Circulating cooling method and apparatus used for roasting aluminum oxide

A circulating cooling and alumina technology, which is applied in the field of alumina, can solve the problems of water consumption and heat loss, increase the investment of circulating water station projects, etc., and achieve the effects of reducing energy consumption, reducing pollution and water consumption, and facilitating operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

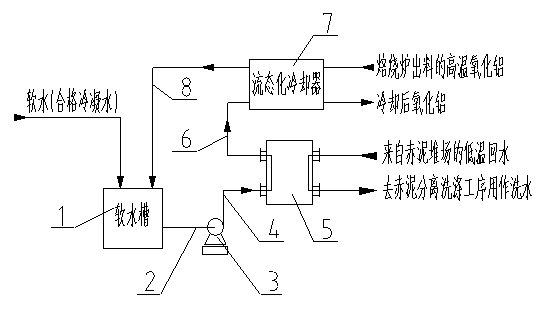

[0013] The present invention will be further described below in conjunction with accompanying drawing. As shown in the accompanying drawings, the circulating cooling method of roasted alumina of the present invention is to send the qualified condensed water from the evaporation of mother liquor or pressure boiling and dissolution process to the softening water tank 1, and use the softening water pump 3 to pass through the pipeline 2 and the pipeline 4 in the softening water tank. The soft water is pumped to the plate heat exchanger 5 for heat exchange with the low-temperature return water from the red mud stockyard. The demineralized water is sent to the fluidized cooler 7 through the pipeline 6 as cooling water, and conducts indirect heat exchange with the high-temperature discharged alumina. The high-temperature soft water exchanges heat indirectly with the low-temperature return water from the red mud stockpile. The cooled soft water is used to cool high-temperature alumina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com