Modified coal asphalt product and preparation method thereof

A coal tar pitch modification technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor temperature stability, poor plasticity of coal tar pitch, irritating smell, etc., and achieve small footprint, save time, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

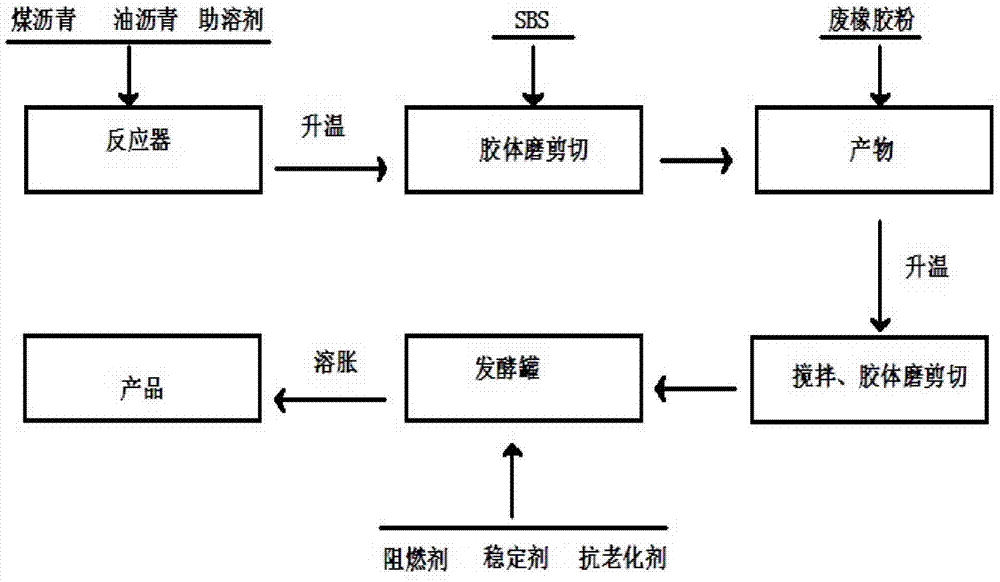

Method used

Image

Examples

Embodiment 1

[0023] (1) Put 50 parts of coal tar pitch, 10 parts of petroleum pitch and 200 parts of co-solvent into the reactor, raise the temperature to 150°C, add 1 part of linear SBS, and cut it with a colloid mill for 0.2 h;

[0024] (2) Add 5 parts of waste rubber powder to the sheared product, after heating, stir at 150 r / min and then shear with a colloid mill for 0.4 h.

[0025] (3) Send the product after the second shearing to the development tank, swell at 170°C and 15 r / min for 0.6h, then add 0.2 parts of stabilizer, 0.5 parts of flame retardant and 0.01 parts of anti The aging agent was developed for 0.6h to produce a modified coal tar pitch product.

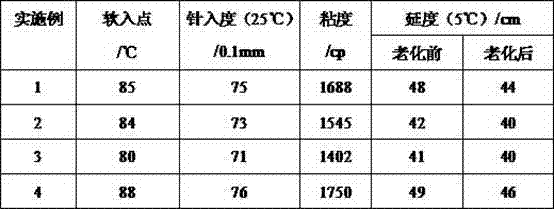

[0026] The performance of the coal tar pitch product modified in this embodiment is shown in Table 1.

[0027]

Embodiment 2

[0029] (1) First put 60 parts of coal tar pitch, 15 parts of petroleum pitch and 25 parts of co-solvent into the reactor, raise the temperature to 160°C, add 2 parts of star-shaped SBS, and cut it with a colloid mill for 0.3h;

[0030] (2) Add 5 to 35 parts of waste rubber powder to the sheared product, after heating, stir at 160 r / min and then shear with a colloid mill for 0.5h.

[0031] (3) Send the product after the second shearing to the development tank, swell at 175°C and 160 r / min for 0.8h, and then add 0.2 parts of stabilizer, 0.8 parts of flame retardant and 0.5 parts of anti The aging agent was developed for 0.8h to produce a modified coal tar pitch product.

[0032] The performance of the coal tar pitch product modified in this embodiment is shown in Table 1.

[0033]

Embodiment 3

[0035] (1) Put 80 parts of coal tar pitch, 20 parts of petroleum pitch and 30 parts of co-solvent into the reactor, raise the temperature to 180°C, add 4 parts of linear SBS, and cut it with a colloid mill for 0.4 h;

[0036] (2) Add 35 parts of waste rubber powder to the sheared product, after heating, stir at 300 r / min and then shear with a colloid mill for 0.6h.

[0037] (3) Send the product after the second shear to the development tank, swell at 180°C and 300 r / min for 1 hour, then add 0.3 parts of stabilizer, 1 part of flame retardant and 2 parts of anti-aging agent, and developed for 1h to obtain a modified coal tar pitch product.

[0038] The performance of the coal tar pitch product modified in this embodiment is shown in Table 1.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com