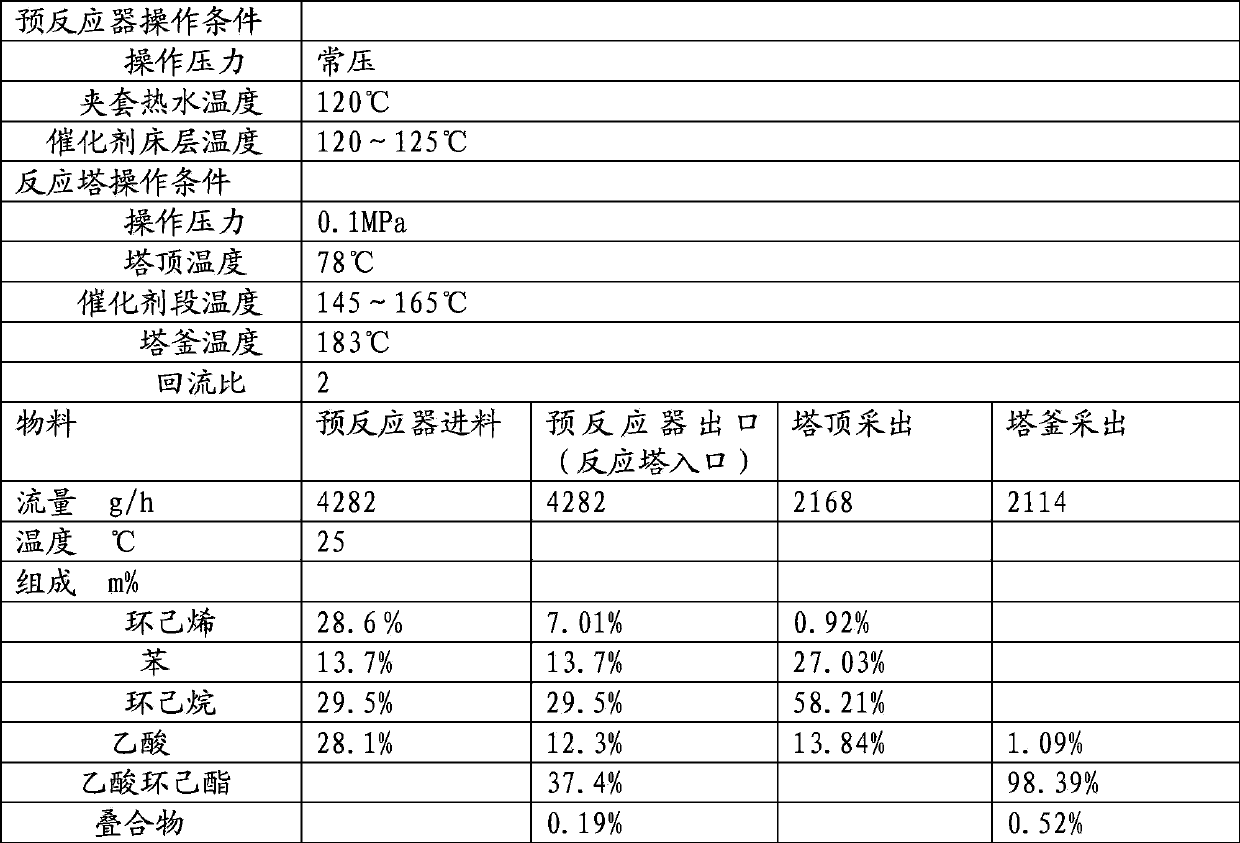

[0087] The configuration of reaction tower and catalyst is identical with embodiment 1. Only cyclohexene, cyclohexane and benzene mixture were used instead of cyclohexene for testing, and the pressure of the pre-reactor was 2.0MPa, and the reaction tower was operated under normal pressure. Adjust the heating capacity of the tower kettle and the top reflux flow to continuously react, and the reaction conditions and reaction results of the stable operating conditions are shown in Table 2 below.

