Enhanced HEMT (high electron mobility transistor) device with back field plate structure and preparation method thereof

An enhanced, plate-structured technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in releasing electrons, discounting, etc., and achieve the effect of increasing breakdown voltage and suppressing the effect of current collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

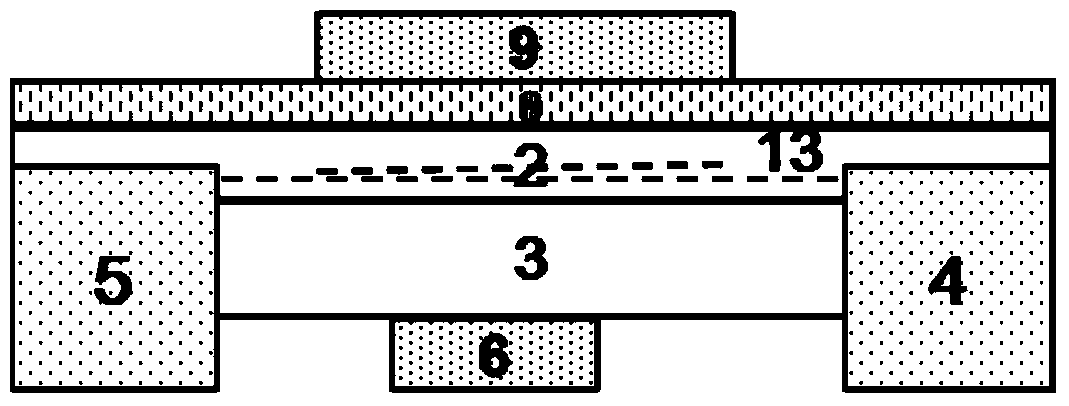

[0056] Example 1 refer to image 3 , the enhanced HEMT has AlGaN / GaN. GaN is not intentionally doped. AlGaN can be doped with n-type impurities or not. The thickness of AlGaN is about 15 to 30 nm.

[0057] The enhancement mode HEMT has a drain 4 and a source 5 . The drain 4 and the source 5 form an ohmic contact with AlGaN / GaN, and form a good electrical connection with the two-dimensional electron gas in the channel. The drain electrode 4 and the source electrode 5 are ohmic contacts formed by rapid high-temperature annealing of multilayer metals (such as Ti / Al / Ti / Au or Ti / Al / Ni / Au, etc.).

[0058] Further, the enhanced HEMT has a gate 6, between the source 5 and the drain 4, the distance close to the source 5 is relatively short, and the gate 6 is located on AlGaN.

[0059] The back field plate electrode 9 is located on the GaN, overlaps the gate 6 in the vertical direction, and extends to the source 5 and the drain 4 (or only extends to the drain 4 or the source 5, ...

Embodiment 2

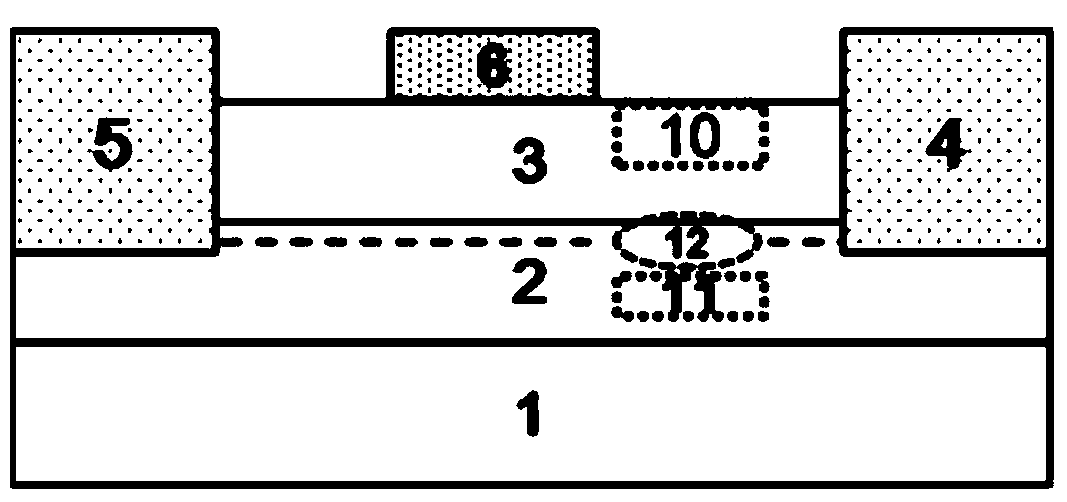

[0065] Example 2 refer to Figure 6 , the enhanced HEMT has AlGaN / GaN. GaN is not intentionally doped. AlGaN can be doped with n-type impurities or not. The thickness of AlGaN is about 15 to 30 nm.

