Piezoelectric film electricity generator and manufacture method thereof

A technology of piezoelectric film and manufacturing method, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, generators/motors, etc. Problems such as difficulty in production, preparation and integration in the chemical industry, to achieve the effect of simplifying the preparation process, improving production efficiency, and achieving large-scale popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

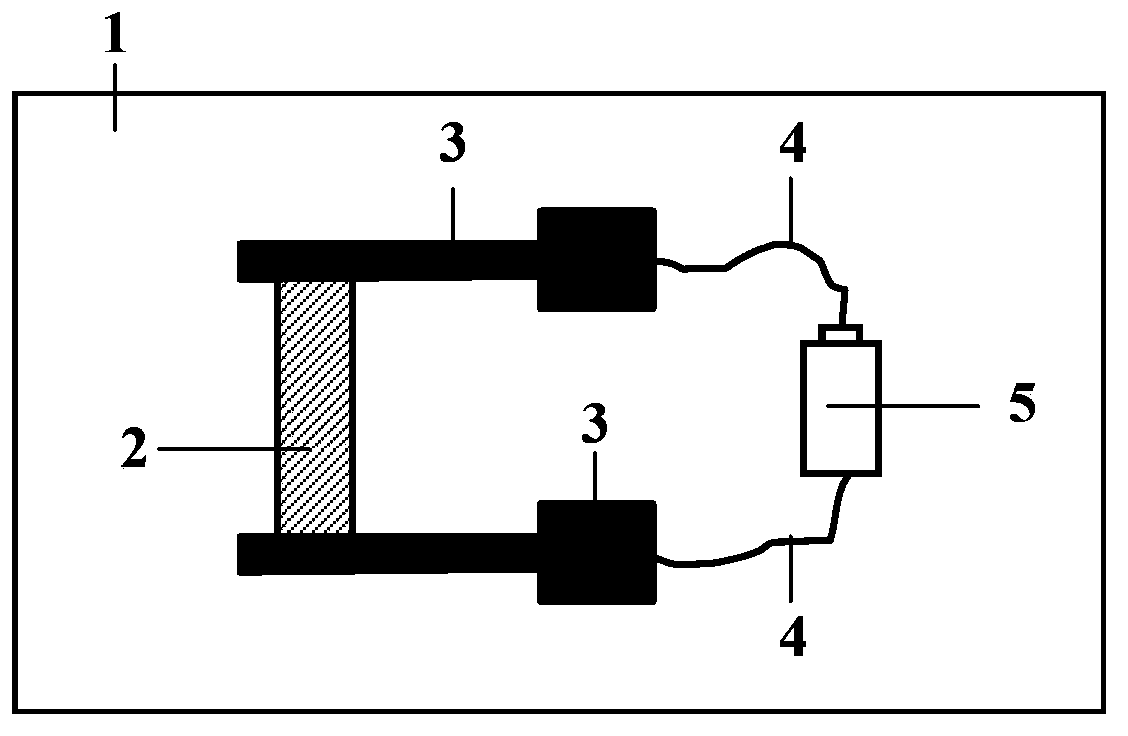

[0045] Such as figure 1 , the base 1 selects the thick cotton cloth of 1mm for use in the present embodiment; At room temperature, polyvinylidene fluoride (PVDF) piezoelectric polymer nanoparticles with a diameter of 200nm are added by weight ratio 50% to the substrate containing 0.25wt% gallium oxide. In the liquid gallium, a low-melting-point metal ink with certain fluidity is made, and then the low-melting-point metal ink is printed or coated on the surface of the substrate 1 in the form of lines to form a piezoelectric film 2 .

[0046] Afterwards, liquid gallium containing 0.25wt% gallium oxide is vertically printed or coated on the surface of the substrate 1 in the form of lines from the upper and lower ends of the piezoelectric film 2 at room temperature to form a thin film electrode 3 . The film electrodes 3 at both ends of the piezoelectric film 2 are connected by wires 4 to form a closed loop, and the electrical storage device 5 is connected to the closed loop wires ...

