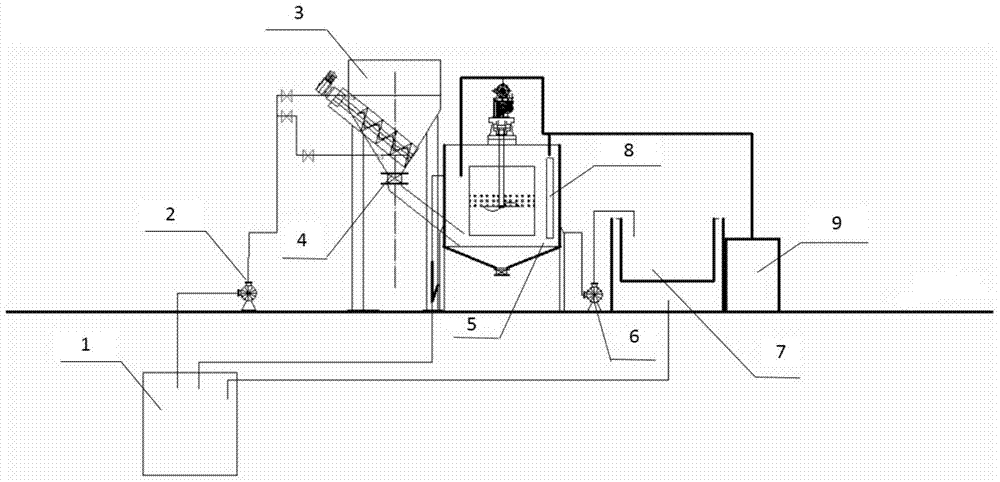

Equipment and method for ultrasonically enhanced restoration of soil in organically polluted sites

A technology of organic pollution and ultrasonic enhancement, applied in the restoration of polluted soil, etc., can solve problems such as equipment research that has not been reported, and achieve the effect of reducing labor input, wide application and reasonable treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

