Preparation method of cathode active material of lithium ion battery

A cathode active material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as environmental pollution, increase costs, etc., and achieve the goal of reducing production costs, morphological rules, and stabilizing the formation rate of crystal nuclei. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

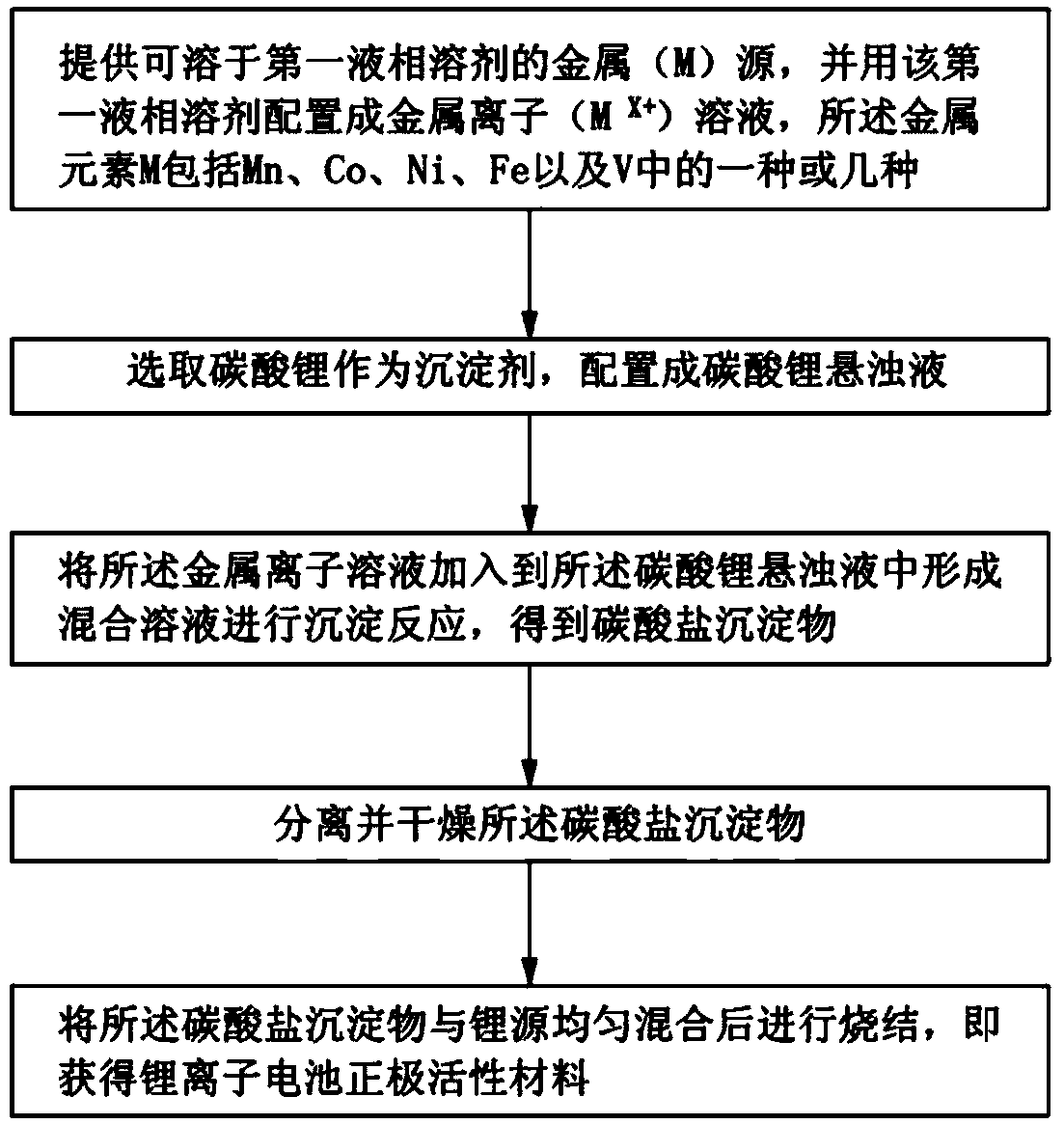

[0022] The embodiment of the present invention provides a kind of preparation method of positive electrode active material of lithium ion battery, it comprises the following steps:

[0023] S1, providing a metal (M) source soluble in the first liquid phase solvent, and using the first liquid phase solvent to configure metal ions (M x+ ) solution, the metal element M includes one or more of Mn, Co, Ni, Fe and V;

[0024] S2, select lithium carbonate as precipitating agent, be configured into lithium carbonate suspension;

[0025] S3, adding the metal ion solution to the lithium carbonate suspension to form a mixed solution for a precipitation reaction to obtain a carbonate precipitate;

[0026] S4, separating and drying the carbonate precipitate; and

[0027] S5, uniformly mixing the carbonate precipitate with the lithium source and then sintering to obtain the positive electrode active material of the lithium ion battery.

[0028] In the above step S1, the metal source may ...

Embodiment 1

[0045] (1) Weigh nickel sulfate and manganese sulfate respectively according to the molar ratio Ni:Mn=1:3, and dissolve them in deionized water to prepare a metal ion solution. The concentration of metal ions in the metal ion solution is 1.2mol / L;

[0046] (2) Disperse lithium carbonate with deionized water to form lithium carbonate suspension, the mass ratio of lithium carbonate to deionized water is 1:8;

[0047] (3) Place the above-mentioned lithium carbonate lithium carbonate suspension in a reactor, and at a stirring speed of 1000rpm, control the reaction temperature to 45°C, pump the metal ion solution into the reactor at a flow rate of 10ml / min for reaction, Obtain carbonate precipitates;

[0048] (4) separating the carbonate precipitate, and drying the carbonate precipitate at 100° C. for 10 hours;

[0049] (5) According to the content of Li, Ni, and Mn in the product of step (4), add LiOH at the ratio of Li:(Ni+Mn)=1.05:2 for uniform mixing and grinding, and heat tre...

Embodiment 2

[0053] (1) Weigh nickel sulfate, magnesium sulfate and manganese sulfate according to the molar ratio of Ni:Mg:Mn=0.48:0.02:1.5, and dissolve them in deionized water to prepare a metal ion solution. The concentration of the metal ion solution is 1.0mol / L;

[0054] (2) Disperse lithium carbonate with deionized water to form lithium carbonate suspension, the mass ratio of lithium carbonate to deionized water is 1:9;

[0055] (3) Place the above-mentioned lithium carbonate lithium carbonate suspension in a reactor, and at a stirring speed of 1000rpm, control the reaction temperature to 25°C, pump the metal ion solution into the reactor at a flow rate of 10ml / min for reaction, Obtain carbonate precipitates;

[0056] (4) separating the carbonate precipitate, and drying the carbonate precipitate at 100° C. for 10 hours;

[0057] (5) According to the content of Li, Ni, and Mn in the product of step (4), add LiOH according to the ratio of Li:(Ni+Mg+Mn)=1.05:2 for uniform mixing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com