Antibacterial cement type plate and preparation method thereof

A quality board and cement technology, applied in the field of building decoration materials, can solve the problems of easy loss of drugs, low antibacterial efficiency, easy regeneration of bacteria, etc., and achieve the effects of solving bacterial growth, high antibacterial performance and poor antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the preparation method of the antibacterial cementitious board comprises the following steps:

[0031] Take a cement board, and first sand the cement board; in this way, the flatness of the board can be increased, which is conducive to the adhesion of the paint layer;

[0032] Select one side as the back side of the cementitious board, first put one layer of back primer on the back side of the cementitious board, dry and solidify; the back primer is UV paint, because this side is directly in contact with the building wall, through Adding this layer of UV paint can increase the waterproof and moisture-proof performance of the board, and can prevent the board from cracking due to the tension formed when the board is painted on the front;

[0033] Do a penetrating primer (penetration sealing primer) treatment on the front of the cement board, dry and cure; the purpose of this penetrating primer treatment is to increase the waterproof performance of the board ...

Embodiment 1

[0047] Take a calcium silicate board, sand its surface, and apply a layer of back primer 20g / m on the back of the calcium silicate board2 , UV curing; and then a layer of penetrating primer 75g / m on the front 2 , UV curing; putty treatment again; and then a layer of sealing primer 50g / m 2 , UV curing; sanding treatment; and then a layer of white primer 100 g / m 2 , UV curing; sanding treatment; and then a layer of super white paint 20mg / m 2 , UV curing; and then a layer of blue paint, UV curing. Wherein, the back primer, penetrating primer, sealing primer, white primer, ultra-white paint and blue color paint are all added with nano-acrylic acid ester and silver-based antibacterial agent before construction, and nano-acrylic acid ester accounts for each coating respectively. 5% by weight, and silver-based antibacterial agents accounted for 1% by weight of each coating.

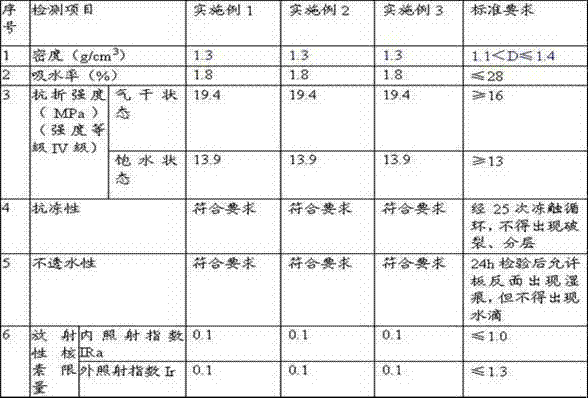

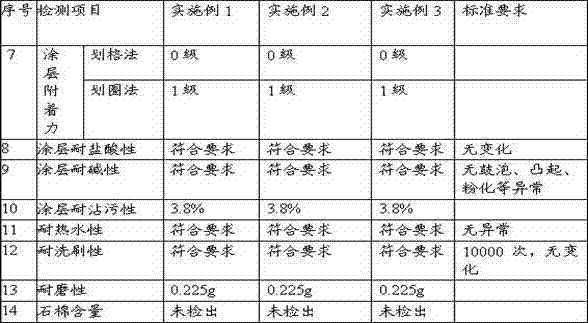

[0048] The parameters such as antibacterial and wear resistance were tested respectively, and the results ...

Embodiment 2

[0050] Take a fiber cement board, sand its surface, and apply a layer of back primer 30g / m on the back of the fiber cement board 2 , cured by ultraviolet light; and then a layer of penetrating primer 60g / m2 on the front 2 , UV curing; putty treatment again; and then a layer of sealing primer 55g / m 2 , UV curing; sanding treatment; and then a layer of white primer 90 g / m 2 , UV curing; sanding treatment; and then a layer of super white paint 25mg / m 2 , UV curing; and then a layer of pink paint, UV curing. Wherein, the back primer, penetrating primer, sealing primer, white primer, ultra-white paint and color paint are all added with nano-acrylic acid ester and silver-based antibacterial agent before construction, and nano-acrylic acid ester accounts for the weight of each coating respectively. 2% of each coating, and silver-based antibacterial agents accounted for 0.5% of the weight of each coating.

[0051] The parameters such as antibacterial and wear resistance were teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com