Embodiment 2

[0048] Such as figure 1 In this embodiment, the base 1 is made of cotton cloth with a thickness of 1mm; liquid gallium containing 0.25wt% gallium oxide is heated and mixed with pure zinc to form a low melting point alloy metal with a weight ratio of 0.2:0.8, and a low melting point alloy metal with a certain fluidity is made. Melting point metal ink, this low melting point metal ink is printed or coated on the substrate 1 surface in the form of line afterwards, forms alloy thin film (because it is an intermediate product, figure 2 not marked above); after that, move the alloy film coated with low melting point alloy ink together with the substrate 1 into a well-sealed oxygen bottle, raise the temperature to 200°C or higher, and keep it for 3 hours or longer, the alloy film is oxidized, and the zinc oxide in it has a piezoelectric effect, thereby forming a piezoelectric film 2; this oxidation process can also be realized by heating methods such as microwave, radio frequency, a...

Embodiment 3

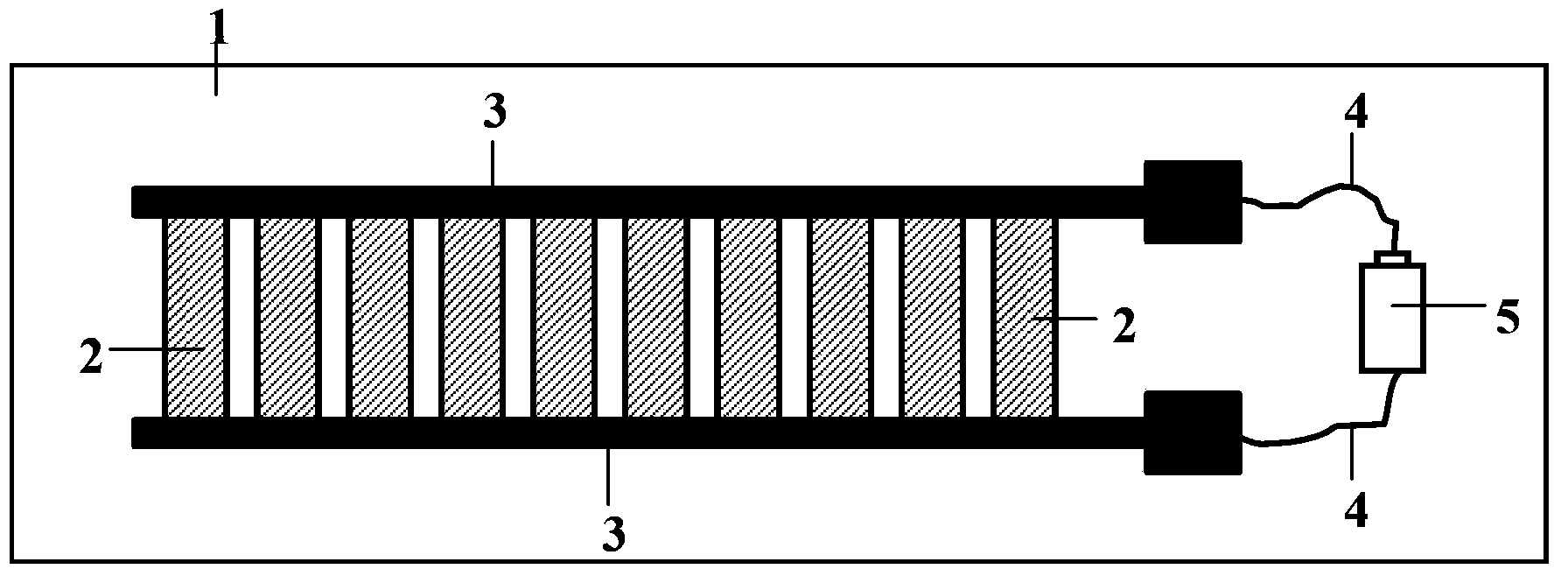

