Production method of cyclohexyl acetate and used reaction rectifying tower

A technology of cyclohexyl acetate and a reactive distillation column, which is applied in the field of preparation of cyclohexyl acetate, can solve the problems of low conversion rate of cyclohexene, slow reaction speed, and inability to fully meet production needs, so as to improve conversion rate and reduce Energy consumption, the effect of reducing equipment investment costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

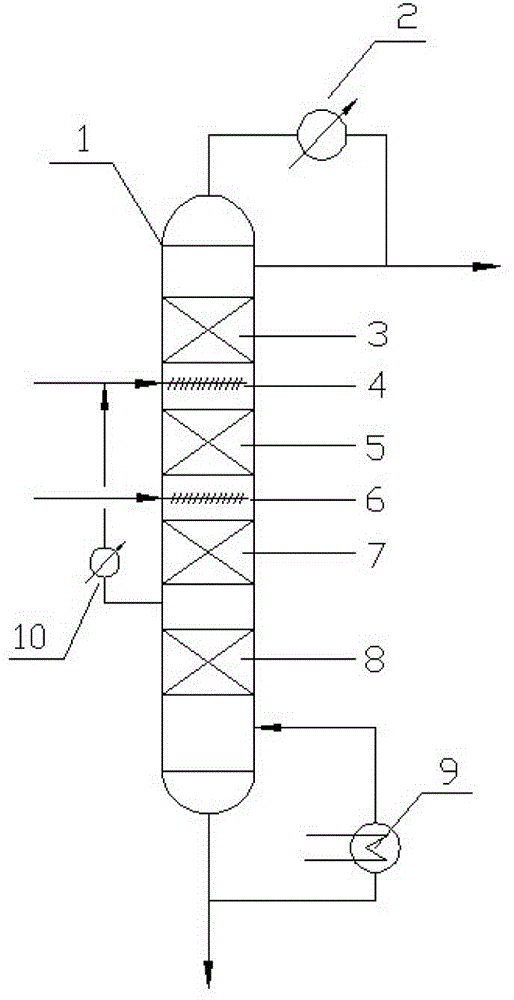

Image

Examples

Embodiment 1

[0022] The following examples are tests carried out to the present invention under laboratory conditions. The filler is a 4mm metal θ ring, the height of the packing layer in the upper rectifying section is 0.3m, and the height of the packing layer in the lower rectifying section is 0.5m. Of course, the present invention is not limited to the following examples, and changes, modifications, additions or replacements made by those skilled in the art within the essential scope of this patent also belong to the protection scope of this patent.

[0023] Example 1

[0024] Using a sulfonic acid-based ion exchange resin as a catalyst, the feed rate of acetic acid is 1.3kg / h, the feed temperature is 83°C, and the feed pressure is 101kPa. The mixed gas after benzene hydrogenation reaction (mass fraction: cyclohexene 0.341, benzene 0.412, cyclohexane 0.247) The feed rate is 2.465kg / h, the feed temperature is 83°C, the feed pressure is 101kPa, and the cyclohexene and acetic acid are coun...

Embodiment 2

[0026] Using a sulfonic acid-based ion exchange resin as a catalyst, the feed rate of acetic acid is 1.3kg / h, the feed temperature is 83°C, and the feed pressure is 101kPa. The mixed gas after benzene hydrogenation reaction (mass fraction: cyclohexene 0.341, benzene 0.412, cyclohexane 0.247) The feed rate is 2.465kg / h, the feed temperature is 83°C, the feed pressure is 101kPa, and the cyclohexene and acetic acid are countercurrently contacted and reacted on the surface of the solid catalyst. The reactive distillation column is operated under normal pressure, the reflux ratio R=0.64, and the circulation volume of side line extraction is 0.642kg / h. The output of liquid at the bottom of the tower is 1.347kg / h, the molar fraction of cyclohexyl acetate is 0.9411, the molar fraction of acetic acid is 0.0589, and hardly contains benzene, cyclohexane and cyclohexene; the output of the tower top is 2.418kg / h, and the The molar fraction of hexene was 0.0303, the molar fraction of acetic...

Embodiment 3

[0028] Using a sulfonic acid-based ion exchange resin as a catalyst, the feed rate of acetic acid is 1.3kg / h, the feed temperature is 83°C, and the feed pressure is 101kPa. The mixed gas after benzene hydrogenation reaction (mass fraction: cyclohexene 0.341, benzene 0.412, cyclohexane 0.247) The feed rate is 2.465kg / h, the feed temperature is 83°C, the feed pressure is 101kPa, and the cyclohexene and acetic acid are countercurrently contacted and reacted on the surface of the solid catalyst. The reactive distillation column is operated under normal pressure, the reflux ratio R=0.64, and the circulation volume of the side line is 1.22kg / h. The output of liquid at the bottom of the tower is 1.203kg / h, the molar fraction of cyclohexyl acetate is 0.9957, the molar fraction of acetic acid is 0.0043, and hardly contains benzene, cyclohexane and cyclohexene; the output of the tower top is 2.562kg / h, and the cyclohexyl acetate The molar fraction of hexene is 0.0267, the molar fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com