Special solid corrosion and scale inhibitor for oilfield reinjection water

A technology of corrosion and scale inhibitor, oil field re-injection water, applied in descaling and water softening, complex/solubilizer treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing packaging storage sites and managing transportation costs , the concentration of aqueous solution should not be adjusted, and the cost of material transportation will be increased, so as to facilitate packaging, storage, transportation and use, reduce recycling and transportation costs, and achieve good scale inhibition effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

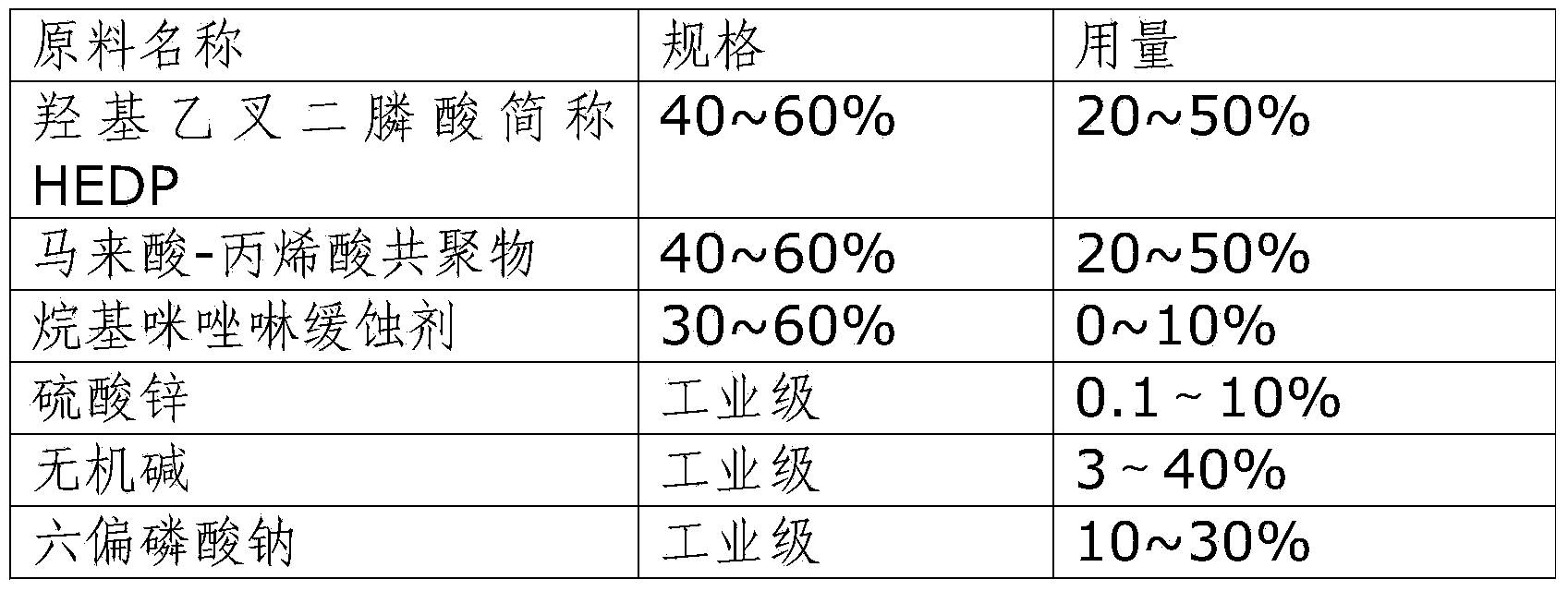

[0036] Embodiment 1, a special solid corrosion and scale inhibitor for oil field reinjection water, is a product made of the following raw materials in the following weight percentages, using the following preparation method:

[0037]

[0038] The preparation method of solid corrosion and scale inhibitor for oilfield reinjection water comprises the following steps:

[0039] (1). Add hydroxyethylidene diphosphonic acid (HEDP), maleic acid-acrylic acid copolymer, and alkylimidazoline corrosion inhibitor into the kneader, and stir evenly at room temperature.

[0040] (2). Add inorganic alkali in batches, neutralize to pH=6~8, after adding, knead and stir at room temperature for 25~30 minutes,

[0041] (3). Heating to 100-130°C, kneading, stirring and drying until the moisture content is 20%-30%,

[0042] (4). The material is shaped and dried by a screw extruder,

[0043] (5). Add zinc sulfate and sodium hexametaphosphate, stir and mix for 25-30 minutes to get the finished pr...

