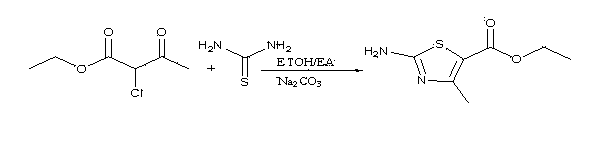

Preparation method of ethyl 2-amino-4-methylthiazole-5-carboxylate

A technology of methylthiazole and ethyl formate is applied in the field of preparation of 5-thiazole amide pharmaceutical intermediates, which can solve the problems of high energy consumption, high reaction temperature, long reaction time and the like, and achieves lowering reaction temperature and shortening reaction time. time, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 200ml of ethanol containing 25% ethyl acetate to the four-necked bottle, add 30.4g of thiourea, 1.5g of sodium carbonate, raise the temperature to 45°C, add 33g of ethyl 2-chloroacetoacetate dropwise, drop it in 20-30 minutes, and drop it Raise the temperature to 65°C and keep it warm for 5h, evaporate most of the solvent at normal pressure and cool to room temperature. Filter to remove unreacted thiourea, add the filtrate to 500ml of water, stir with 30% liquid caustic soda to adjust the pH to 9-10, stir for 0.5h, vacuum dry for 2h after suction filtration to obtain 36.7g of the product, the yield is 98.39%, mp: 172~173℃.

Embodiment 2

[0033] Add 200ml of ethanol containing 20% ethyl acetate to the four-necked bottle, add 30.4g of thiourea, 0.5g of sodium carbonate, raise the temperature to 45°C, add 33g of ethyl 2-chloroacetoacetate dropwise, drop it in 20-30min, drop it off Raise the temperature to 70°C and keep it warm for 5h, steam off most of the solvent under normal pressure and cool to room temperature. Remove unreacted thiourea by filtration, add the filtrate to 500ml of water, stir and adjust the pH to 9-10 with 30% liquid alkali, stir for 0.5h, vacuum dry for 2h after suction filtration to obtain 36.6g of the product, yield 98.12%, mp: 172~173℃.

Embodiment 3

[0035] Add 200ml of ethanol containing 10% ethyl acetate to the four-necked bottle, add 30.4g of thiourea, 0.5g of sodium carbonate, raise the temperature to 45°C, add 33g of ethyl 2-chloroacetoacetate dropwise, drop it in 20-30min, drop it off Raise the temperature to 65°C and keep it warm for 5h, evaporate most of the solvent at normal pressure and cool to room temperature. Remove unreacted thiourea by filtration, add the filtrate to 500ml of water, stir and adjust the pH to 9-10 with 30% liquid alkali, stir for 0.5h, vacuum dry for 2h after suction filtration to obtain 36.6g of the product, yield 98.12%, mp: 172~173℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com