Preparation method and application of immobilized Aspergillus terreus lipase

A technology for lipase and Aspergillus terreus, which is applied in the field of preparation of immobilized Aspergillus terreus lipase, can solve the problems of poor stability of Aspergillus terreus lipase, cannot be recycled, low yield and the like, and achieves good stereoselectivity and improved yield , the effect of good catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of immobilized Aspergillus terreus lipase comprises the following steps: reacting glycine protected by tert-butoxycarbonyl with mPEG2000 to obtain mPEG2000 modified by Boc-protected glycine; removing the Boc protecting group to obtain mPEG2000 modified by terminal amino group; Amino-modified mPEG2000 was reacted with sodium alginate to obtain Alg-g-mPEG; after Aspergillus terreus lipase was mixed with Alg-g-mPEG, it was reacted with α-CD to obtain Alg-g-PEG / α-CD.

[0035] As a preferred version of the present invention, the specific operation steps of the preparation method of the above-mentioned immobilized Aspergillus terreus lipase include:

[0036] a. Dissolve mPEG2000 in dry CH 2 Cl 2 Add Boc-protected glycine and DMAP, cool at -1-2°C for 10-15 minutes, then add DCC, react at -1-2°C for 18-24 hours, and the filtered solid is Boc-protected glycine-modified mPEG2000; The molar ratio of mPEG2000, Boc-protected glycine, DMAP, and DCC is 1:1.4~3...

