Preparation method of bionic erosion-resisting composite material enhanced phase based on rose willow

A composite material and anti-erosion technology, applied in ceramic products, applications, medical science, etc., can solve the problems of mineral consumption, energy, environmental pollution, etc., and achieve the effect of enhancing erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

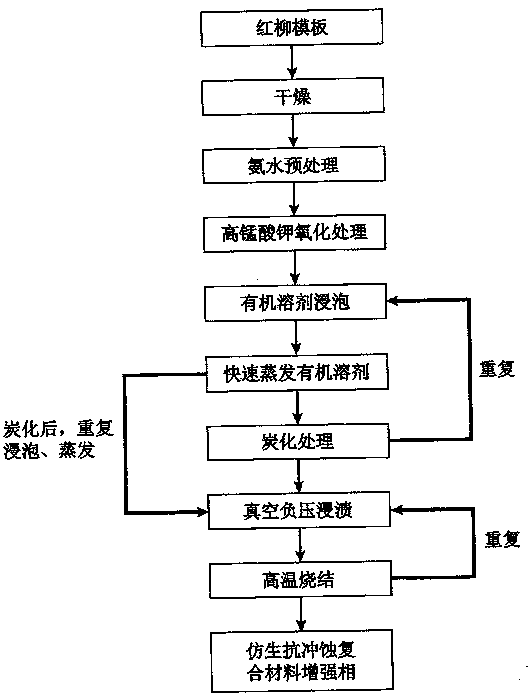

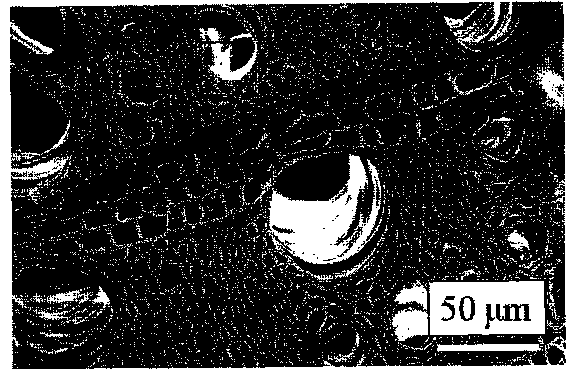

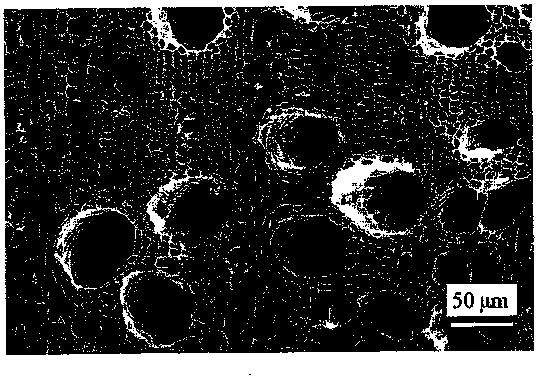

[0025] see figure 1 , figure 2 , image 3 and Figure 4 as shown,

[0026] Step 1: Select tamarisk growing in saline-alkali land, which contains a large amount of calcium oxalate, calcium carbonate and other components, and has a porous structure for pretreatment. The specific method is: cut tamarisk into 20×10×3mm 3 The block was first boiled in 5% ammonia water at 100°C for 8 hours to carry out extraction pretreatment, then washed with deionized water, and dried in an oven at 80°C for 24 hours.

[0027] Step 2: soak the red willow obtained in step 1 with 0.5% potassium permanganate solution for 1 hour, wash with deionized water, and dry in a drying oven at 80° C. for 24 hours.

[0028] Step 3: soak the tamarisk obtained in step 2 with alcohol for 24 hours, and dry in a drying oven at 80° C. for 1 hour to quickly evaporate the alcohol. Repeat this step 5 times.

[0029] Step 4: raise the temperature of the vacuum furnace to 200° C., and then increase the temperature by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com