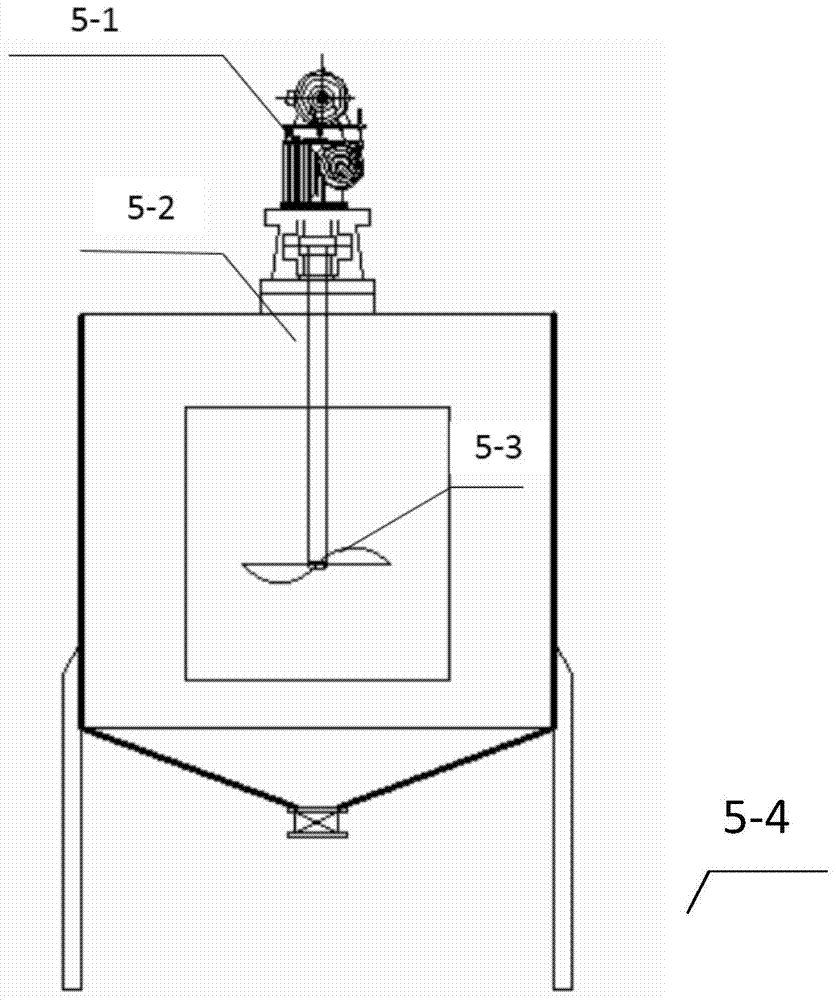

Method used

Image

Examples

Embodiment 1

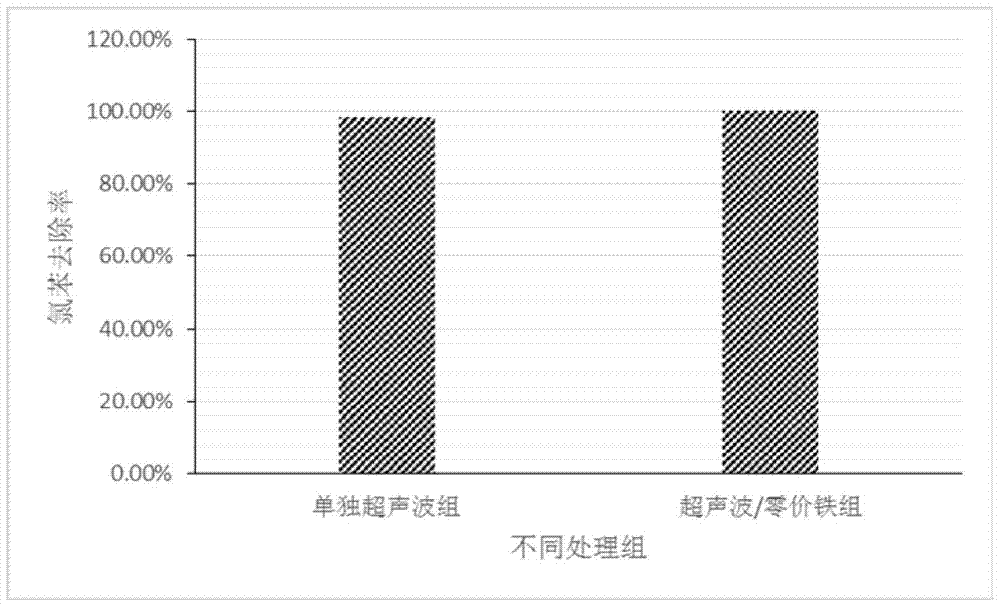

[0032] The soil in the pilot test is artificially polluted. Take 20cm of soil from the surface of the farmland, and then pollute it with a chlorobenzene solution dissolved in acetone at a concentration of 150mg kg -1 .

[0033]The pilot experiment was divided into two treatment groups, namely ultrasonic treatment alone and ultrasonic / zero-valent iron synergistic treatment. The amount of soil in each group was 50kg, the water-to-soil ratio was 3:1, and the amount of zero-valent iron in the ultrasonic / zero-valent iron treatment group was 100g. . The operating parameters of the pilot equipment are: ultrasonic power 1200W, stirring rate 300r / min, ultrasonic treatment time 90min. The automatic control device is used to control the running time of ultrasonic and stirring devices, and the running time of ultrasonic device and stirring device is set to 90 minutes, and the equipment will stop automatically after reaching the total running time. After the operation, mud samples were c...

Embodiment 2

[0036] The experimental soil was taken from the soil of a pesticide factory polluted site.

[0037] Under the condition of ultrasonic / zero-valent iron co-treatment, in order to explore the effect of the amount of zero-valent iron on the removal efficiency of pollutants in soil, three groups of experiments were set up, and the amount of zero-valent iron was 300g, 600g and 900g respectively. The amount of soil used in each experiment was 50kg, and the ratio of water to soil was 3:1. The operating parameters of the pilot equipment are: ultrasonic power 1200W, 2400W, 3600W, stirring rate 300r / min, ultrasonic treatment time 60min, 75min, 90min. The automatic control device is used to control the time of ultrasonic operation and stirring, set the operating time of the ultrasonic device and the stirring device, automatically start the ultrasonic device and the stirring device, and automatically stop the equipment after reaching the total operating time. After the separation of mud a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com