Embodiment 1

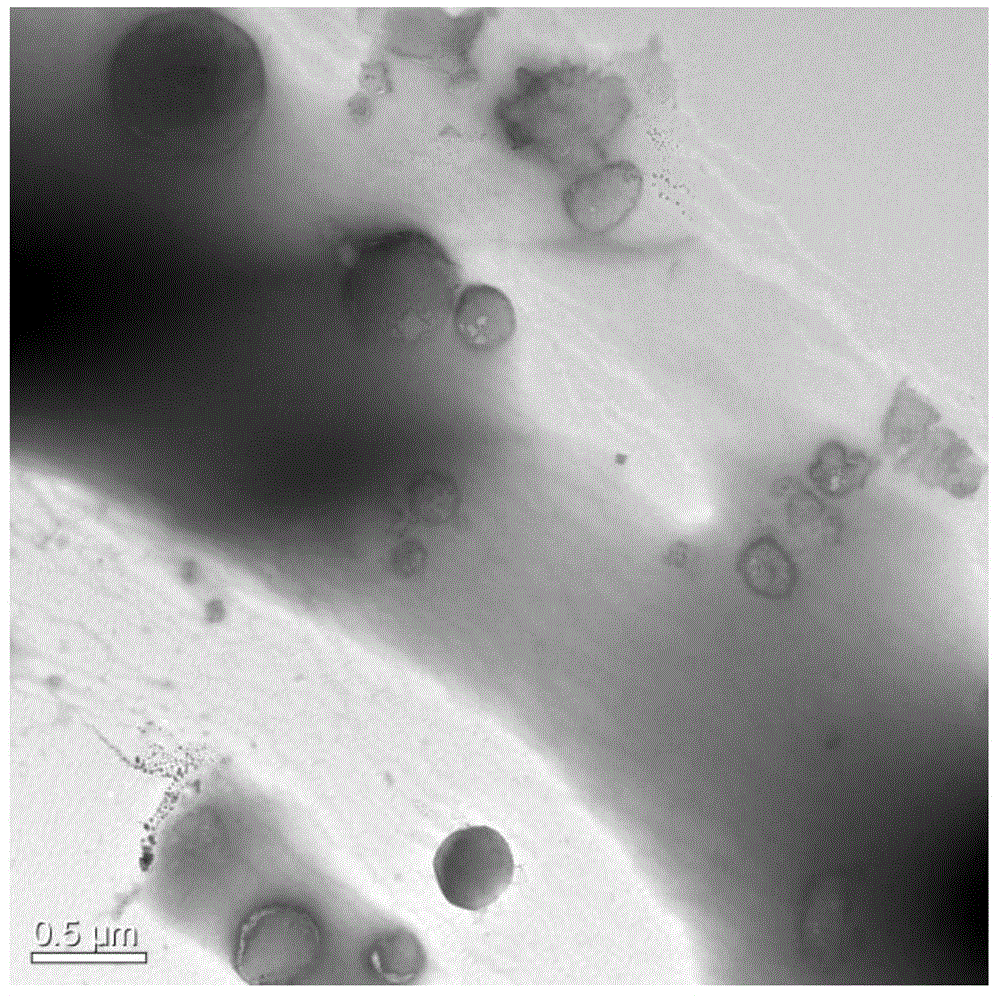

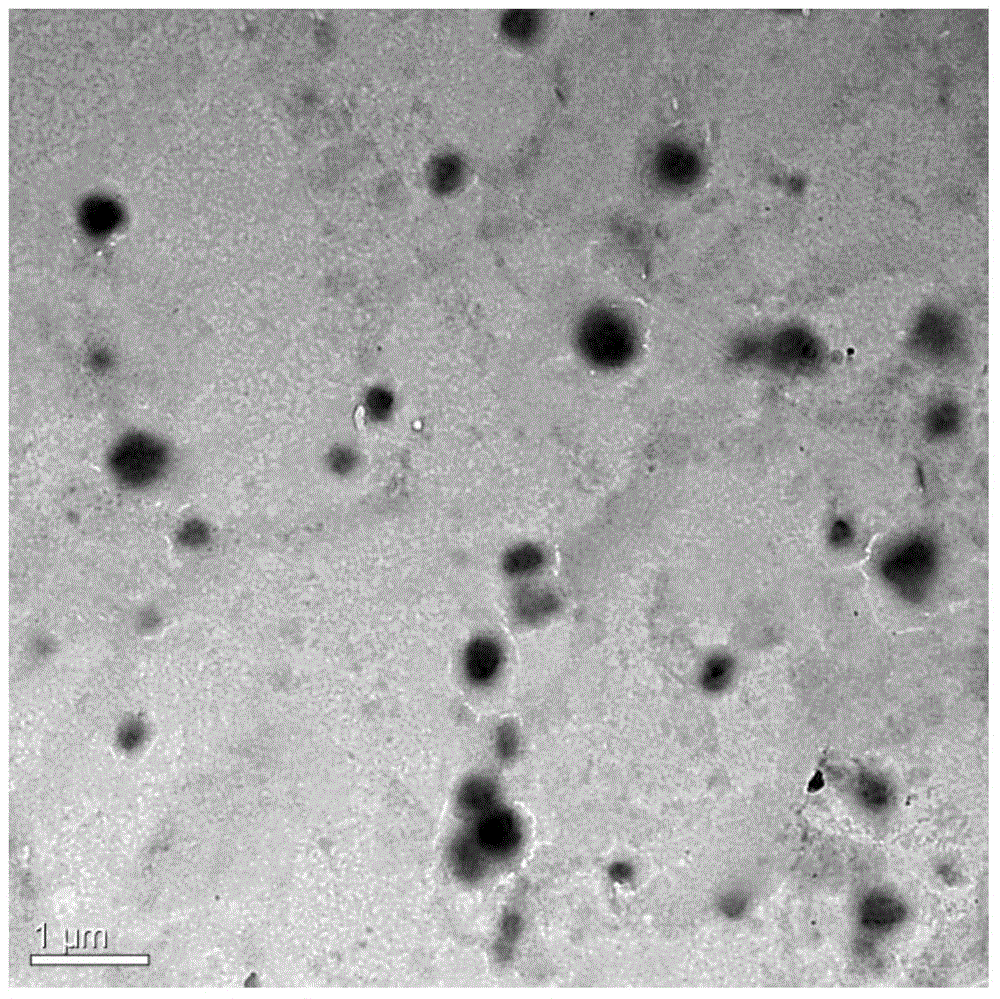

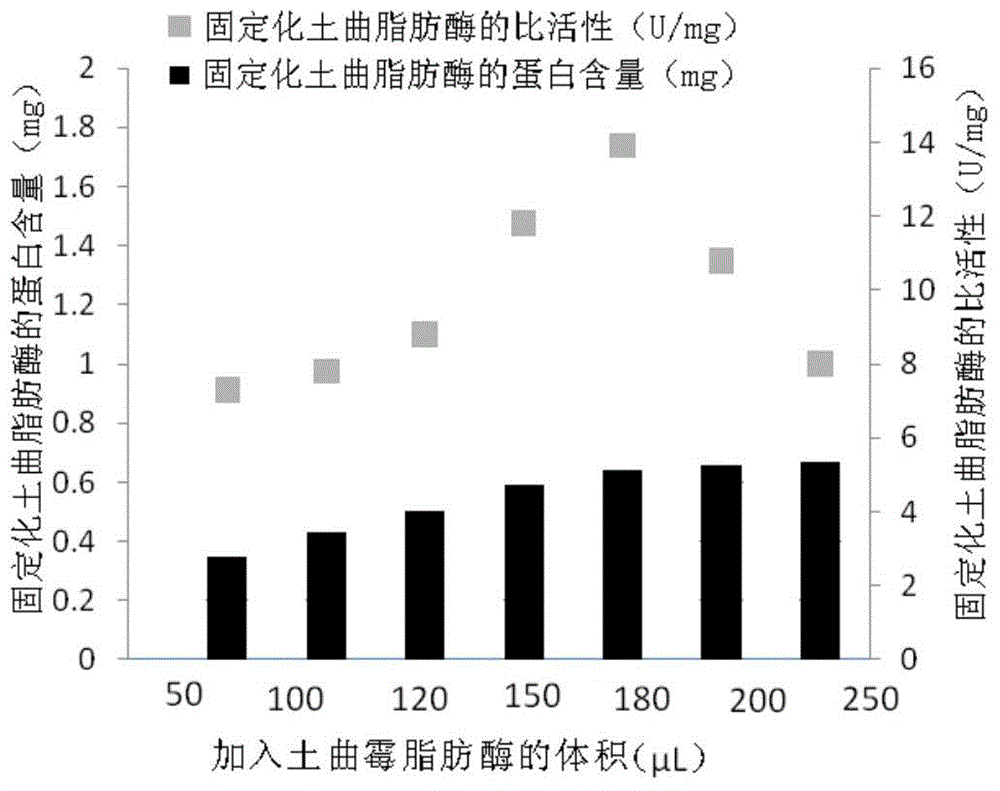

[0075] The preparation of embodiment 1 immobilized Aspergillus terreus lipase

[0076] Add 100 μL of Aspergillus terreus lipase enzyme solution to 2 mL of Alg-g-mPEG solution (pH=7.2, Tris-HCl) with a concentration of 1% (w / v), mix well, and slowly add dropwise to 4 mL with a concentration of 6% α-CD solution, after the dropwise addition, stirred at 4°C for 12 hours, the solution became turbid and a large amount of white precipitate was formed, the mixture was centrifuged, washed three times with Tris-HCl buffer solution with pH=7.2, and the precipitate was frozen Dry to obtain immobilized Aspergillus terreus lipase.

[0077] Add 1mL of tributyrin and 3mL of 0.1M sodium phosphate buffer solution with pH=7.0 into the flask, preheat in a water bath at 30°C for 10min, add 50mg of immobilized Aspergillus terreus lipase, react for 15min, then add 8mL of toluene, vortex Mix for 2 minutes, take the supernatant and centrifuge (2000rpm, 5min), take 4mL of the supernatant into a centri...

Embodiment 2

[0078] The preparation of embodiment 2 immobilized Aspergillus terreus lipase

[0079] Add 180 μL of Aspergillus terreus lipase enzyme solution to 2 mL of Alg-g-mPEG solution (pH=7.4, Tris-HCl) with a concentration of 2% (w / v) and mix evenly, and slowly add it dropwise to 4 mL with a concentration of 9% α-CD solution, after the dropwise addition, stirred at 4°C for 24 hours, the solution became turbid and a large amount of white precipitate was formed, the mixture was centrifuged, washed three times with Tris-HCl buffer solution with pH=7.4, and the precipitate was frozen Dry to obtain immobilized Aspergillus terreus lipase.

[0080] Add 1mL of tributyrin and 3mL of 0.1M sodium phosphate buffer solution with pH=7.0 into the flask, preheat in a water bath at 30°C for 10min, add 50mg of immobilized Aspergillus terreus lipase, react for 15min, then add 8mL of toluene, vortex Mix for 2 minutes, take the supernatant and centrifuge (2000rpm, 5min), take 4mL of the supernatant into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com