Yellowing-resistant PC/ABS (polycarbonate-acrylonitrile-butadiene-styrene) alloy for automobile interior ornaments and preparation method thereof

A technology for automobile interior parts and yellowing resistance, which is applied in the field of yellowing-resistant PC/ABS alloy for automobile interior parts and its preparation, can solve the problems of poor yellowing resistance, complicated reasons, easy yellowing and the like, Achieve the effects of excellent yellowing resistance, simple preparation process and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Each component was weighed according to the corresponding Example 1 data in Table 1. The titanium dioxide used in Table 1 is titanium dioxide R902.

[0039] Put each component into a high-speed mixer, control the rotation speed at 300-400 rpm at room temperature, mix for 5-10 minutes, take it out and transfer it to a screw extruder, and extrude at a temperature of 240-260°C for granulation , to obtain the anti-yellowing PC / ABS alloy for the automotive interior parts.

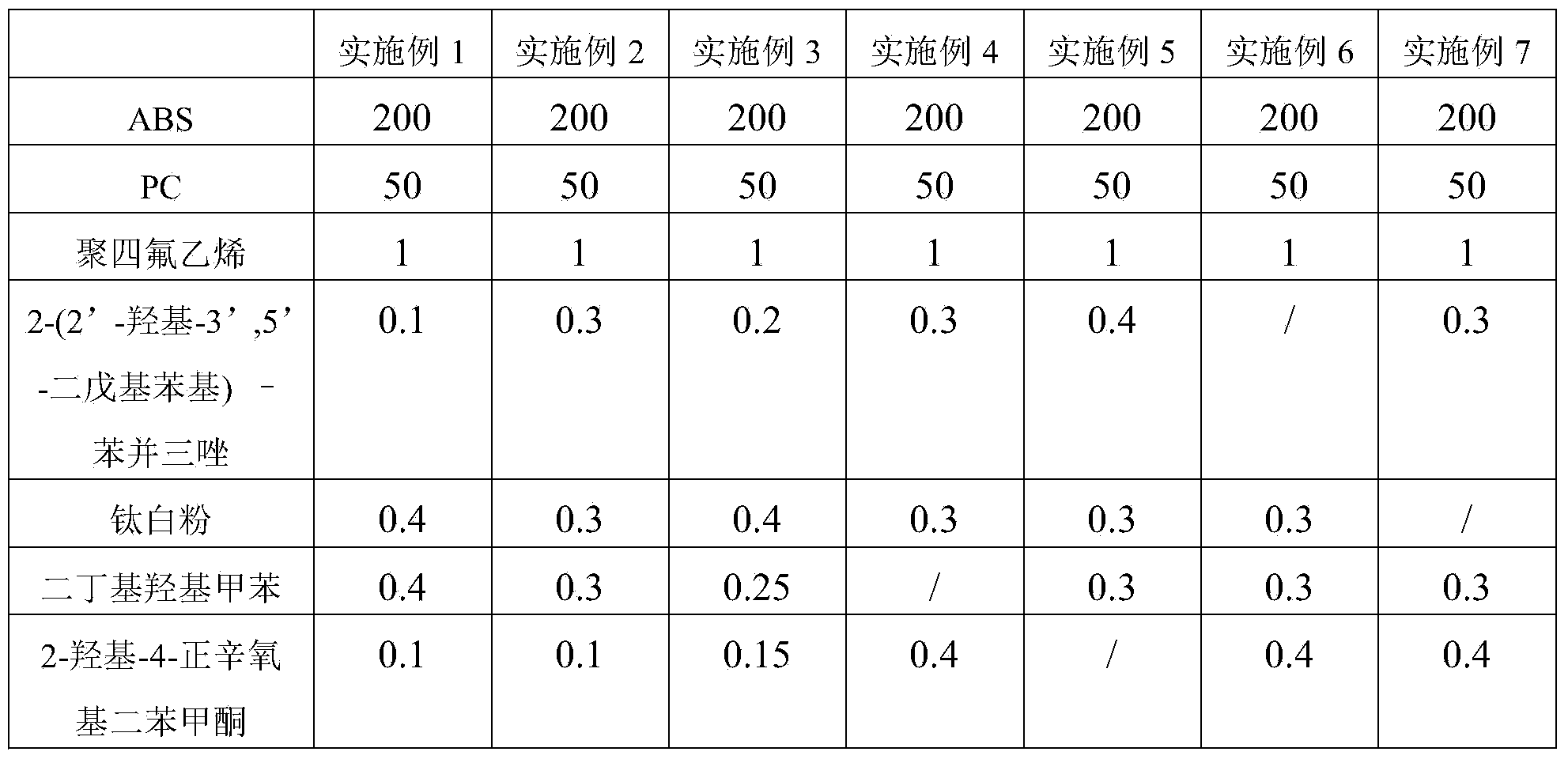

[0040] Table 1: Anti-yellowing PC / ABS alloy formula table for automotive interior parts Unit: kg

[0041]

Embodiment 2

[0043] Each component was weighed according to the corresponding data in Example 2 in Table 1, and the method described in Example 1 was adopted to obtain the anti-yellowing PC / ABS alloy for automotive interior parts.

Embodiment 3

[0045] Each component was weighed according to the corresponding data in Example 3 in Table 1, and the method described in Example 1 was adopted to obtain the anti-yellowing PC / ABS alloy for automotive interior parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com