High-performance low-gloss exterior wall texture coating and preparation method thereof

A texture coating and low-gloss technology, applied in lignin coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of whitening performance, texture coating fading, low gloss, etc., and achieve excellent environmental protection, anti-corrosion Reduced cracking performance and excellent yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

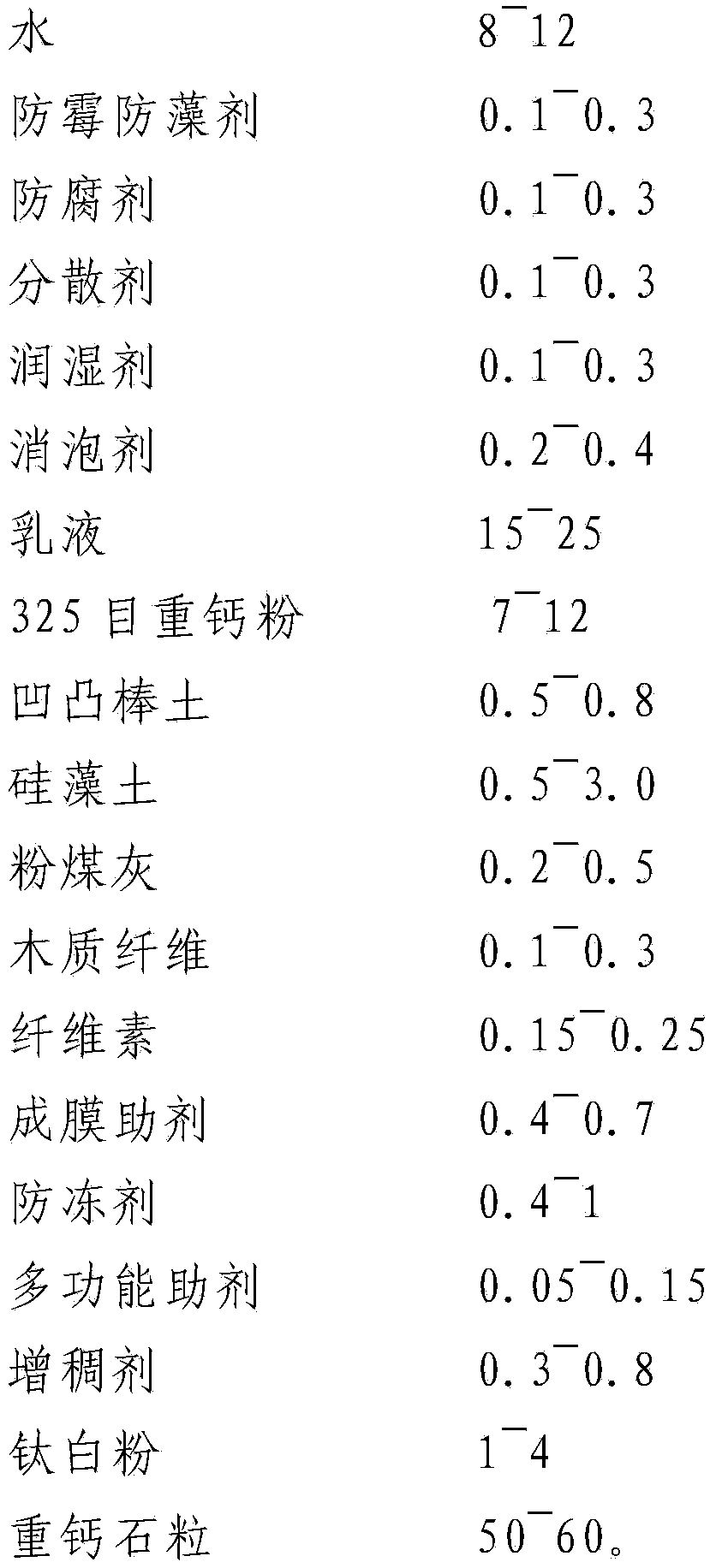

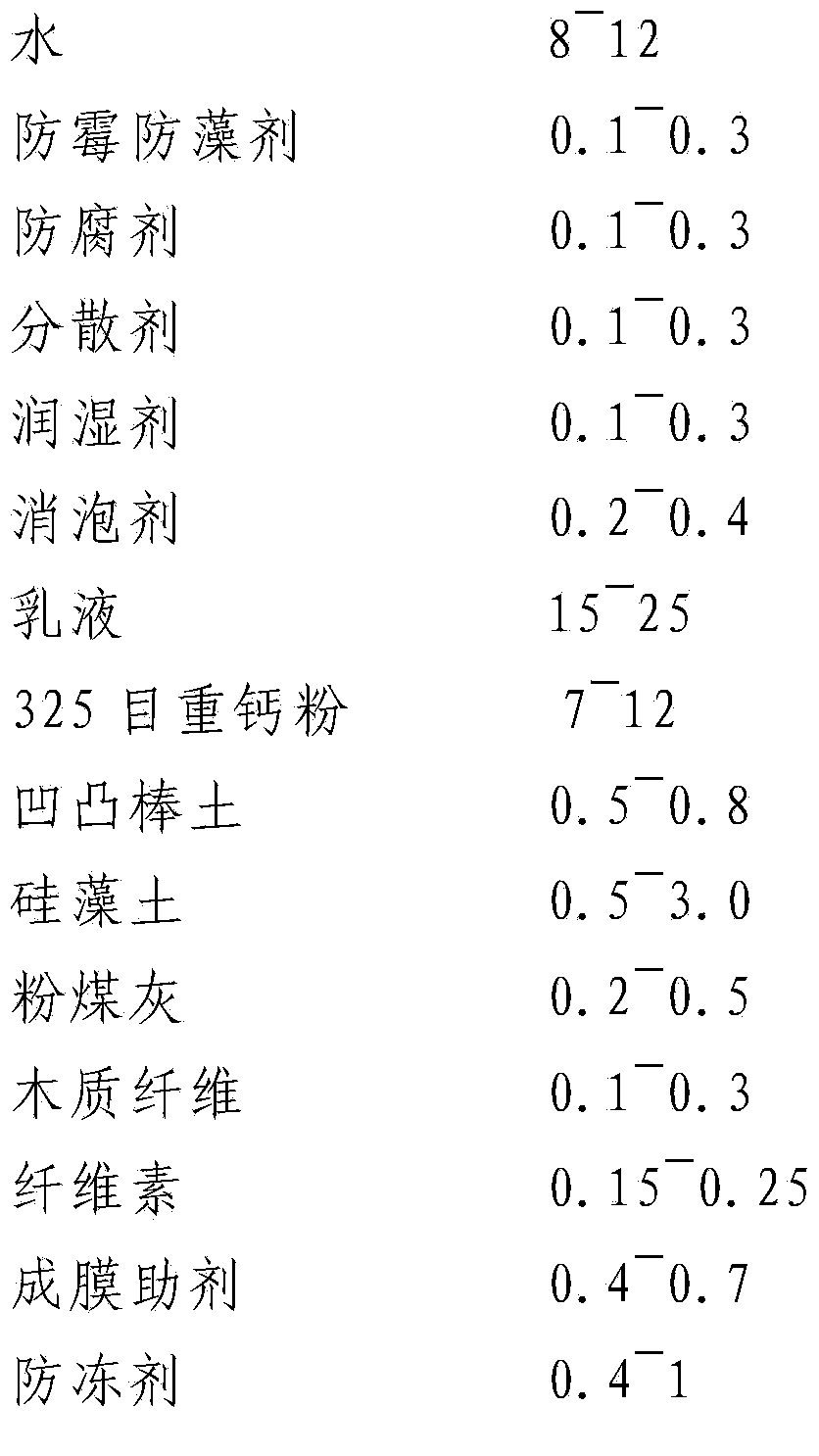

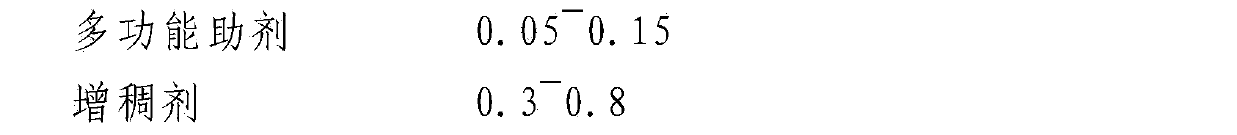

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 is to only carry out matting with 325 purpose heavy calcium powders, and the effect is very unsatisfactory.

Embodiment 2

[0050] In Example 2, the addition of the emulsion is reduced to 12%, but the gloss is still unsatisfactory, indicating that the matte effect can only be achieved when the emulsion is reduced to below 12%, and the other properties of the product will obviously decline like this, so the present invention does not use This traditional method.

Embodiment 3

[0051] In Example 3 and Example 4, diatomaceous earth and fly ash were added respectively to deluster, and the gloss decreased significantly. In Example 5 and Example 6, diatomaceous earth and fly ash were mixed to deluster, and the gloss further decreased, indicating that silicon Alginate and fly ash are good matting fillers. When the gloss of the mother liquor is controlled below 2.4, the gloss of the final product is dull.

[0052] From embodiment 6, embodiment 7, embodiment 8 comparative view, after adding wetting agent and multifunctional auxiliary agent, the antifreeze of product has had obvious promotion, illustrates that wetting agent and multifunctional auxiliary agent have great influence on emulsion colloid. The granules play a protective role to prevent the emulsion from being squeezed by the crystal. If the formula does not use a wetting agent, in order to achieve antifreeze performance, the amount of antifreeze must be increased, which will increase the VOC of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com