Photosensitive resin composition, cured product and spacer

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, cured product and spacer, which can solve the problems of lower contrast of liquid crystal panel, lower substrate adhesion, light leakage, etc., and achieve excellent elastic recovery characteristics and tightness Synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

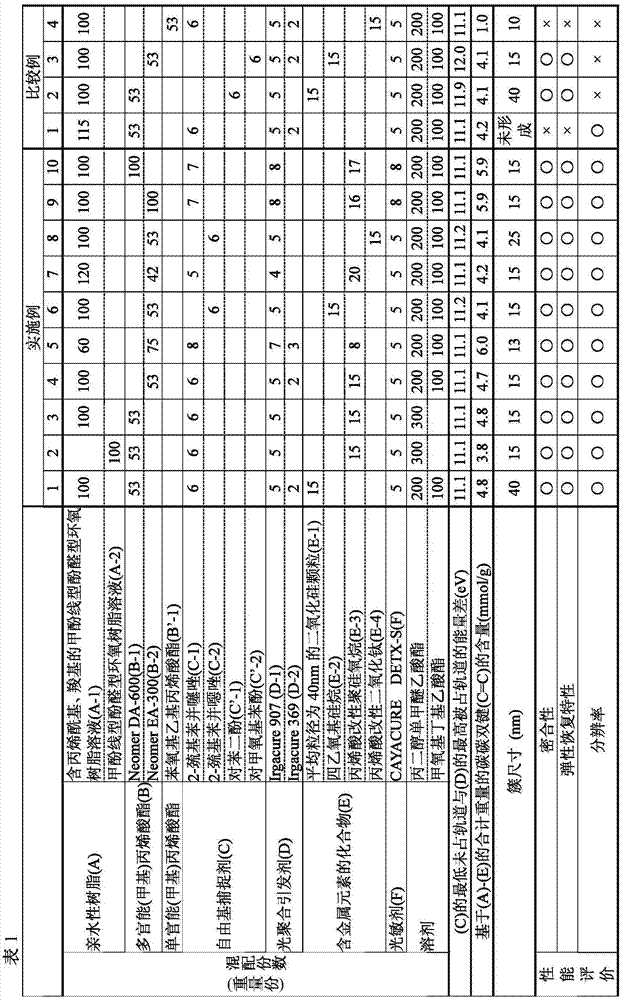

[0148] Hereinafter, the present invention will be further described by way of examples and comparative examples, but the present invention is not limited to these examples. Hereinafter, unless otherwise specified, % means % by weight, and part means parts by weight.

[0149] [Manufacture of hydrophilic resin]

manufacture example 1

[0151] A cresol novolac epoxy resin "EOCN-102S" (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent of 200) 200 parts and 245 parts of propylene glycol monomethyl ether acetate were heated to 110° C. and dissolved uniformly. Next, 76 parts (1.07 mol parts) of acrylic acid, 2 parts of triphenylphosphine, and 0.2 part of p-methoxyphenol were injected|thrown-in, and it was made to react at 110 degreeC for 10 hours. Further, 91 parts (0.60 mole parts) of tetrahydrophthalic anhydride were dropped into the reactant, and then reacted at 90°C for 5 hours, and then diluted with propylene glycol monomethyl ether acetate so that the content of the hydrophilic epoxy resin was 50% by weight, as a hydrophilic resin having an acryloyl group and a carboxyl group, a 50% solution (A-1) of a cresol novolac epoxy resin containing an acryloyl group and a carboxyl group was obtained.

[0152] In addition, in terms of pure components, the number average molecular weight (Mn) of this resin me...

manufacture example 2

[0154]In the same flask as Manufacturing Example 1, drop into 200 parts of cresol novolak epoxy resin "EOCN-102S" (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent is 200) and 200 parts of propylene glycol monomethyl ether acetate, Heat to 110°C and dissolve evenly. Afterwards, utilize propylene glycol monomethyl ether acetate to dilute so that the hydrophilic epoxy resin content is 50% by weight, have obtained the 50% solution (A- 2).

[0155] It should be noted that, in terms of pure components, the Mn of this resin is 1800, the SP value is 11.7, and the HLB value is 6.4.

[0156] [Production of a siloxane compound (E-3) having two or more hydrolyzable alkoxy groups]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com