Energy storage device and assembling method thereof

An energy storage device and negative electrode technology, which is applied in the direction of hybrid box/housing/package, hybrid capacitor collector, hybrid capacitor terminal, etc., can solve the problem that the sealing effect is greatly affected by the assembly process, the lead wire of the electrode unit is easily damaged, and the single O-type low cost of processing and molding, improved reliability, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

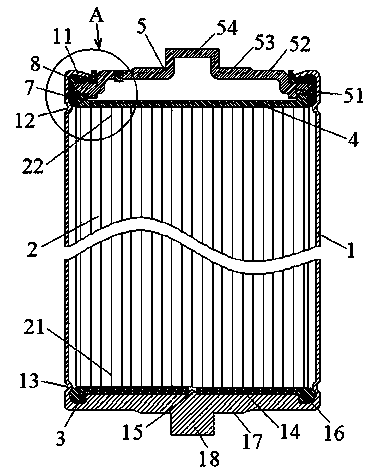

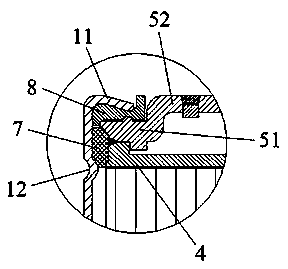

[0064] Please refer to figure 1 , figure 1 It is a schematic diagram of the cross-sectional structure of the energy storage device. The energy storage device includes a casing 1, a battery cell 2, a positive inner terminal 3, a negative inner terminal 4, a negative outer terminal 5 and an electrolyte. The casing 1 is cylindrical, and the electrolyte, the battery cell 2 , the positive inner terminal 3 and the negative inner terminal 4 are located inside the casing 1 . The bottom of the case 1 serves as the positive outer terminal, which is in contact with the positive inner terminal 3 . The housing 1 is made of metal or alloy, preferably aluminum or its alloy. An explosion-proof valve is also provided on the side wall of the housing 1, which is not shown in the figure.

[0065] The positive inner terminal 3 and the negative inner terminal 4 are respectively welded on the end faces of the positive electrode 21 and the negative electrode 22 of the cell 2 . The positive inner...

Embodiment 2

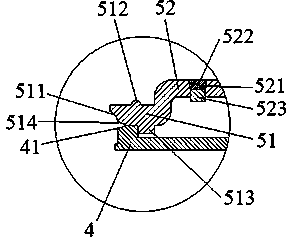

[0073] Please refer to Figure 5 , Figure 5 It is a partial structural diagram of another embodiment of the energy storage device of the present invention. In this embodiment, the energy storage device differs from the energy storage device in Embodiment 1 in that:

[0074] The cross-section of the downward positioning body 513 is triangular, which also has a good positioning effect; in this embodiment, the downward positioning body 513 is divided into four sections as a whole, and the four sections are symmetrically arranged in a ring shape;

[0075] The outer peripheral side 511 is an outwardly curved surface, which can increase the compression ratio of the O-ring 7;

[0076] The middle part of the S-shaped cross-section of the sealing gasket 8 is narrower. At this time, the inner wall of the curling edge 11 of the mouth of the housing 1 is a plane, and the sealing effect is better.

Embodiment 3

[0078] A method for assembling an energy storage device, comprising the steps of:

[0079] Step 1, welding and fixing the positive inner terminal 3 and the negative inner terminal 4 on the end surfaces of the positive pole 21 and the negative pole 22 of the battery cell 2 respectively;

[0080] Step 2, combining the negative external terminal 5 and the negative internal terminal 4 together by pressing in, the lower surface of the negative external terminal 5 and the upper surface of the negative internal terminal 4 are bonded together to form a joint;

[0081] Step 3, welding the joint, so that the negative outer terminal and the negative inner terminal form an assembly;

[0082] Step 4, set an O-shaped sealing ring 7 and a sealing gasket 8 on the outer periphery of the assembly;

[0083] Step 5, insert the positive inner terminal 3, the battery cell 2, the negative inner terminal 4, the negative outer terminal 5, the O-ring 7 and the gasket 8 into the housing 1 as a whole; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com