Method for nondegradable gel breaking of vegetable gelatin fracturing fluid

A fracturing fluid, non-degradable technology, used in chemical instruments and methods, earthwork drilling, drilling composition, etc. It can reduce the construction process and quality control points, achieve good economic benefits and environmental protection effects, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

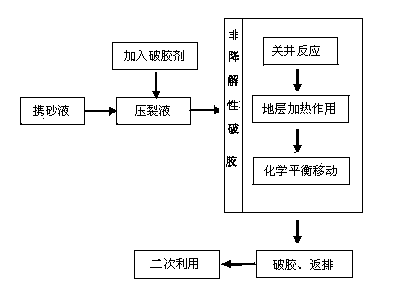

[0031] Such as figure 1 As shown, a method for non-degradable gel breaking of vegetable gum fracturing fluid is characterized in that: the method comprises the steps:

[0032] 1) Preparation of fracturing fluid: Weigh 0.28g of vegetable gum thickener, stir at 2000rad / min, slowly and evenly add it to 100mL of tap water, stir for 3-5mim and stop, let stand for 1-2h, Make it fully swell; add 0.3mL clay stabilizer NTWDJ-1, 0.1mL fungicide SSJ-1, stir for 30-90s; add 0.4mL drainage aid CF-5D, stir for 30-90s; add 0.015mL compound Gel breaker FPJJ-1, stir for 60-90s, add 0.25mL of cross-linking agent JLJ-1, stir for 60-90s, and that’s it.

[0033] 2) Non-degradable gel breaking: refers to the reaction of the composite gel breaker FPJJ-1 in the fracturing fluid in step 1 with other additives in the formulation during the well shut-in process after fracturing; At a temperature of 80°C, the composite gel breaker FPJJ-1 continuously releases hydrogen ions, which reduces the borate dis...

Embodiment 2

[0038] It is basically the same as Example 1, the difference is: the step 1) preparation of fracturing fluid: 0.25g of vegetable gum thickener, 0.30mL of drainage aid CF-5D, and 0.30mL of composite breaker FPJJ-1 0.01mL; the step 2) formation temperature is 50°C, the reaction temperature is 50°C, and the reaction time is 0.5 hours; the step 4) vegetable gum thickener is 0.05g, and the crosslinking agent JLJ-1 is 0.40 mL; the vegetable gum thickener is hydroxypropyl guar gum.

Embodiment 3

[0040] It is basically the same as Example 1, the difference is: the step 1) preparation of fracturing fluid: 0.3g of vegetable gum thickener, 0.50mL of drainage aid CF-5D, and 0.50mL of composite breaker FPJJ-1 0.02mL; the step 2) formation temperature is 100°C, the reaction temperature is 100°C, and the reaction time is 2 hours; the step 4) vegetable gum thickener is 0.15g, and the crosslinking agent JLJ-1 is 0.60 mL; the vegetable gum thickener is a mixture of guar gum and hydroxypropyl guar gum in a mass ratio of 1:1.

[0041]The vegetable gum thickener in the foregoing embodiments can also be one or more of guar gum, hydroxypropyl guar gum, and super guar gum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com