Clean fracturing fluid and preparation method thereof

A technology for cleaning fracturing fluid and glue, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting large-scale use, prone to "fish eyes, difficult to pump fluid, etc., and achieve low production costs" , the effect of strong complexation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

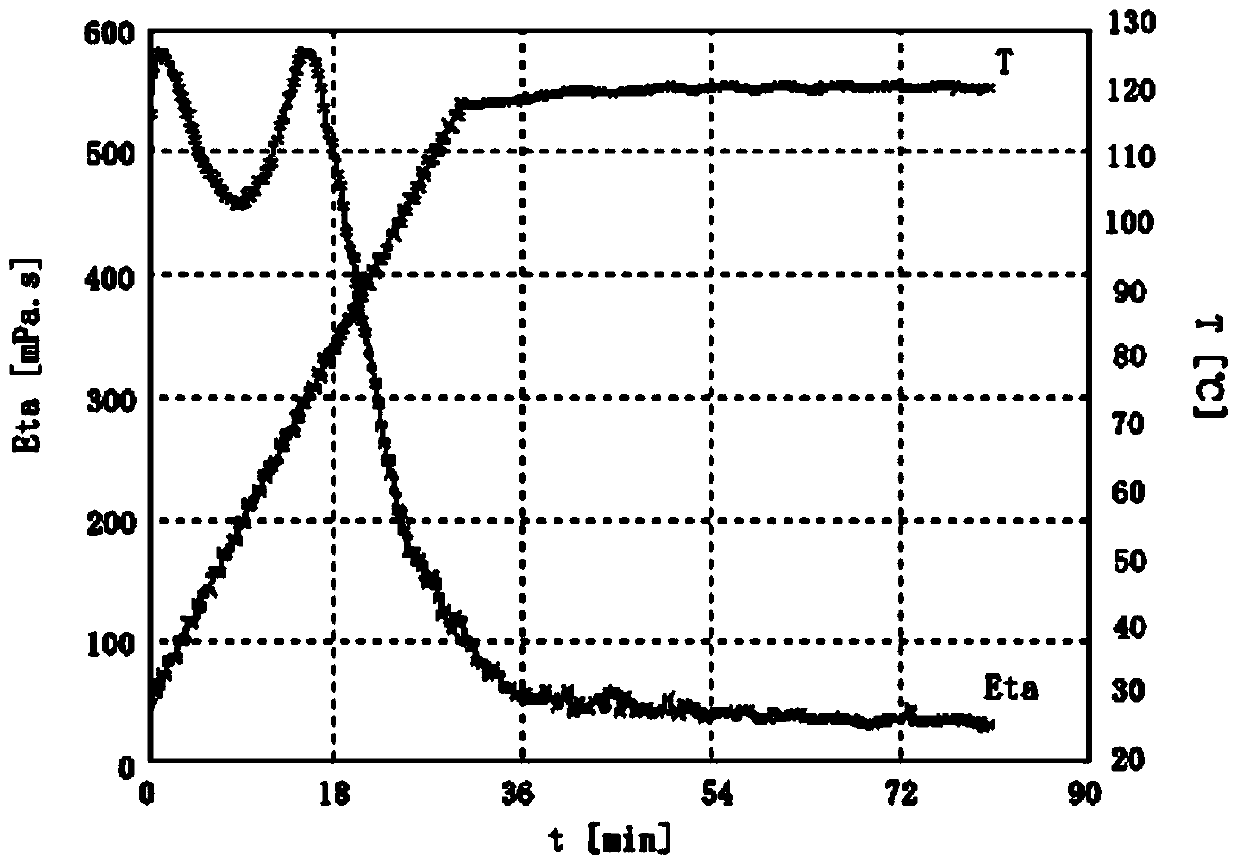

Image

Examples

Embodiment 1

[0032] The clean fracturing fluid of this embodiment is composed of raw gum solution, viscosity accelerator and gel breaker, and the raw gum solution is made of the following raw materials in mass percentage: 0.2% of hydrophobically associated polyacrylamide, 0.08% of organic acid , clay stabilizer 0.5%, and the balance is water; Described viscosity accelerator is made of the raw material of following mass percent: hexadecyl dihydroxyethyl amine oxide 0.15%, Gemini surfactant (sulfonate type Gemini surface active agent Activator) 0.3%, alkyl low-carbon alcohol 0.5%, pH regulator 0.15%, and the balance is water; the volume ratio of the original glue solution and the viscosity accelerator is 100:8, and the quality of the gel breaker is clean pressure 0.04% of the split liquid quality; the hydrophobic association polyacrylamide is FRAC-102 association thickener (purchased from Xi'an Kali Oilfield Technology Co., Ltd); the organic acid is petroleum sulfonic acid, and the clay is st...

