Water-based environment-friendly modified alkyd wood paint

An environmentally friendly and modified technology, applied in coatings and other directions, can solve the problems of complicated and expensive solvent removal process, poor wood permeability, etc., and achieve the effect of high utilization rate of biological resources, strong permeability, and full coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

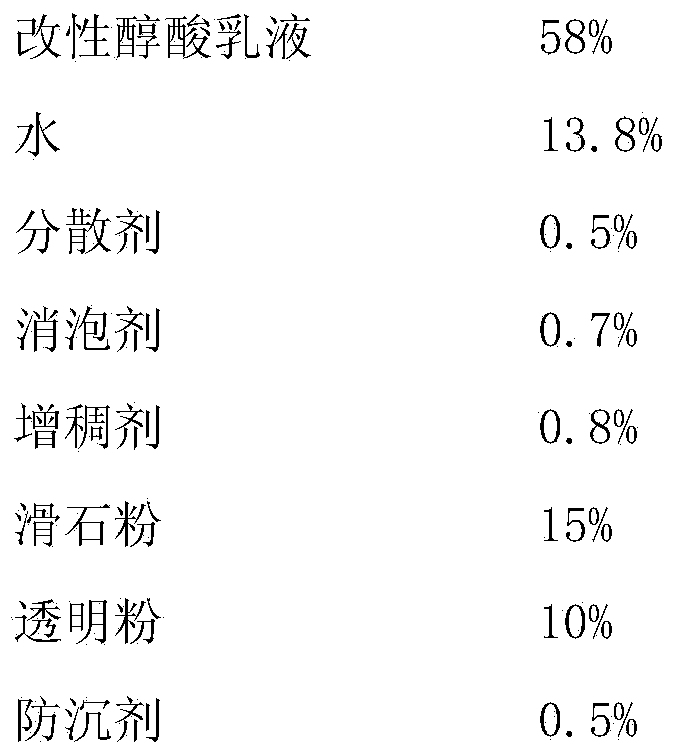

[0035] Each component is weighed according to the following weight percentage:

[0036]

[0037] The above-mentioned dispersant uses Dispers 750W from German Tego Company; the defoamer adopts Foamex 810 and Foamex 800 from German Tego Company; the thickener adopts ACRYSOL RM-5000 from American ROHM&HAAS Company; the anti-sedimentation agent adopts BYK-420 from German BYK Company; The wetting agent is Wet270 from Tego Company of Germany; the pH regulator is 2-amino-2-methyl-1-propanol and AMP-95 from DOW Company of the United States is used.

[0038] The preparation method is as follows:

[0039] Prepare raw materials according to the set weight percentage, put part of water (6% by weight), dispersant and defoamer Foamex 810 into the multi-purpose disperser and stir at high speed, add thickener at the same time, after complete dispersion, add talcum powder , transparent powder and anti-sedimentation agent, high-speed dispersion evenly (speed 1500 rpm). Transfer to a sand m...

Embodiment 2

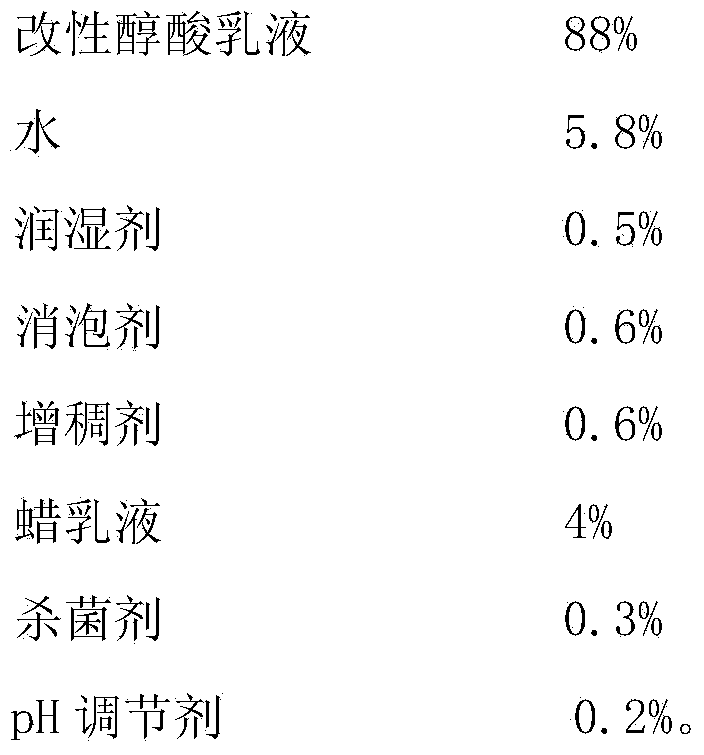

[0043] Each component is weighed according to the following weight percentage:

[0044]

[0045] The above-mentioned wetting agent adopts Wet270 from Tego Company of Germany; the defoamer adopts Foamex 825 from Tego Company of Germany; the thickener adopts ACRYSOL RM-5000 from ROHM & HAAS Company of the United States; the wax emulsion adopts AQUACER515 from BYK Company of Germany; the bactericide is isothiazoline The ketone was Kathon LXE from ROHM & HAAS Company of the United States; the pH regulator was 2-amino-2-methyl-1-propanol and AMP-95 from DOW Company of the United States was used.

[0046] The preparation method is as follows:

[0047] Prepare the raw materials according to the set mass percentage, put the modified alkyd emulsion, wetting agent, defoamer, thickener, wax emulsion, bactericide and water into the multi-purpose disperser, and stir evenly at a slow speed (speed 500 rpm / points), adjust the pH value of the system to 8 with AMP-95 to obtain the finished...

Embodiment 3

[0052] Each component is weighed according to the following weight percentage:

[0053]

[0054] The above-mentioned dispersant uses Dispers 750W from Tego Company of Germany; the defoamer adopts Foamex 810 and Foamex 800 from Tego Company of Germany; the thickener adopts ACRYSOL RM-5000 from ROHM&HAAS Company of the United States; the titanium dioxide adopts DuPont Ti-Puer R-706 from the United States; The anti-sedimentation agent is BYK-420 from BYK Company of Germany; the wetting agent is Wet270 from Tego Company of Germany; the wax emulsion is AQUACER515 from BYK Company of Germany; the pH regulator is 2-amino-2-methyl-1-propanol, using AMP-95 of American DOW company.

[0055] The preparation method is as follows:

[0056] Prepare raw materials according to the set mass percentage, put part of water (5% by weight), dispersant, and defoamer Foamex810 into a multi-purpose disperser for high-speed stirring, and add a thickener at the same time. After complete dispersion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com