High-whiteness, halogen-free, flame-retardant, thermal conductive and insulated PA 6 (polyamide 6)-based composite material and preparation method thereof

A heat-conducting insulation and composite material technology, applied in high whiteness halogen-free flame retardant heat-conducting insulation PA6-based composite material and its preparation, in the field of PA6-based composite material, to achieve good flame retardant performance, increased thermal insulation and oxygen insulation, and flow processing. Sexual improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

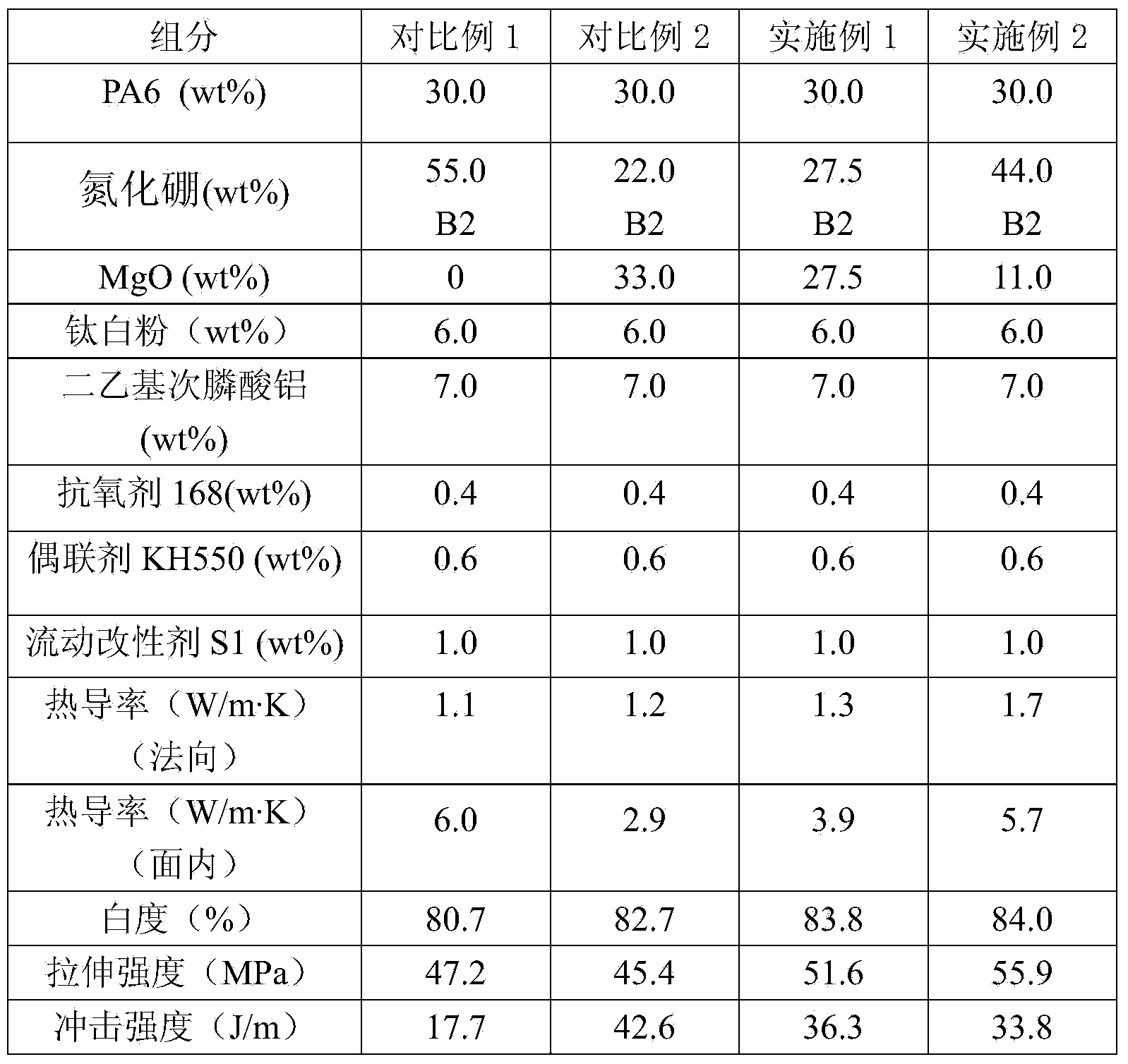

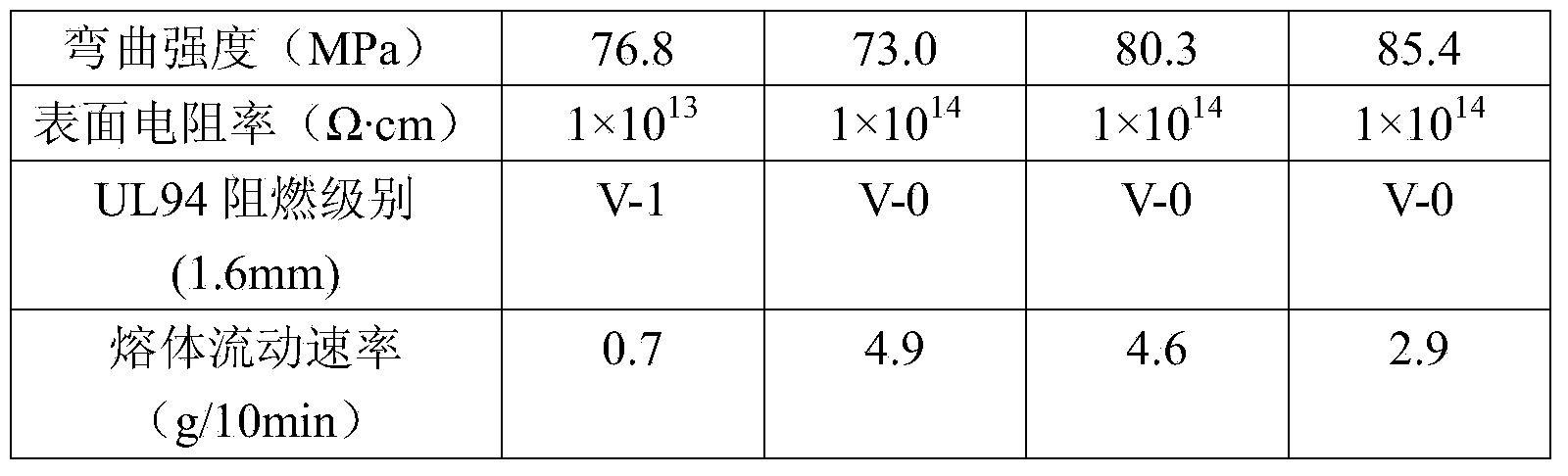

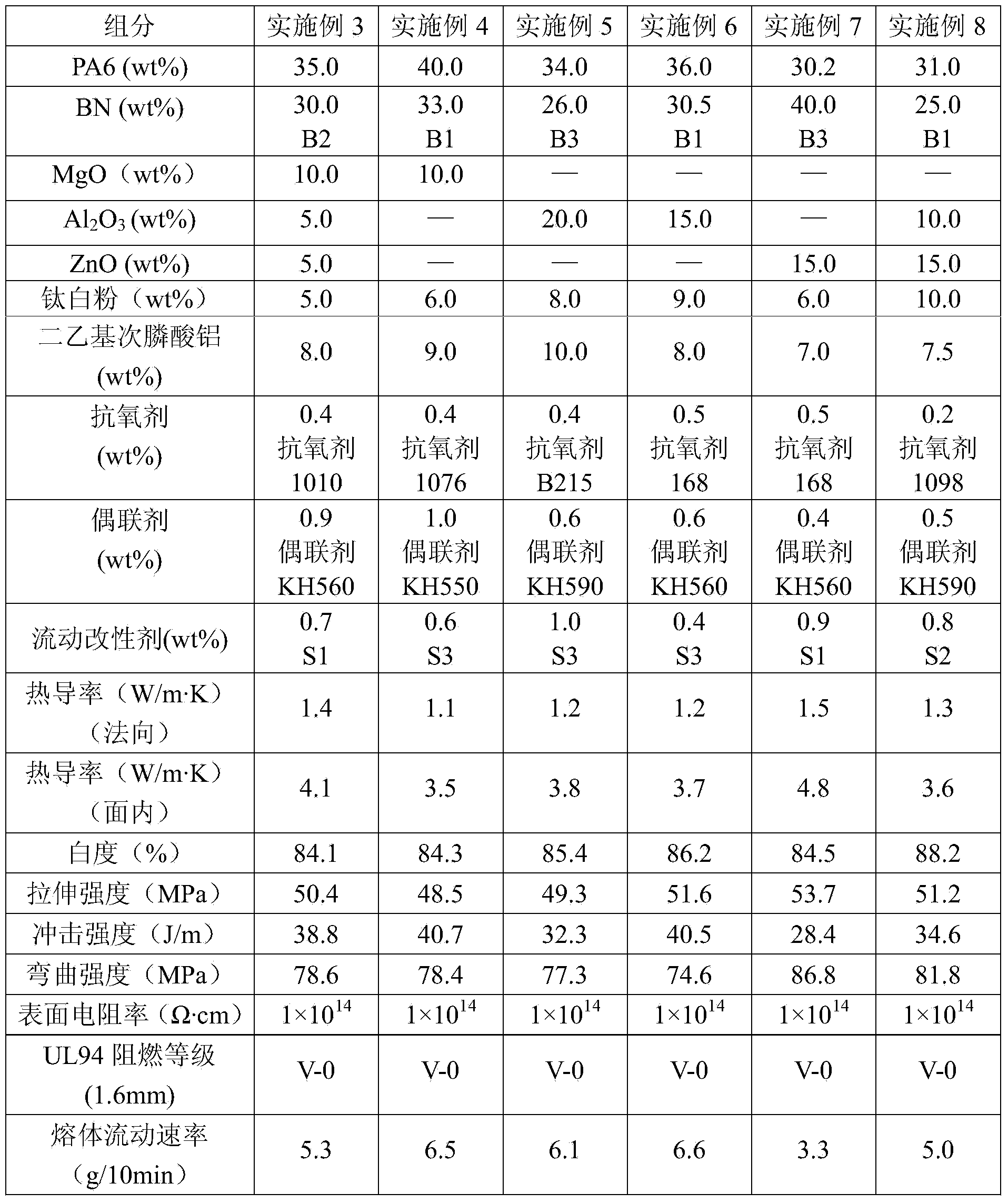

Embodiment 1

[0023] The total amount of control is 3Kg, 30wt% PA6, 27.5wt% BN, 27.5wt% MgO, 6wt% titanium dioxide, 7wt% aluminum diethylphosphinate, 0.4wt% antioxidant 168, 0.6wt% coupling agent KH550, 1wt% flow modifier S1 is added to the high-speed mixer, and after stirring and mixing at room temperature, the obtained premix is melted, kneaded, extruded, cooled, and cut at a temperature of 220°C to 240°C through a twin-screw extruder. Granulated and dried to obtain a high-whiteness halogen-free flame-retardant thermal-conductive insulating PA6-based composite material. The ratio of each raw material was changed, and the other 7 examples and 2 comparative examples of the present invention were prepared according to the method of Example 1.

[0024] After the prepared composite material was baked at 110°C for 3 hours, it was injection molded into Φ80×1mm, Φ12.7×1.0mm discs for testing resistivity and thermal conductivity, and injection molded into 100.0×50.0×2.5mm square discs and The 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com