Calcium titanate/calcium oxide composite photocatalyst as well as preparation method and application thereof

A technology of calcium oxide and calcium titanate, applied in the field of photocatalysis, can solve the problem of low photocatalytic activity, achieve high photocatalytic activity, simple preparation process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolve 0.0491mol of butyl titanate in 80ml of absolute ethanol, sonicate for 1 hour and then stand for 12 hours;

[0042] (2) Add 0.0491mol calcium nitrate tetrahydrate solid to 80ml 95% ethanol solution, heat and stir at 60℃ to fully dissolve it, then add 15ml glacial acetic acid and stir well for 0.5h;

[0043] (3) Under full stirring, add the solution obtained in step (2) dropwise to the solution obtained in step (1), and continue to stir for 1 hour, where the molar ratio of calcium to titanium is 1:1;

[0044] (4) Aging the solution obtained in step (3) at room temperature for 24 hours;

[0045] (5) Put the obtained light yellow transparent gel in an oven and dry at 60°C to obtain a light yellow solid;

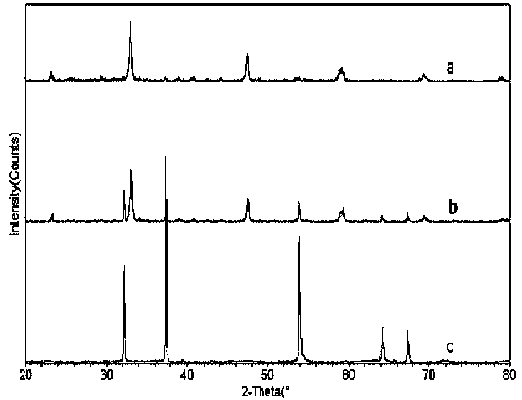

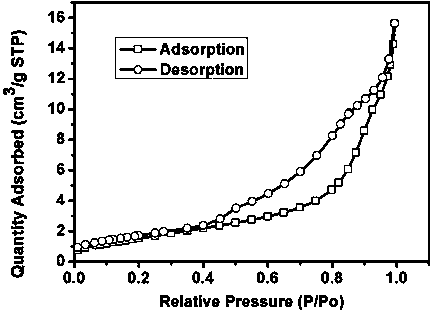

[0046] (6) Put the dry light yellow solid into a muffle furnace at 500°C and calcinate for 2h at a heating rate of 1°C / min. The white powder obtained is a calcium titanate / calcium oxide composite photocatalyst.

[0047] Add 10 mg of calcium titanate / calcium oxide com...

Embodiment 2

[0049] (1) Dissolve 0.0491mol of tetraisopropyl titanate in 80ml of absolute ethanol, sonicate for 1h and then stand for 12h;

[0050] (2) Add 0.0491mol calcium nitrate tetrahydrate solid to 80ml 95% ethanol solution, heat and stir at 60°C to fully dissolve it, then add 15ml glacial acetic acid and stir well for 0.5h;

[0051] (3) Under sufficient stirring, add the solution obtained in step (2) dropwise to the solution obtained in step (1), and continue to stir for 1 hour, where the molar ratio of calcium to titanium is 1:1;

[0052] (4) Aging the solution obtained in step (3) at room temperature for 24 hours;

[0053] (5) Put the obtained light yellow transparent gel in an oven and dry at 60°C to obtain a light yellow solid;

[0054] (6) Put the dry light yellow solid in a muffle furnace at 700°C for 2h, and the heating rate is 1°C / min. The white powder obtained is the calcium titanate / calcium oxide composite photocatalyst.

[0055] Add 2 mg of calcium titanate / calcium oxide composite p...

Embodiment 3

[0057] (1) Dissolve 0.0491 mol of butyl titanate in 80 ml of absolute ethanol, sonicate for 1 hour and then stand for 12 hours;

[0058] (2) Add 0.0491mol calcium chloride dihydrate solid to 80ml 95% ethanol solution, heat and stir at 60℃ to fully dissolve it, then add 15ml glacial acetic acid and stir well for 0.5h;

[0059] (3) Under full stirring, add the solution obtained in step (2) dropwise to the solution obtained in step (1), and continue to stir for 1 hour, where the molar ratio of calcium to titanium is 1:1;

[0060] (4) Aging the solution obtained in step (3) at room temperature for 24 hours;

[0061] (5) Put the obtained light yellow transparent gel in an oven and dry at 60°C to obtain a light yellow solid;

[0062] (6) Put the dry light yellow solid into a muffle furnace at 600°C and calcinate for 4h at a heating rate of 1°C / min. The white powder obtained is a calcium titanate / calcium oxide composite photocatalyst.

[0063] Add 2 mg of calcium titanate / calcium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com