Preparation method and application of immobilized aspergillus terreus lipase

A technology of lipase and Aspergillus terreus, which is applied in the field of preparation of immobilized Aspergillus terreus lipase, can solve the problems of poor stability, non-recyclability and low yield of Aspergillus terreus lipase, achieve good stereoselectivity and increase yield , good catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of immobilized Aspergillus terreus lipase comprises the following steps: reacting glycine protected by tert-butoxycarbonyl with mPEG2000 to obtain mPEG2000 modified by Boc-protected glycine; removing the Boc protecting group to obtain mPEG2000 modified by terminal amino group; Amino-modified mPEG2000 was reacted with sodium alginate to obtain Alg-g-mPEG; after Aspergillus terreus lipase was mixed with Alg-g-mPEG, it was reacted with α-CD to obtain Alg-g-PEG / α-CD.

[0035] As a preferred version of the present invention, the specific operation steps of the preparation method of the above-mentioned immobilized Aspergillus terreus lipase include:

[0036] a. Dissolve mPEG2000 in dry CH 2 Cl 2 Add Boc-protected glycine and DMAP, cool at -1-2°C for 10-15 minutes, then add DCC, react at -1-2°C for 18-24 hours, and the filtered solid is Boc-protected glycine-modified mPEG2000; The molar ratio of mPEG2000, Boc-protected glycine, DMAP, and DCC is 1:1.4~3...

