Relative laser shock strength characterization method

A technology of laser shock and strength, which is applied in the direction of material analysis, force/torque/power measuring instrument, measuring device, etc. by optical means, can solve the problem of long detection time of residual stress size and residual stress depth distribution, limited development and application, Expensive experiments and other problems, to achieve the effect of simple principle, low process cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

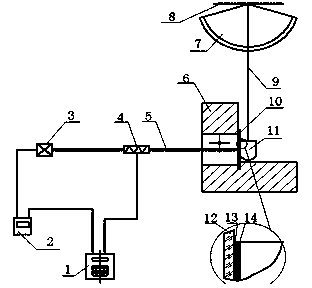

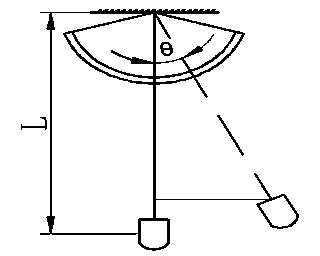

[0029] Select a target with a mass of 5g, the material is 45 steel, and the length of the cycloid is 750mm. The experiment uses a single-pulse neodymium glass laser with a wavelength of 1.06μm, a pulse width of 20ns, and a laser energy of 27.5J. The side of the target is coated with There is 0.1mm black paint (14), apply a small amount of glycerin (13) on the black paint, attach the constraining layer (12) to the side, choose K9 glass for the constraining layer (12), and position and support it through the positioning support frame (6) , the target (11) is in critical contact with the support frame, adjust the laser parameters, the impact path and the position of the pendulum support to ensure that the laser impact point coincides with the center of gravity of the target. After all the preparatory conditions are completed, the central processing unit (1) issues an instruction to make the laser (3) emit a pulsed laser beam through the laser controller (2), and the laser beam pas...

example 2

[0031] Select two targets of different materials, namely: metal target (aluminum alloy) and non-metal target (PVC), the length of the cycloid is 750mm, and the laser shock parameters are the same as in Example 1, that is, the single-pulse neodymium glass is used The laser has a wavelength of 1.06 μm, a pulse width of 20 ns, and a laser energy of 27.5 J. The thickness of the black paint coating on the target is 0.1 mm. The constrained layer K9 glass is the same size and specification as Example 1, and the external conditions are guaranteed to be the same. The central processing unit (1) issues instructions, and the laser controller (2) causes the laser (3) to emit pulsed laser beams to impact each target respectively. The corresponding impulse P of the aluminum alloy is calculated with the same measurement method as in Example 1. 铝 =4.125×10 -3 N.S, PVC target corresponding impulse P PVI =5.775×10 -3 N.S.

[0032] Select 45 steel as the standard target, compare the impact st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser pulse width | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com