Synthesis method of oxetanone

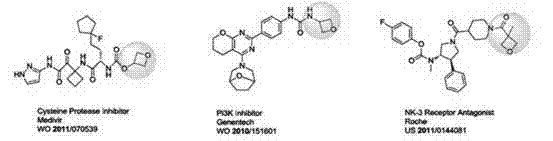

A technology of oxetanone and a synthesis method, applied in the formation/introduction of carbonyl group, organic chemistry and other directions, can solve the problems of less 3-oxetanone, hidden danger, high price and the like, and achieves improved reaction yield , the effect of reducing production costs and cheap materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

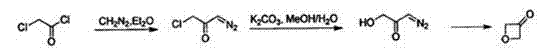

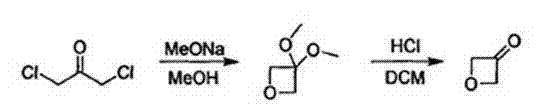

Method used

Image

Examples

Embodiment 1

[0048]Add 3 L of dichloromethane, 1.24 kg of TCCA, 1.28 kg of sodium bicarbonate, 33 g of potassium bromide and 8.7 g of TEMPO into a 5 L dry three-necked flask, stir and cool down to -5°C under nitrogen protection. Then 400 g of oxetanone was added dropwise. After the dropwise addition was complete, stirring was continued at 0°C for 2 hours. After filtering the reaction mixture, it was distilled under reduced pressure at room temperature to obtain 350 g of the product (purity greater than 95%), and the yield was 89%.

Embodiment 2

[0050] Add 2.0 L of dichloromethane, 770 kg of NCS, 710 kg of potassium bicarbonate, 150 g of tetrabutylammonium bromide and 15 g of TEMPO into a 5 L dry three-necked flask, stir and cool down to -5°C under nitrogen protection. Then 400 g of oxetanone was added dropwise. After the dropwise addition was complete, stirring was continued at 25°C for 4 hours. After the reaction mixture was filtered, it was distilled under reduced pressure at room temperature to obtain 320 g of the product (purity greater than 95%), with a yield of 82%.

Embodiment 3

[0052] Add 2.5 L of dichloromethane, 1.92 kg of NBS, 1.48 kg of potassium carbonate, 25 g of sodium bromide and 25 g of TEMPO into a 5 L dry three-necked flask, stir and cool down to 0 °C under nitrogen protection. Then 400 g of oxetanone was added dropwise. After the dropwise addition was complete, stirring was continued at 25°C for 4 hours. After the reaction mixture was filtered, it was distilled under reduced pressure at room temperature to obtain 335 g of the product (purity greater than 95%), with a yield of 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com