Collapse prevention type polycarboxylic acid water reducing agent and preparation method thereof

A polycarboxylic acid and slump-preserving technology, which is applied in the field of concrete admixture and its preparation, can solve the problems of cumbersome operation, high energy consumption, and long time consumption, and achieve simple operation, short reaction cycle, and reduced slump loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

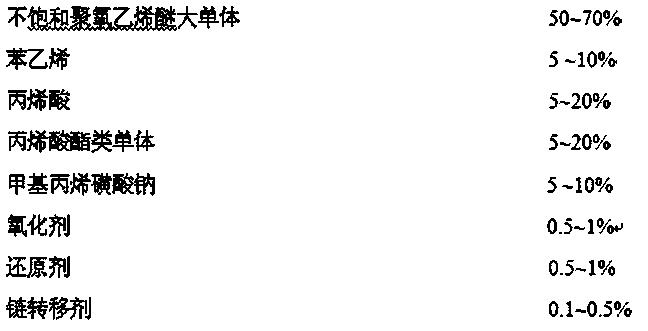

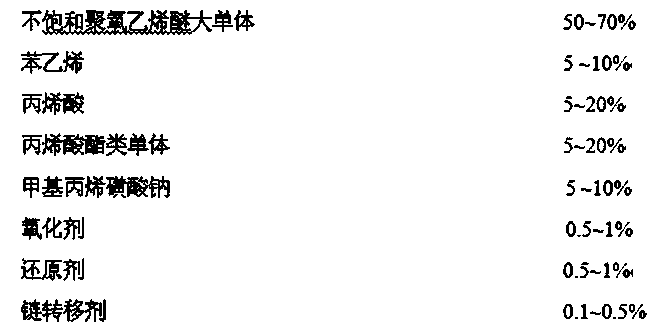

Method used

Image

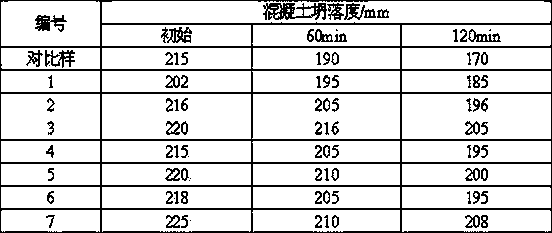

Examples

Embodiment 1

[0033] Take 120g of methallyl polyoxyethylene ether, 25g of styrene, 25g of sodium methacrylate sulfonate and 120g of deionized water, place them in a reaction kettle and stir the materials to dissolve completely. Then, the temperature was raised to 50°C while stirring, and the solution A and solution B were evenly added dropwise. The composition of solution A is a uniform solution composed of 35g acrylic acid, 25g hydroxyethyl acrylate and 30g deionized water; the solution B is a uniform solution composed of 1g sodium persulfate, 1g thioglycolic acid and 20g deionized water. The temperature in the reaction kettle was controlled at 50°C, and at the same time, solution A and solution B were added dropwise. Control the dropping time of A solution to 3h, and the dropping time of B solution to 4h. After the dropwise addition of the two solutions was completed, stirring was continued for 1.5 h for aging. After the above steps are completed, cool to about 30°C, add lye to adjust t...

Embodiment 2

[0035] Take 120g of methallyl polyoxyethylene ether, 25g of styrene, 25g of sodium methacrylate sulfonate and 120g of deionized water, place them in a reaction kettle and stir the materials to dissolve completely. Then, the temperature was raised to 60°C while stirring, and the A solution and the B solution were started to be added dropwise evenly. The composition of solution A is a uniform solution composed of 35g acrylic acid, 25g hydroxyethyl acrylate and 30g deionized water; the solution B is a uniform solution composed of 1g sodium persulfate, 1g thioglycolic acid and 20g deionized water. The temperature in the reactor was controlled at 60°C, and at the same time, solution A and solution B were added dropwise. Control the dropping time of A solution to 3h, and the dropping time of B solution to 4h. After the dropwise addition of the two solutions was completed, stirring was continued for 1.5 h for aging. After the above steps are completed, cool to about 30°C, add lye t...

Embodiment 3

[0037] Take 120g of methallyl polyoxyethylene ether, 25g of styrene, 25g of sodium methacrylate sulfonate and 120g of deionized water, place them in a reaction kettle and stir the materials to dissolve completely. Then, the temperature was raised to 70°C while stirring, and the solution A and solution B were evenly added dropwise. The composition of solution A is a uniform solution composed of 35g acrylic acid, 25g hydroxyethyl acrylate and 30g deionized water; the solution B is a uniform solution composed of 1g sodium persulfate, 1g thioglycolic acid and 20g deionized water. The temperature in the reaction kettle was controlled at 70°C, and at the same time, solution A and solution B were added dropwise. Control the dropping time of A solution to 3h, and the dropping time of B solution to 4h. After the dropwise addition of the two solutions was completed, stirring was continued for 1.5 h for aging. After the above steps are completed, cool to about 30°C, add lye to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com