Embodiment 1

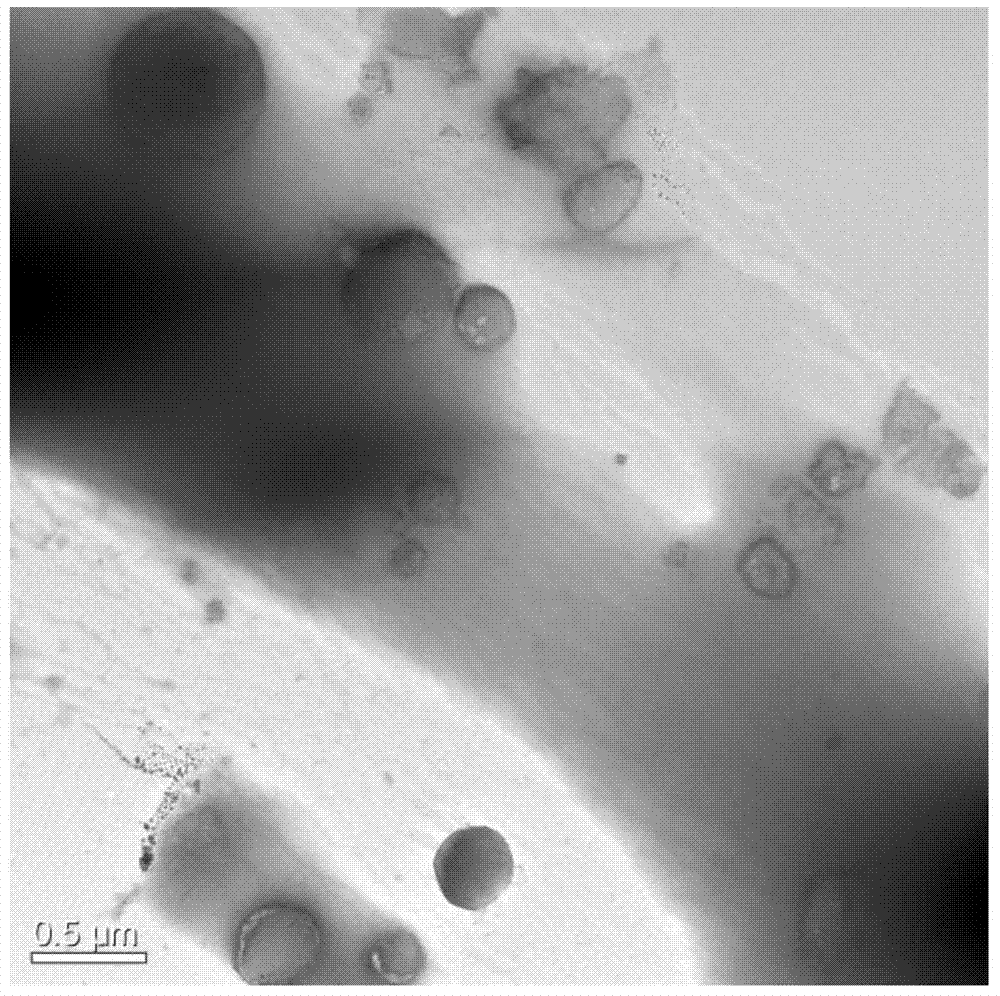

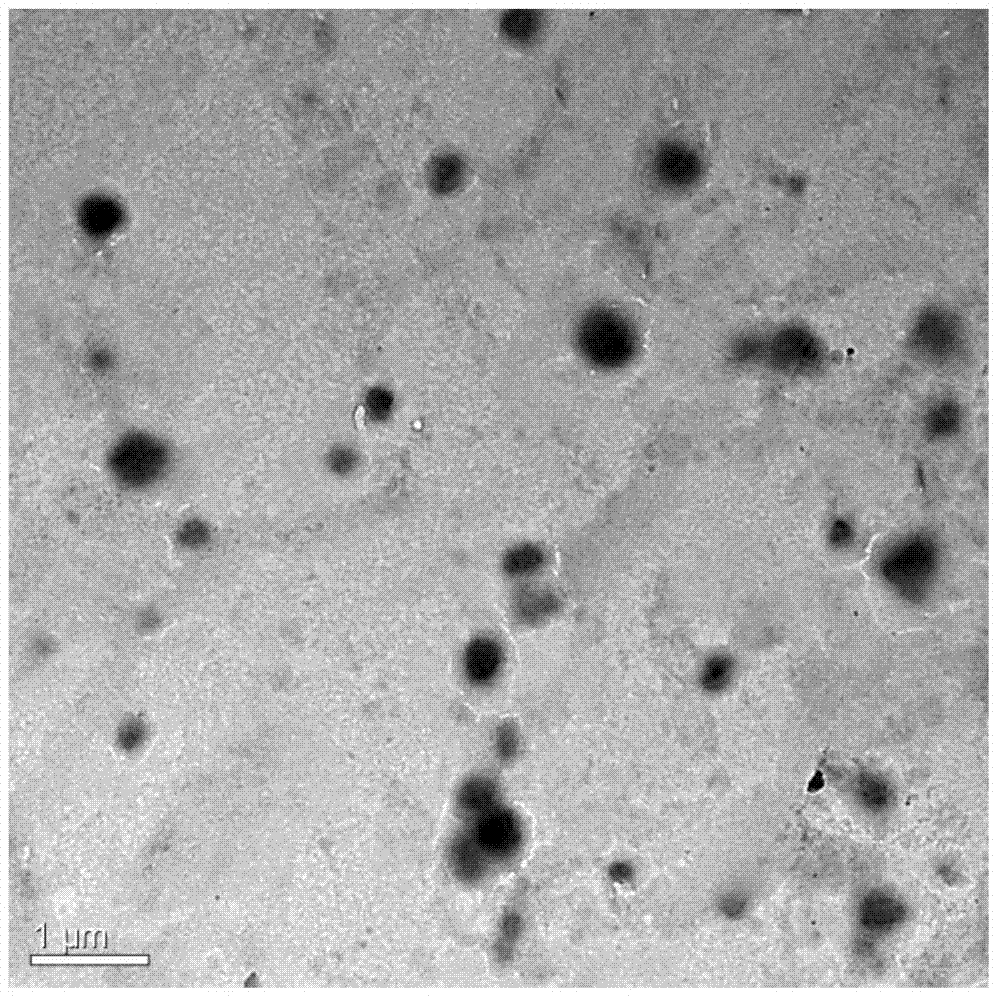

[0075] The preparation of embodiment 1 immobilized Aspergillus terreus lipase

[0076] Add 100 μL of Aspergillus terreus lipase enzyme solution to 2 mL of Alg-g-mPEG solution (pH=7.2, Tris-HCl) with a concentration of 1% (w / v), mix well, and slowly add dropwise to 4 mL with a concentration of 6% α-CD solution, after the dropwise addition, stirred at 4°C for 12 hours, the solution became turbid and a large amount of white precipitate was formed, the mixture was centrifuged, washed three times with Tris-HCl buffer solution with pH=7.2, and the precipitate was frozen Dry to obtain immobilized Aspergillus terreus lipase.