Embodiment 2

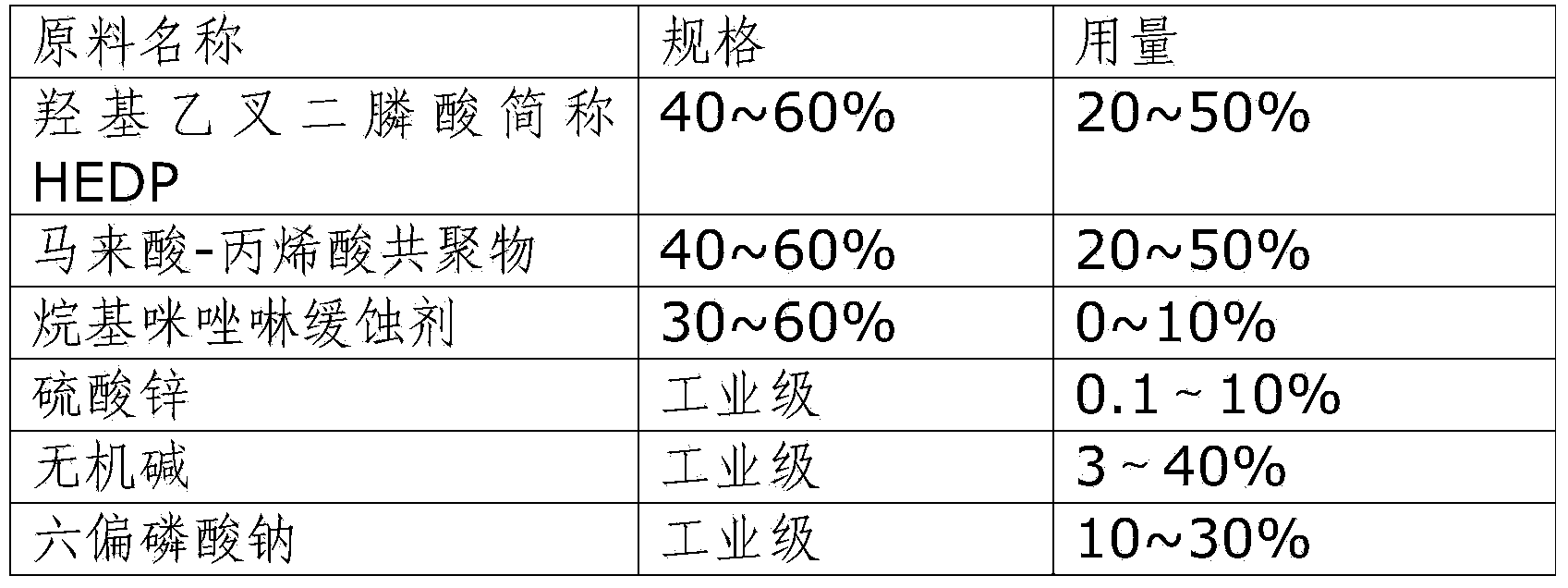

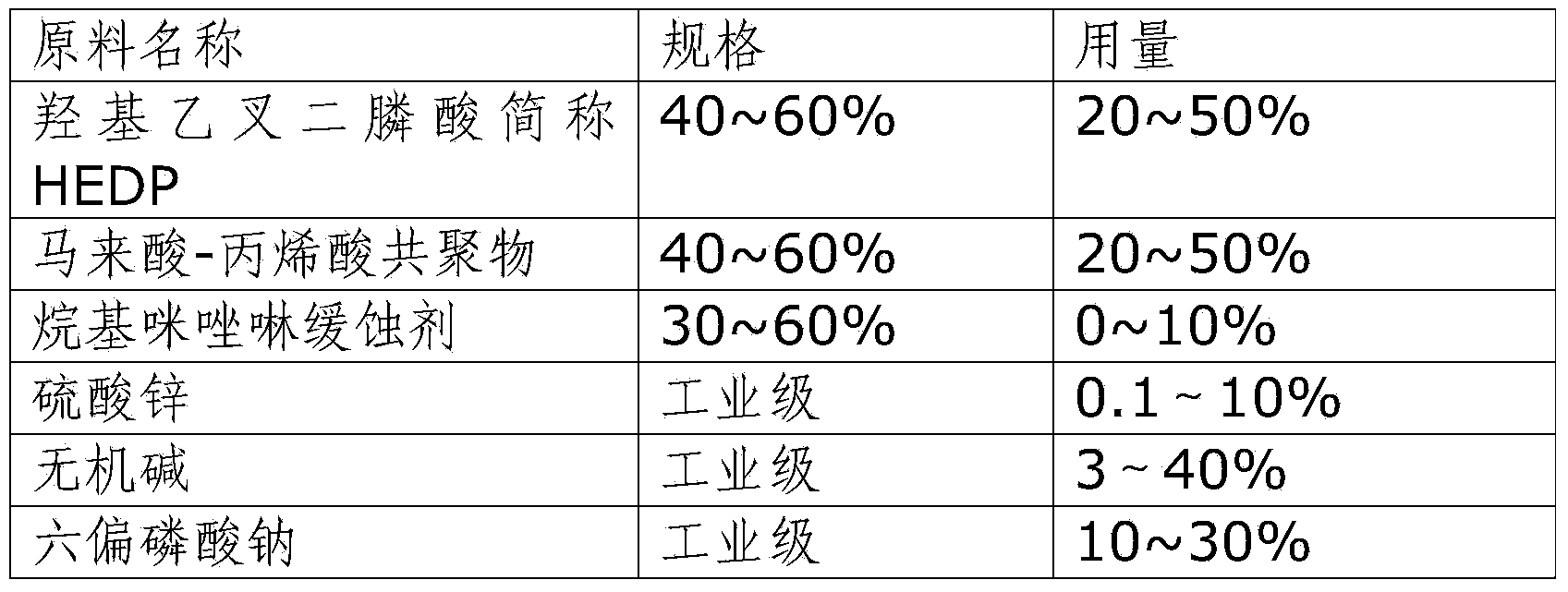

[0049] Embodiment 2, a special solid corrosion and scale inhibitor for oilfield reinjection water, is a product made of the following raw materials in the following weight percentages, using the following preparation method:

[0050]

[0051]The preparation method of solid corrosion and scale inhibitor for oilfield reinjection water comprises the following steps:

[0052] (1). Add hydroxyethylidene diphosphonic acid (HEDP), maleic acid-acrylic acid copolymer, and alkylimidazoline corrosion inhibitor into the kneader, and stir evenly at room temperature.

[0053] (2). Add inorganic alkali in batches, neutralize to pH=6~8, after adding, knead and stir at room temperature for 25~30 minutes,

[0054] (3). The material is shaped and dried by a screw extruder,

[0055] (4). Add zinc sulfate and sodium hexametaphosphate, stir and mix for 25-30 minutes to get the finished product.

[0056] The specification requirements of the raw materials used in this embodiment are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com