Method for recovering nuclear matrix protein (NMP) solvent in production of lithium ion battery

A technology of lithium ion battery and recovery method, applied in the field of secondary recovery and recycling of lithium battery auxiliary raw materials, can solve problems such as low recovery rate, large power consumption, environmental pollution, etc. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

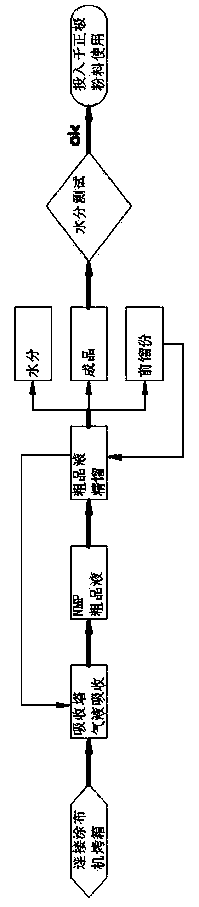

[0012] Such as figure 1 The illustrated invention includes the following processing steps:

[0013] (1) Use a spray absorption tower to absorb NMP mixed gas to prepare a high-concentration NMP mixed liquid: the absorption tower pumps out the high-concentration NMP mixed gas in the oven of the coating machine and transports it to the spray tower to make NMP The mixed gas spray tower and the deionized water in the spray tower carry out gas-liquid contact absorption, so that the gas NMP is dissolved into the deionized water to become a NMP mixed solution, and most of the NMP contained in the gas is removed with the repeated cycle of the mixed solution. Absorption, when the NMP concentration reaches the range of 60% to 80%, part of the high-concentration NMP solution, that is, NMP crude product liquid, is transported to the crude product tank;

[0014] (2) Vacuum rectification of NMP crude product liquid: transport the high-concentration NMP solution in the crude product tank to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com