Modified talc for interior decoration coating and preparation method of modified talc

An interior decoration and modification technology, which is applied in the field of modified talc for interior decoration coatings and its preparation, can solve the problems of ineffective removal of toxic gases and the like, and achieve the effects of easy water dispersion, good fluidity and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

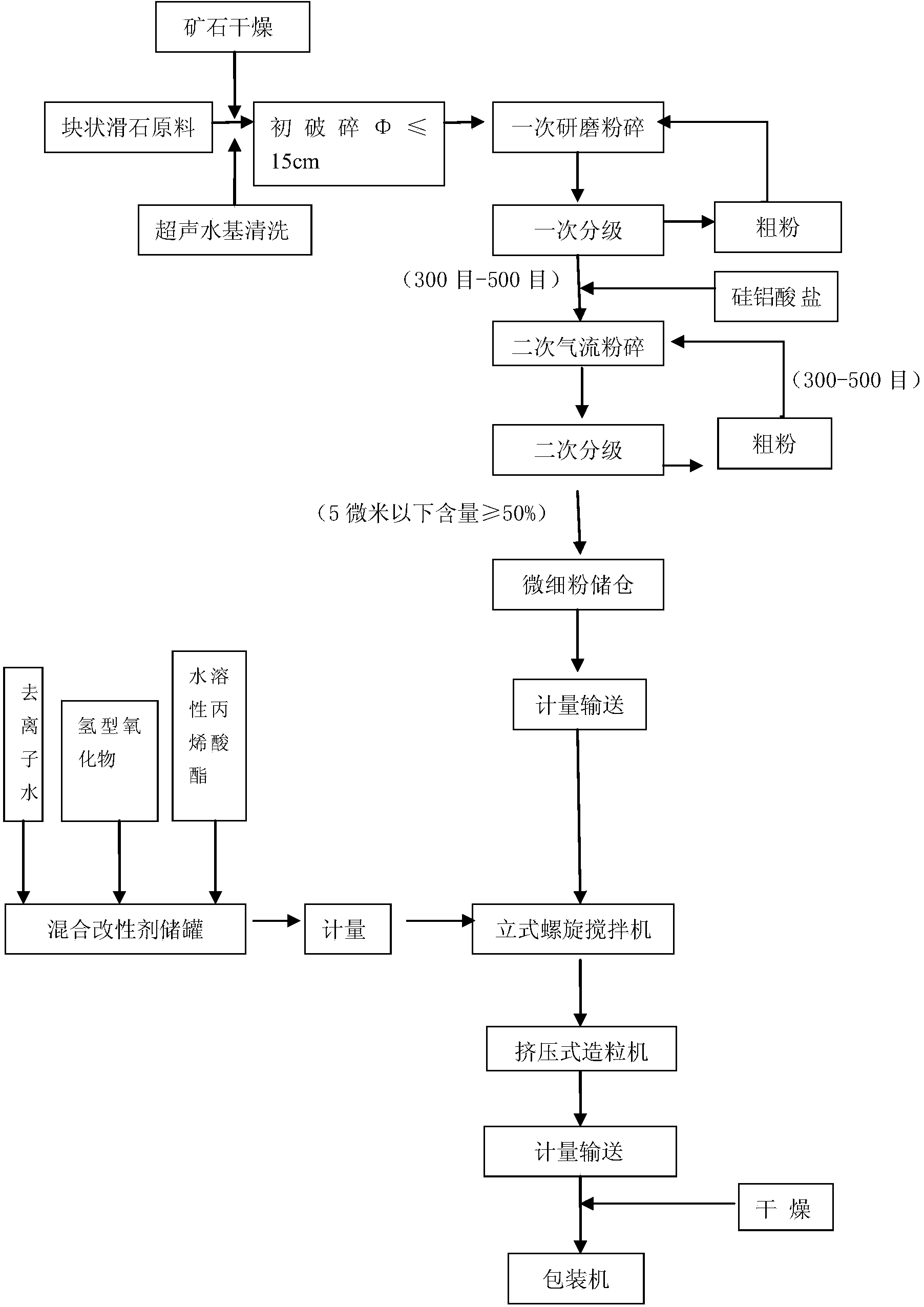

Method used

Image

Examples

Embodiment 1

[0032] A kind of modified talc for interior decoration paint, its mineral composition is by weight percentage: 80% of natural talc, 10% of aluminosilicate, 10% of modifier; In the composition of modifier, by its own weight, Hydrogen zinc oxide accounts for 50%, water-soluble acrylate accounts for 20%, and deionized water accounts for 30%.

Embodiment 2

[0034] A kind of modified talc for interior decoration paint, its mineral composition is by weight percentage: natural talc 85%, aluminosilicate 7%, modifier 8%; In the composition of modifier, by its own weight, Hydrogen magnesium oxide accounts for 30%, water-soluble acrylate 30%, and deionized water 40%.

Embodiment 3

[0036] A kind of modified talc for interior decoration paint, its mineral composition is by weight percentage: natural talc 82%, aluminosilicate 9%, modifier 9%; In the composition of modifier, by its own weight, Hydrogen titanium oxide accounts for 40%, water-soluble acrylate accounts for 30%, and deionized water accounts for 30%.

[0037] The composition of natural talc in the above-mentioned embodiment is monoclinic hydrated magnesium silicate, and its specific gravity is 2.7~2.8g / cm 3 ; Aluminosilicate, its main component is the sodium salt of aluminosilicate, with a density of 2.75-3.1g / cm 3 The hydrogen oxide is one or more of hydrogen zinc oxide, hydrogen titanium oxide or hydrogen magnesium oxide; the particle size of the water-soluble acrylate is not more than 200 nanometers, and the pH value is 7-9. The rotational viscosity is not less than 100 centipoise, and the glass transition temperature is -10~5℃.

