Novel cesium iodide scintillation screen

A cesium iodide and scintillation screen technology, which is applied in the direction of conversion screen, photography technology, X-ray/infrared technology, etc., can solve the problems affecting the MTF value of the scintillation screen, the complex preparation process of the scintillation layer, and the reduction of image contrast, etc., to achieve excellent MTF value, unique features, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

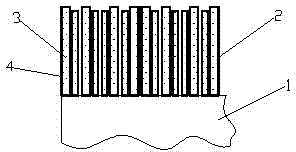

Image

Examples

Embodiment

[0017] Concrete preparation process is as follows:

[0018] a) Select the bottom layer, the bottom layer is made of glass or optical fiber panel, and its thickness is about 1.5-1.8mm; the bottom layer needs to be cleaned ultrasonically before use, and then dried after cleaning;

[0019] b) Prepare the cesium iodide layer. The cesium iodide layer is prepared by vacuum thermal evaporation process. The preparation process is as follows: first, weigh the cesium iodide powder quantitatively, and place the powder in the evaporation boat, and the evaporation boat and the bottom layer The distance between them is controlled at 15-20cm; then, the evaporation chamber is evacuated, and the vacuum degree is controlled at 10 -10 torr, the bottom layer is heated to 220°C-240°C with electric heating wire; then, turn on the power of the evaporation boat, and after the temperature of the evaporation boat rises to 440°C-480°C, argon gas is introduced, and the airflow velocity of argon gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com