Zinc oxide/polypyrrole nano composite resistance-type film gas sensor and production method thereof

A gas sensor and pyrrole nanotechnology, applied in the direction of material resistance, can solve the problems of unsuitable batch preparation, etc., and achieve the effect of promoting response sensitivity, promoting synergistic effect, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

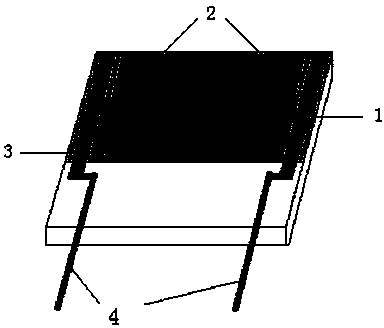

[0027] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use. The interdigitated gold electrodes are 5 pairs, the interdigitated gold electrodes have a fork width of 200 μm, and an interdigital gap of 200 μm ;

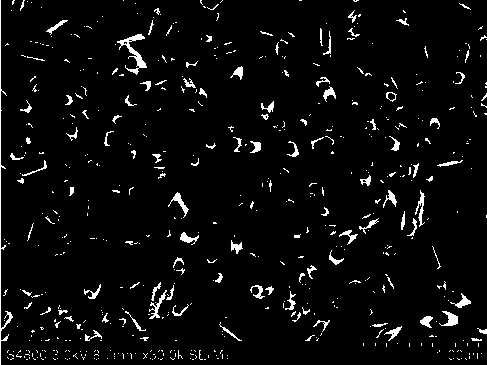

[0028] (2) In step (1), the surface of the interdigitated gold electrode with a ceramic substrate is coated with a zinc oxide nanocolloid solution with a concentration of 0.1 mol / liter. The solvent of the zinc oxide nanocolloid solution is ethanol, and the diameter of the zinc oxide particle is 75 nanometers, heated at 100°C for 2 h, with the surface of the interdigitated gold electrode facing down, horizontally immerse in the aqueous solution of zinc nitrate and hexamethylenetetramine, the concentration of zinc nitrate in the aqueous solution is 0.025 mol / L, hexamethylene The concentration of tetramine is 0.025 mol / liter, reacted at 90°C for 4 hours, then fully washed with deionized wat...

Embodiment 2

[0034] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use. The interdigitated gold electrodes are 5 pairs, the interdigitated gold electrodes have a fork width of 200 μm, and an interdigital gap of 200 μm ;

[0035] (2) In the step (1), the surface of the interdigitated gold electrode with a ceramic substrate is coated with a zinc oxide nanocolloid solution with a concentration of 0.4 mol / liter, and the solvent of the zinc oxide nanocolloid solution is N,N-dimethyl formazan Amide, the diameter of zinc oxide particles is 125 nanometers, heated at 100 ° C for 2 h, with the surface of the interdigitated gold electrode facing down, and horizontally immersed in an aqueous solution of zinc nitrate and hexamethylenetetramine, the concentration of zinc nitrate in the aqueous solution is 0.025 mol / L, the concentration of hexamethylenetetramine is 0.025 mol / L, react at 90°C for 4 hours, then fully wash...

Embodiment 3

[0038] (1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use. The interdigitated gold electrodes are 20 pairs, the interdigitated gold electrodes have a fork width of 20 μm, and an interdigital gap of 20 μm ;

[0039] (2) In step (1), the surface of the interdigitated gold electrode with a ceramic substrate is coated with a zinc oxide nanocolloid solution with a concentration of 0.05 mol / liter. The solvent of the zinc oxide nanocolloid solution is ethanol, and the diameter of the zinc oxide particle is 10 nanometers, heated at 230°C for 2 h, with the surface of the interdigitated gold electrode facing down, horizontally immerse in an aqueous solution of zinc nitrate and hexamethylenetetramine, the concentration of zinc nitrate in the aqueous solution is 0.02 mol / L, hexamethylene The concentration of tetraamine is 0.02 mol / liter, reacted at 100°C for 4 hours, then fully washed with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com