A waterless cotton fabric dyeing process and a waterless dyeing device

A technology for fabric dyeing and cotton fabrics, applied in the direction of dyeing, plant fibers, textiles and paper making, etc., can solve the problems of low utilization rate of dyes and solvents, increase the amount of organic solvents, large sewage discharge, etc., and achieve dye adsorption. Good effect, good washing fastness and rubbing fastness, high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of water-free cotton fabric dyeing process, and it comprises the following steps:

[0032] a. Soak the cotton fabric in a 93°C mass concentration of 10% NaOH aqueous solution;

[0033] b. Use hot air at 57°C to dry the cotton fabric;

[0034] c. spraying volume concentration to described cotton fabric is the ethanol solution of the diacetyl of 18%;

[0035] d. Atomize the dyeing agent and spray it on the cotton fabric;

[0036] e. The cotton fabric is left to stand for 3 hours in an environment with a relative air humidity of 60%;

[0037] f. Ventilate and dry the cotton fabric at a temperature of 43°C;

[0038] The dyeing agent includes dichloro-s-triazine-based X-type decamethylcyclopentasiloxane suspension system with a mass concentration of 10%-70%.

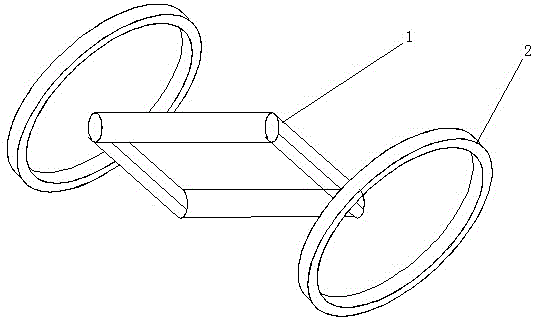

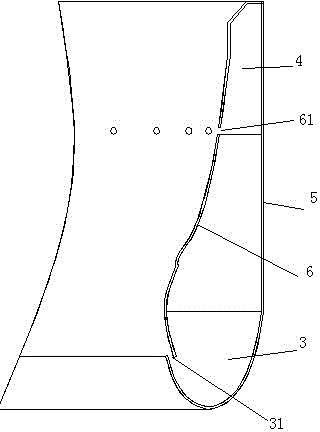

[0039] Said atomizing and spraying the dyeing agent onto the cotton fabric refers to spraying the atomized dyeing agent onto the cotton fabric from opposite ends of the cotton...

Embodiment 2

[0046] A kind of waterless cotton fabric dyeing process, it comprises the following steps:

[0047] a. Soak the cotton fabric in a 1% NaOH aqueous solution at 95°C;

[0048] b. Use hot air at 70°C to dry the cotton fabric;

[0049] c. spraying a volume concentration of 10% diacetyl ethanol solution to the cotton fabric;

[0050] d. Atomize the dyeing agent and spray it on the cotton fabric;

[0051] e. Put the cotton fabric in an environment where the relative air humidity is above 50% for 3 hours;

[0052] f. Ventilate and dry the cotton fabric at a temperature of 50°C;

[0053] The dyeing agent includes decamethylcyclopentasiloxane suspension system with a mass concentration of 10% mixed with dichloro-s-triazine-based type X and monochloro-s-triazine-based type K.

[0054] Said atomizing and spraying the dyeing agent onto the cotton fabric refers to spraying the atomized dyeing agent onto the cotton fabric from opposite ends of the cotton fabric after atomizing the dyein...

Embodiment 3

[0061] The present embodiment provides a kind of water-free cotton fabric dyeing process, and it comprises the following steps:

[0062] a. Soak the cotton fabric in an aqueous NaOH solution with a mass concentration of 15% at 90°C;

[0063] b. Use hot air at 40°C to dry the cotton fabric;

[0064] c. spraying a volume concentration of 20% diacetyl ethanol solution to the cotton fabric;

[0065] d. Atomize the dyeing agent and spray it on the cotton fabric;

[0066] e. The cotton fabric is left to stand for 3 hours in an environment with a relative air humidity of 80%;

[0067] f. Ventilate and dry the cotton fabric at a temperature of 30°C;

[0068] The dyeing agent comprises a decamethylcyclopentasiloxane suspension system with a mass concentration of 10%-70% mixed with monochloro-s-triazine-based K-type and vinylsulfone-based KN-type.

[0069] Said atomizing and spraying the dyeing agent onto the cotton fabric refers to spraying the atomized dyeing agent onto the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com