High-strength high-temperature resistant anti-cracking elastic waterproof coating and preparation method thereof

A waterproof coating and high-temperature-resistant technology, applied in epoxy resin coatings, coatings, etc., can solve problems such as fire hazards, waterproof layer failure construction, internal stress imbalance of paint films, etc., to prolong service life and improve high temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

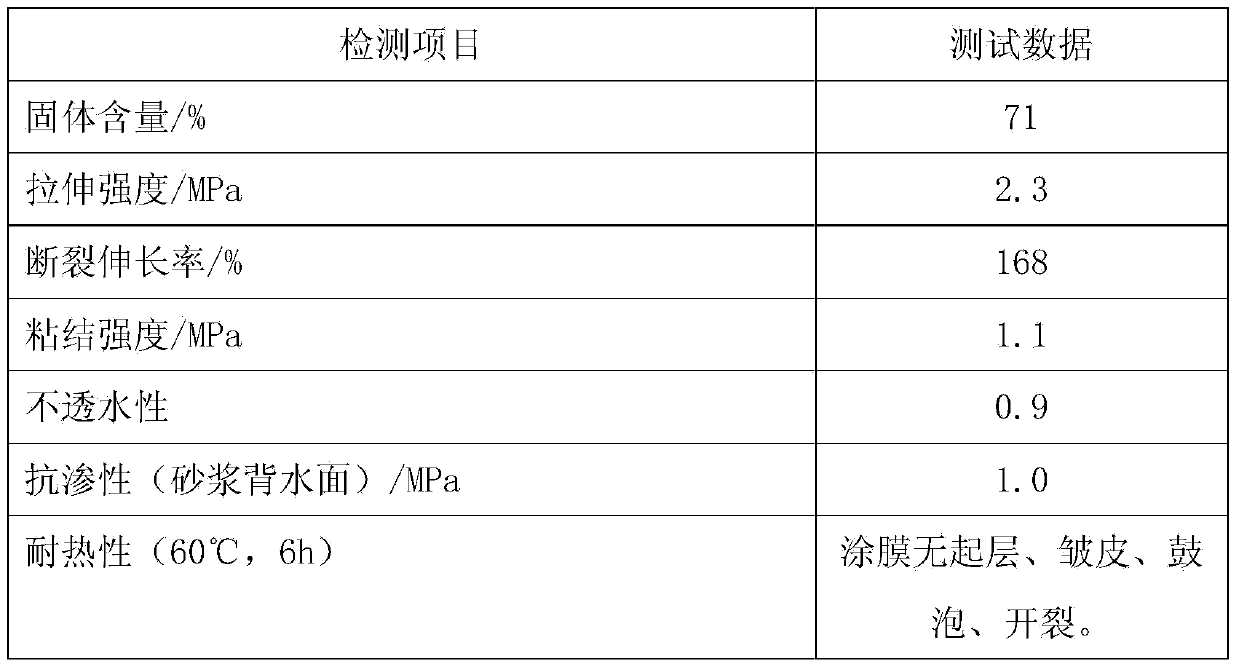

Examples

Embodiment Construction

[0033] A high-strength, high-strength, high-temperature-resistant, crack-resistant, and elastic waterproof coating is composed of a heat-resistant, crack-resistant, elastic film-forming liquid material and a cement mixing powder, and the mass ratio of the heat-resistant, cracking-resistant, elastic film-forming liquid material to the cement mixing powder is 3: 2. The specific preparation method is:

[0034] The first step prepares film-forming liquid material, comprises the following steps:

[0035] (1) Weigh the raw materials of the following components by weight (kg):

[0036] Pure acrylic elastic emulsion resin 92, fluorocarbon surfactant 4, silicone modified epoxy resin 3, alcohol ester twelve 3, defoamer 1.0, preservative 0.4, camphor essential oil 0.2;

[0037] (2) Put the pure acrylic elastic emulsion resin into the reaction kettle according to the metering ratio, and start stirring at the same time, every 15-20 minutes, add fluorocarbon surfactant, silicone modified e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com