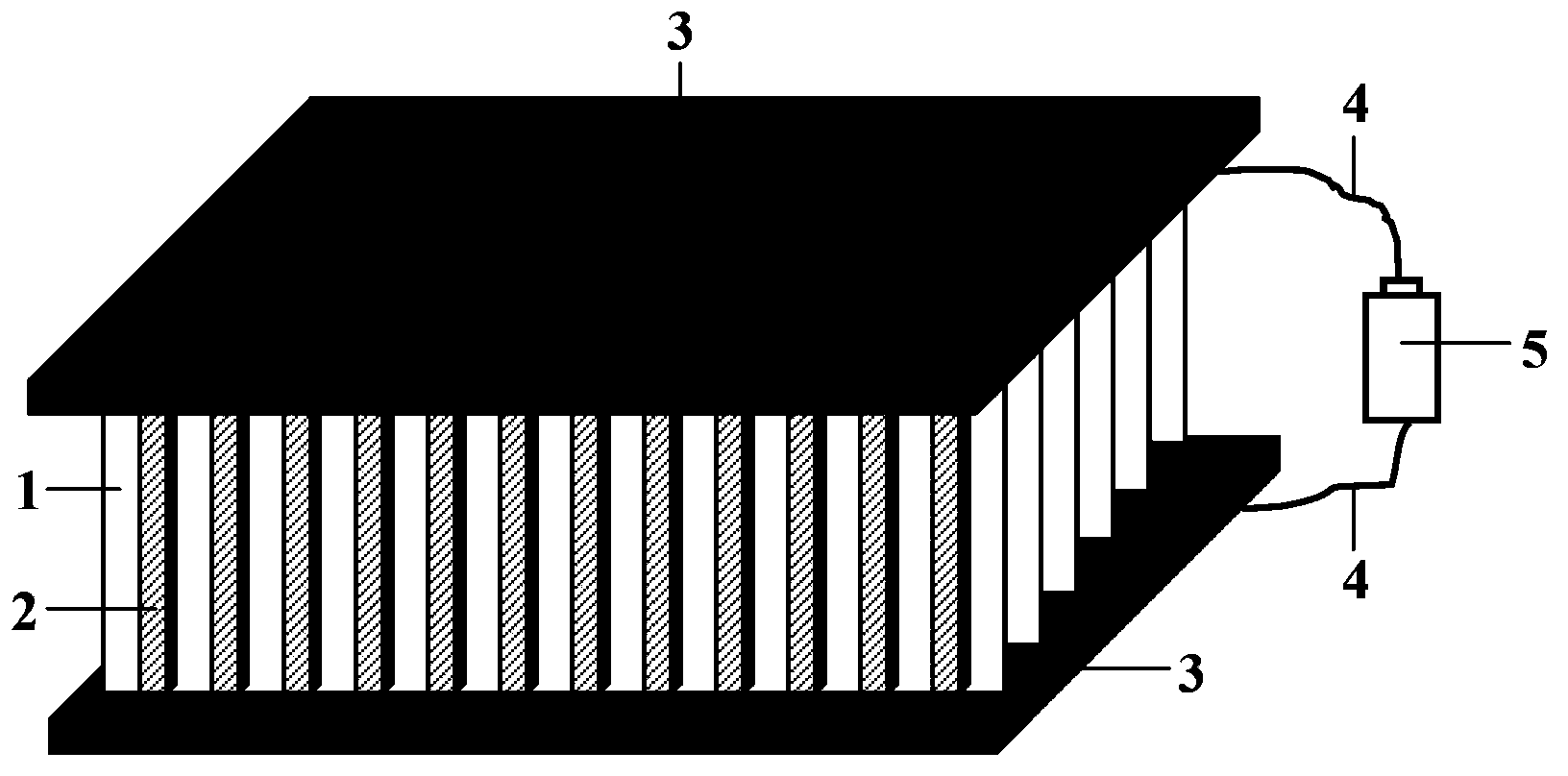

[0051] Such as figure 2 , different from Embodiment 1 and Embodiment 2, the piezoelectric generator of this embodiment is not only composed of a piezoelectric conversion circuit, but is composed of a plurality of piezoelectric films arranged in a row of conversion circuits, consisting of In this way, a larger amount of electric energy can be obtained, thereby better adapting to actual needs.

[0052] Substrate 1 is made of polyester cloth with a thickness of 1mm; at room temperature, polyvinylidene fluoride (PVDF) piezoelectric polymer nanoparticles with a diameter of 200nm are added to liquid gallium containing 0.25wt% gallium oxide by 50% by weight, A low-melting-point metal ink with a certain fluidity is made, and then the low-melting-point metal ink is printed or coated on the surface of the substrate 1 in the form of a line, and then 100 parallel piezoelectric films 2 are repeatedly printed at a certain interval, Thus, an aligned piezoelectric film is formed.

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com