Gas guide type anaerobic reactor

A technology of anaerobic reactor and anaerobic reaction tank, applied in the field of anaerobic reactor, can solve the problems of high operating cost and investment cost, too many reaction levels, and high design requirements, and achieves convenient operation, good market prospect, Manufacture simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

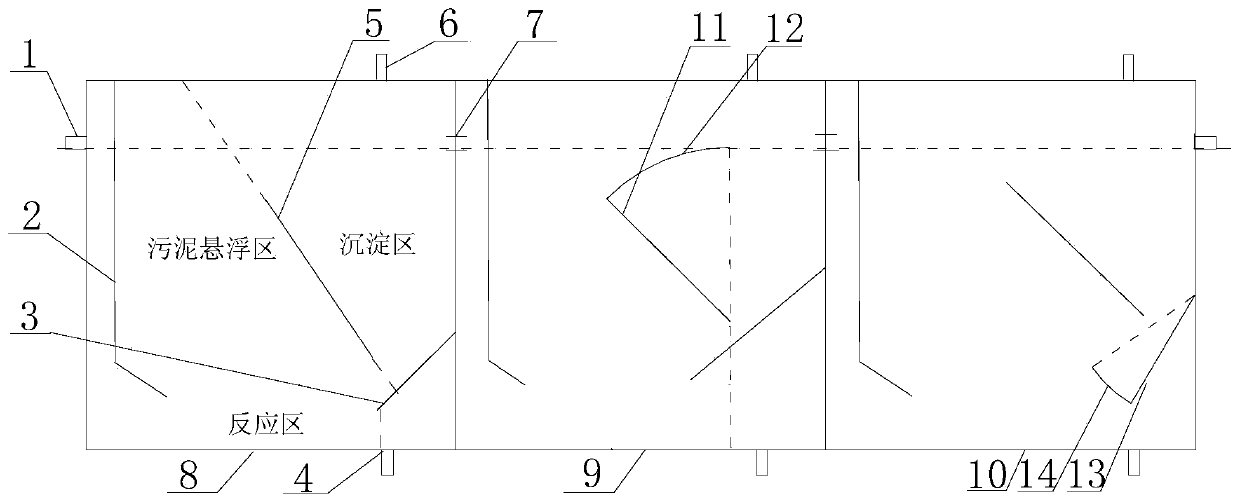

[0034] A multi-stage anaerobic reactor with gas diversion, its structure is as figure 1 As shown, it can be one anaerobic reaction tank, or multiple anaerobic reaction tanks connected in series. As shown in this embodiment, a primary anaerobic reaction tank 8 and a secondary anaerobic reaction tank 9 are provided until they are connected in series to n Grade anaerobic reaction tank 10. The reaction tanks are connected by welding. The upper part of each reaction tank is provided with an exhaust port 6, the bottom of the side is provided with a slag discharge port 4, and the first-level anaerobic reaction tank 8 is provided with a water inlet 1 from left to right. The water inlet 1 is at the upper end of the left side wall of the reaction tank. Waste water enters the reaction zone through the feed plate 2 and enters the sludge suspension area formed by the feed plate 2 and the deflector 5 under the action of the generated biogas. The angle between the plate 5 and the filling cov...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is that the angle between the deflector 5 and the tank cover is 60°, the angle between the sludge plate and the right wall of the reaction tank is 30°, and the extension line from the deflector to the sludge plate The length of the sludge plate is about 1 / 10 of the length of the deflector, the distance from the bottom of the sludge plate to the bottom of the reaction tank is about 1 / 10 of the height of the reactor, and the length of the sludge plate protruding from the deflector is about the length of the sludge plate The ratio of the volume of the sludge suspension area to the volume of the sedimentation area is about 2:1. The embodiment of the present invention is applied to some aquaculture wastewater treatment in Hunan, and the water quality after being treated by a multi-stage anaerobic generator with gas diversion of the present invention: COD is 186mg / L, which is lower than the nationally allowed aquaculture p...

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is that the angle between the deflector 5 and the tank cover is 90°, the angle between the sludge plate and the right wall of the reaction tank is 30°, and the extension line from the deflector to the sludge plate The length of the sludge plate is about 1 / 10 of the length of the deflector, the distance from the bottom of the sludge plate to the bottom of the reaction tank is about 1 / 5 of the height of the reactor, and the length of the sludge plate protruding from the deflector is about the length of the sludge plate The ratio of the volume of the sludge suspension area to the volume of the sedimentation area is about 2:1. The embodiment of the present invention is applied to some aquaculture wastewater treatment in Hunan, and the water quality after treatment by a multi-stage anaerobic generator with gas diversion of the present invention: COD is 220 mg / L, which is lower than the nationally allowed aquaculture pollu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com