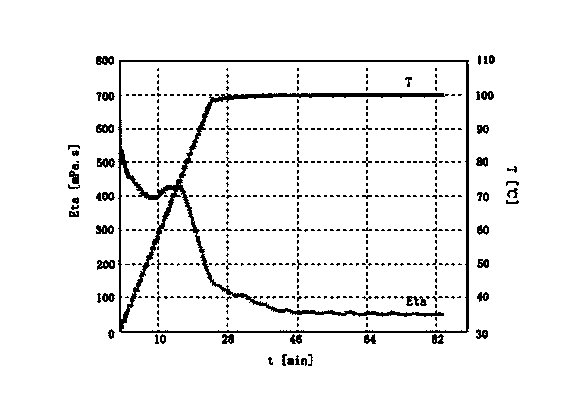

Embodiment 2

[0040] This example is the same as Example 1, except that the hydrophobic association polyacrylamide is FRA-313 association thickener (Beijing Freike Technology Development Company), GRF-1 association non- Cross-linked fracturing fluid thickener (Sichuan Guangya Polymer Chemical Co., Ltd.), CGR-7 associate thickener (Chengdu Jianxiang Shuguan Technology Co., Ltd.) or SXT102 fracturing thickener (Beijing Xitao Technology Development Co., Ltd.), the alkyl amine oxide is octadecyl dihydroxyethyl amine oxide, hexadecyl dimethyl amine oxide, octadecyl dimethyl amine oxide or octadecyl amidopropyl amine oxide Amines, the organic acid being fatty alcohol sulfuric acid, ethylenediaminetetraacetic acid, citric acid, oxalic acid or sulfamic acid, or petroleum sulfonic acid, fatty alcohol sulfuric acid, ethylenediaminetetraacetic acid, citric acid, oxalic acid and sulfamic acid At least two of them, the alkyl lower alcohol is butanol or amyl alcohol, the clay stabilizer is KCl, and the p...

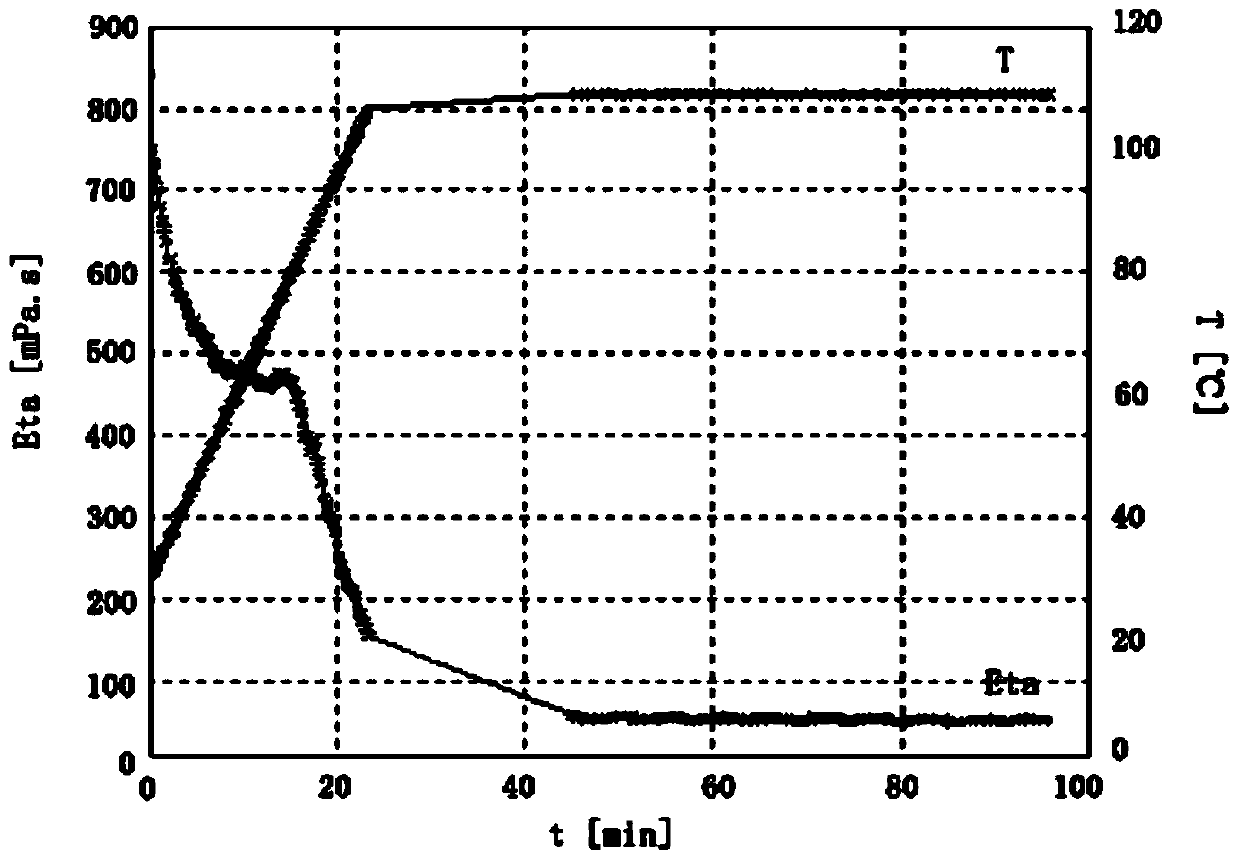

Embodiment 3

[0042] The clean fracturing fluid of this embodiment is composed of raw gum solution, viscosity accelerator and gel breaker, and the raw gum solution is made of the following raw materials in mass percentage: 0.3% of hydrophobically associated polyacrylamide, 0.1% of organic acid , clay stabilizer 0.6%, and the balance is water; Described viscosity accelerator is made of the raw material of following mass percent: hexadecyl dimethyl amine oxide 0.1%, Gemini surfactant (quaternary ammonium salt type Gemini surfactant agent) 0.2%, alkyl low-carbon alcohol 0.8%, pH regulator 0.3%, and the balance is water; the volume ratio of the original glue solution and the viscosity accelerator is 100:5, and the quality of the gel breaker is clean fracturing 0.03% of the liquid mass; the hydrophobic association polyacrylamide is GRF-1 association type non-crosslinked fracturing fluid thickener (purchased from Sichuan Guangya Polymer Chemical Co., Ltd); the organic acid is petroleum sulfonic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com