Preparation method of graphene-modified activated carbon for supercapacitor

A supercapacitor and graphene modification technology, which is applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problem that the performance of capacitors cannot be greatly improved, the heat dissipation performance of supercapacitors is not ideal, and the pore size distribution is not good. Reasonable and other issues, to achieve the effect of low comprehensive use cost, improved heat dissipation performance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

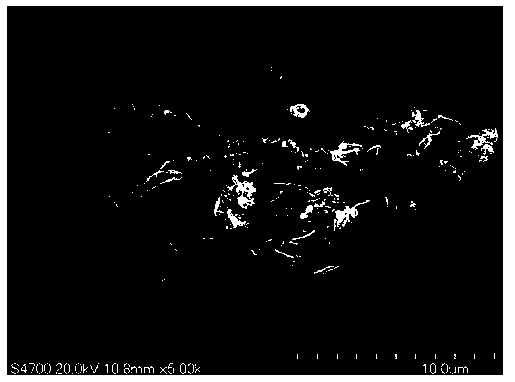

Image

Examples

Embodiment 1

[0023] A preparation method of activated carbon for graphene oxide modified supercapacitor is to wash 900-mesh fruit shell activated carbon with deionized water twice, add graphene oxide aqueous dispersion, ultrasonically treat for 0.5h, heat to 60°C, and stir at constant temperature 0.5h, then add ammonia water and hydroxylamine hydrochloride mixed solution for reduction, and finally filter the reaction system and dry for 1h to obtain the activated carbon for graphene oxide modified supercapacitor in this embodiment; wherein, fruit shell activated carbon and graphite oxide The mass ratio of olefin aqueous dispersion is 1:1, and the molar mass ratio of ammoniacal liquor and hydroxylamine hydrochloride is 1:2, and the mass ratio of graphene oxide and hydroxylamine hydrochloride is 1:0.5, and graphene oxide aqueous dispersion is graphene oxide and The mass ratio of deionized water is a mixture of 1‰, and the sheet diameter of graphene oxide is 90nm.

Embodiment 2

[0025] A preparation method of activated carbon for graphene oxide modified supercapacitor is to wash 10000 mesh woody activated carbon with deionized water for 5 times, add graphene oxide aqueous dispersion, ultrasonically treat for 10 hours, heat to 100°C, and stir at constant temperature for 10 hours, Then add ammonia water and hydroxylamine hydrochloride mixed solution for reduction, and finally filter and dry the reaction system for 16 hours to obtain the activated carbon for the graphene oxide modified supercapacitor of this embodiment; wherein, woody activated carbon and graphene oxide water dispersion The mass ratio of ammonia water and hydroxylamine hydrochloride is 1:100, the molar mass ratio of ammonia water and hydroxylamine hydrochloride is 5:1, the mass ratio of graphene oxide and hydroxylamine hydrochloride is 1:5, and the graphene oxide aqueous dispersion is the mixture of graphene oxide and deionized water. With a mass ratio of 20% of the mixture, the graphene ...

Embodiment 3

[0027] A preparation method of activated carbon for graphene oxide modified supercapacitors is to wash 1000 mesh straw activated carbon with deionized water for 4 times, add graphene oxide aqueous dispersion, ultrasonically treat for 2 hours, heat to 90°C, and stir at constant temperature for 5 hours. Then add ammonia water and hydroxylamine hydrochloride mixed solution for reduction, and finally filter and dry the reaction system for 20 hours to obtain the activated carbon for graphene oxide modified supercapacitor in this embodiment; wherein, straw activated carbon and graphene oxide aqueous dispersion The mass ratio of ammonia water and hydroxylamine hydrochloride is 1:30, the molar mass ratio of ammonia water and hydroxylamine hydrochloride is 2:1, the mass ratio of graphene oxide and hydroxylamine hydrochloride is 1:1, and the graphene oxide aqueous dispersion is the mixture of graphene oxide and deionized water. The mass ratio of the mixture is 3%, and the sheet diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com