Micro mechanical sensor with two layers of base plates

A technology of micromechanical sensors and substrates, which is applied in the direction of instruments, piezoelectric effect/electrostrictive or magnetostrictive motors, optical waveguide coupling, etc. Measure the impact and other issues to achieve the effect of easy control of process quality, low cost and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

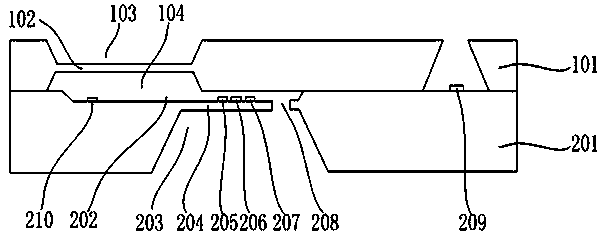

[0019] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0020] Such as figure 1 The shown micromechanical sensor with a two-layer substrate includes: a first substrate made of a single crystal silicon wafer

[0021] Board 101, second substrate 201, the second substrate 201 is the base of the micromechanical sensor with two-layer substrate, the first substrate 101 is placed on the second substrate 201 and connected with the second substrate 201, wherein,

[0022] The first substrate 101 is processed by the MEMS process to obtain a first cavity 103 with an upward opening and a second cavity 104 with a downward opening. The part of the first substrate between the first cavity 103 and the second cavity 104 constitutes the first film. sheet 102,

[0023] The second substrate 201 is processed by a MEMS process to obtain a third cavity 202 with an upward opening and a fourth cavity 203 with a downward opening. The part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com