[0077] Add 1mL of tributyrin and 3mL of 0.1M sodium phosphate buffer solution with pH=7.0 into the flask, preheat in a water bath at 30°C for 10min, add 50mg of immobilized Aspergillus terreus lipase, react for 15min, then add 8mL of toluene, vortex Mix for 2 minutes, take the supernatant and centrifuge (2000rpm, 5min), take 4mL of the supernatant into a centri...

Embodiment 2

[0078] The preparation of embodiment 2 immobilized Aspergillus terreus lipase

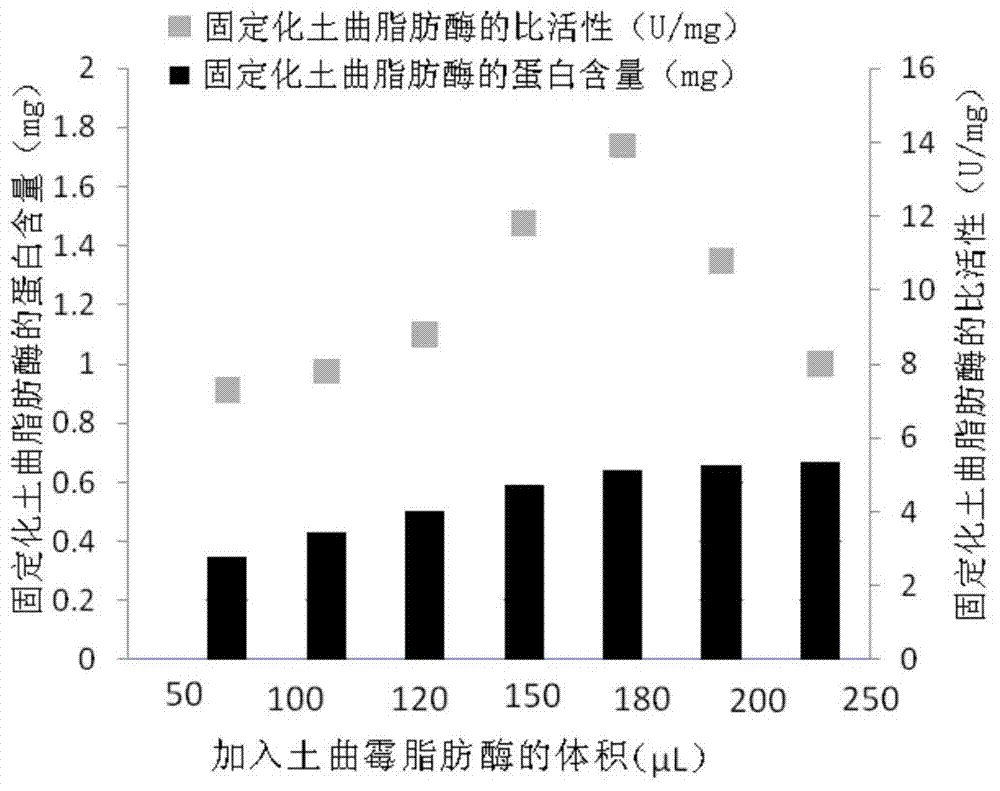

[0079] Add 180 μL of Aspergillus terreus lipase enzyme solution to 2 mL of Alg-g-mPEG solution (pH=7.4, Tris-HCl) with a concentration of 2% (w / v) and mix evenly, and slowly add it dropwise to 4 mL with a concentration of 9% α-CD solution, after the dropwise addition, stirred at 4°C for 24 hours, the solution became turbid and a large amount of white precipitate was formed, the mixture was centrifuged, washed three times with Tris-HCl buffer solution with pH=7.4, and the precipitate was frozen Dry to obtain immobilized Aspergillus terreus lipase.

[0080] Add 1mL of tributyrin and 3mL of 0.1M sodium phosphate buffer solution with pH=7.0 into the flask, preheat in a water bath at 30°C for 10min, add 50mg of immobilized Aspergillus terreus lipase, react for 15min, then add 8mL of toluene, vortex Mix for 2 minutes, take the supernatant and centrifuge (2000rpm, 5min), take 4mL of the supernatant into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com