Embodiment 3

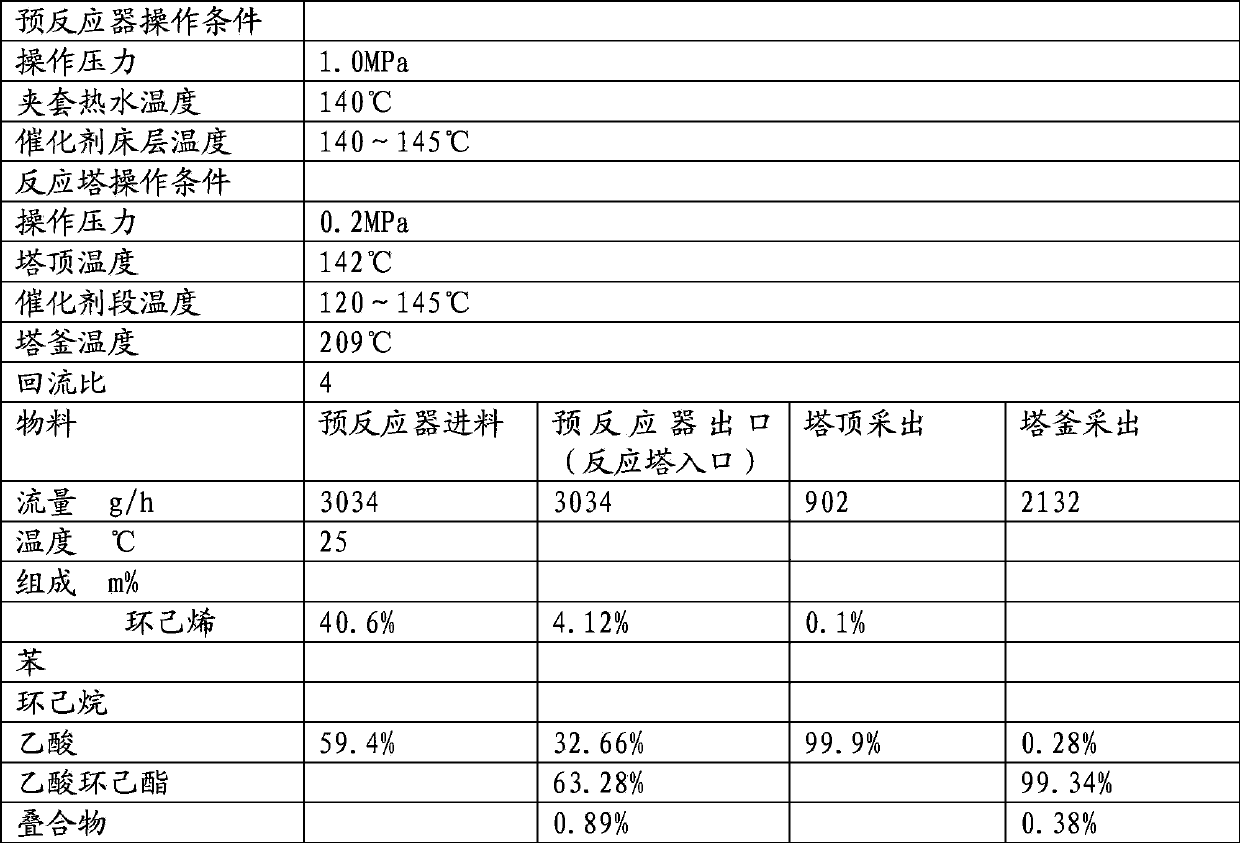

[0089] Put 500mL φ3~4 spherical H 0.5 Cs 2.5 PW 12 o 40 / SiO 2 The catalyst is loaded in the middle of the pre-reactor, and a certain amount of quartz sand is filled at both ends. In addition, the ball type H of φ3~4 0.5 Cs 2.5 PW 12 o 40 / S 2 Catalyst (by H 0.5 Cs 2.5 PW 12 o 40 Powder and coarse-pore silica gel powder with a particle size of less than 200 meshes are fully mixed in a mixer, rolled into a ball in a sugar coating machine with silica sol as a bonding machine, and then dried and roasted) sandwiched into a titanium mesh wave In the plate, a cylindrical structured packing with a diameter of 50 mm and a height of 50 mm was made. Put this packing type catalyst L into the middle part of the model reaction tower (1m high, equivalent to 12 theoretical trays), and put 1950mL glass spring packing with a diameter of 4mm and a height of 4mm at the top and bottom (the filling height is 1m, equivalent to 12 theoretical plates). 15 theoretical plates). The cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com