[0066] The enhancement mode HEMT has a drain 4 and a source 5 . The drain 4 and the source 5 form an ohmic contact with AlGaN / GaN, and form a good electrical connection with the two-dimensional electron gas in the channel. The drain electrode 4 and the source electrode 5 are ohmic contacts formed by rapid high-temperature annealing of multilayer metals (such as Ti / Al / Ti / Au or Ti / Al / Ni / Au, etc.).

[0067] Further, the enhanced HEMT has a gate 6, between the source 5 and the drain 4, the distance close to the source 5 is relatively short, and the gate 6 is located on AlGaN.

[0068] The back field plate electrode 9 is located on the GaN, overlaps the gate 6 in the vertical direction, and extends to the source 5 and the drain 4 (or only extends to the drain 4 or the source 5, ...

Embodiment 3

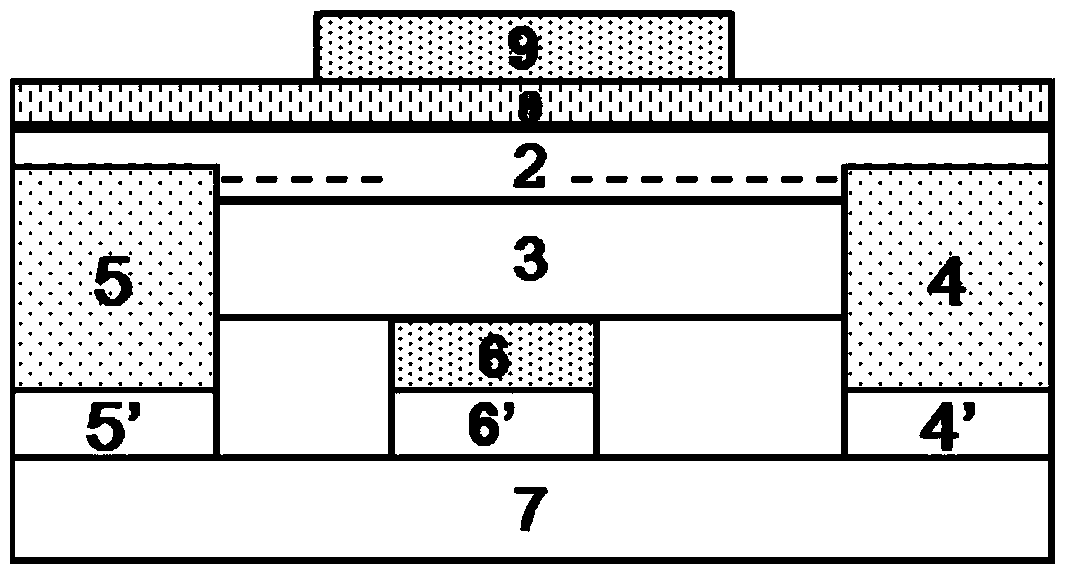

[0074] Example 3 refer to Figure 7 , the enhanced HEMT has AlGaN / GaN. GaN is not intentionally doped. AlGaN can be doped with n-type impurities or not. The thickness of AlGaN is about 15 to 30 nm.

[0075] The enhancement mode HEMT has a drain 4 and a source 5 . The drain 4 and the source 5 form an ohmic contact with AlGaN / GaN, and form a good electrical connection with the two-dimensional electron gas in the channel. The drain electrode 4 and the source electrode 5 are ohmic contacts formed by rapid high-temperature annealing of multilayer metals (such as Ti / Al / Ti / Au or Ti / Al / Ni / Au, etc.).

[0076] Further, the enhanced HEMT has a gate 6, between the source 5 and the drain 4, the distance close to the source 5 is relatively short, and the gate 6 is located on AlGaN.

[0077] The back field plate electrode 9 is located on the GaN, overlaps the gate 6 in the vertical direction, and extends toward the source 5 and the drain 4 respectively.

[0078] Wherein, an insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com