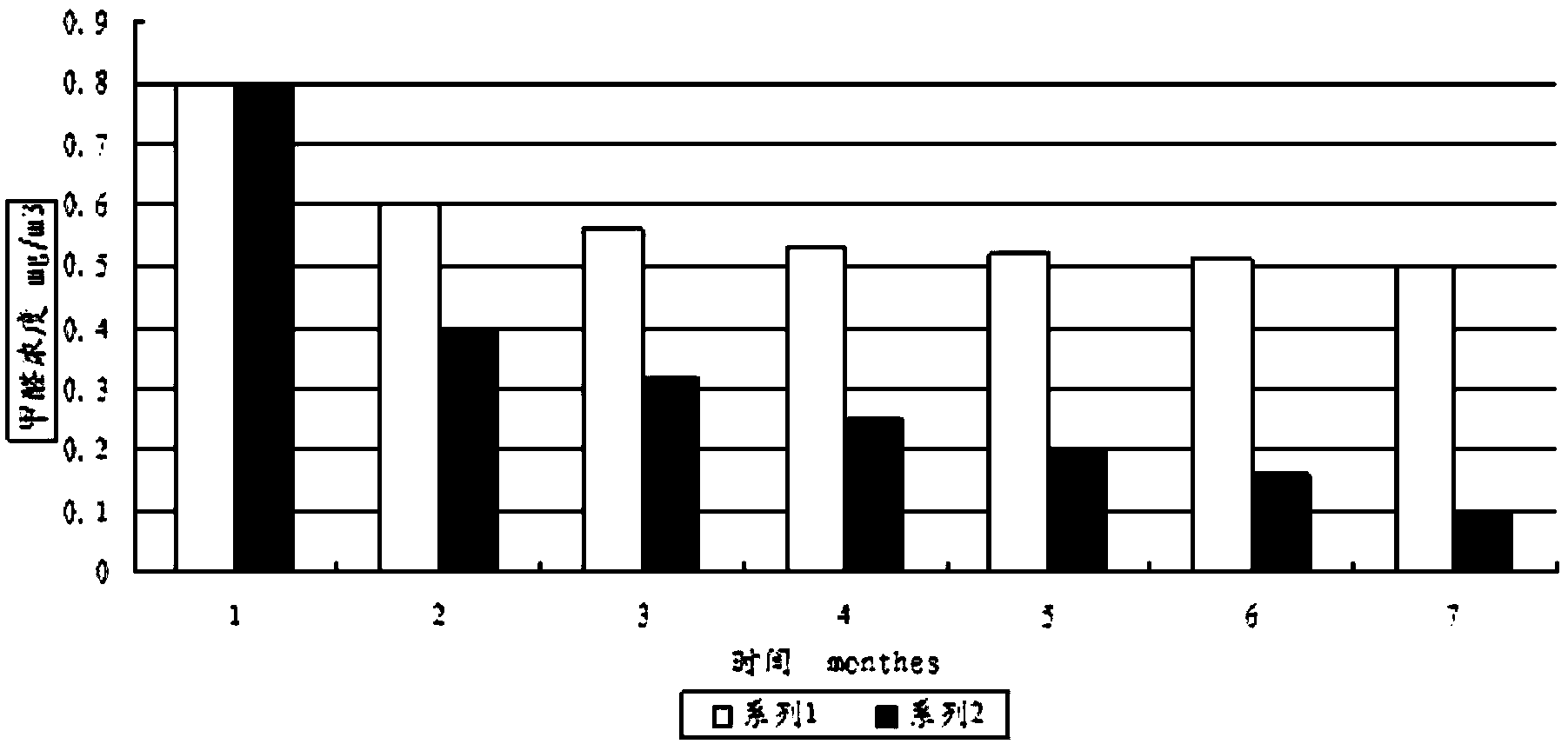

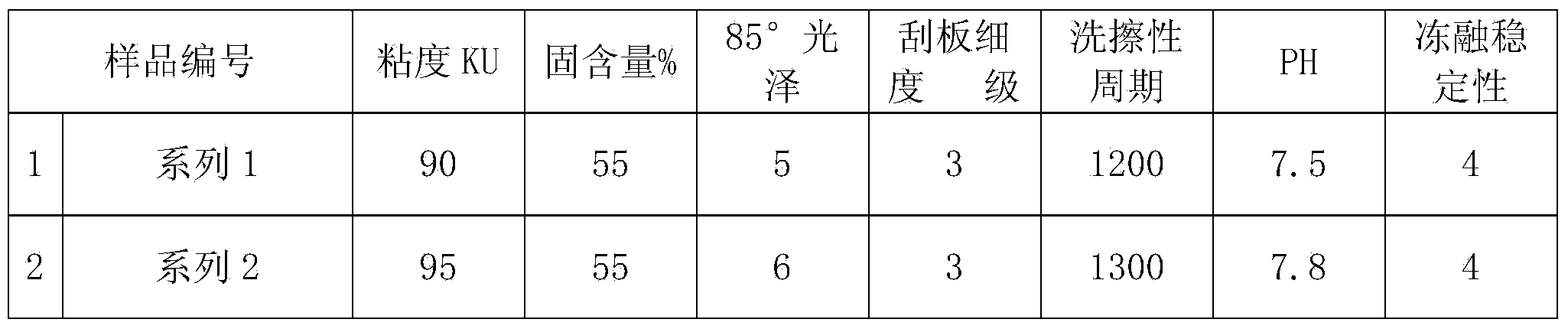

[0038] The coating (series 2) prepared by the modified talc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com