Preparation method of annular-structure thermo-electric device

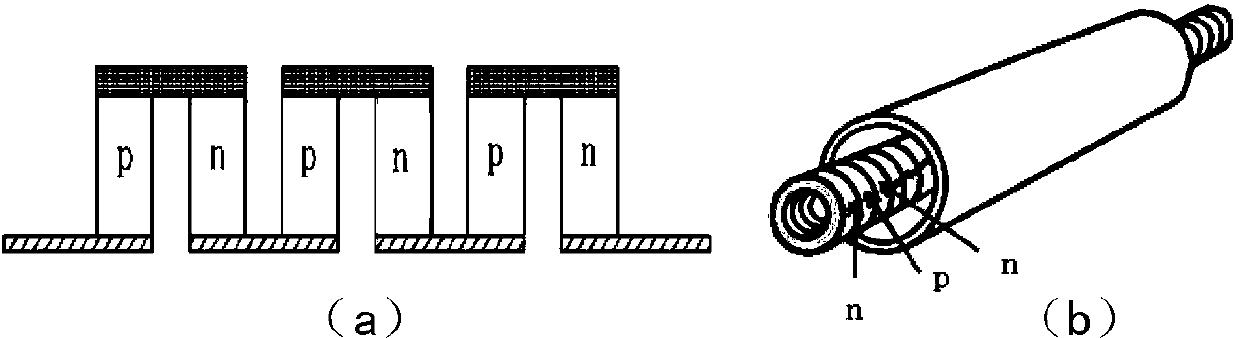

A thermoelectric device and ring-shaped technology, which is applied in the field of preparation of ring-shaped thermoelectric devices, can solve the problems of no relevant reports, few researches on thermoelectric devices, complicated preparation process, etc., and achieve the goal of preventing heat loss, ensuring mechanical strength and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

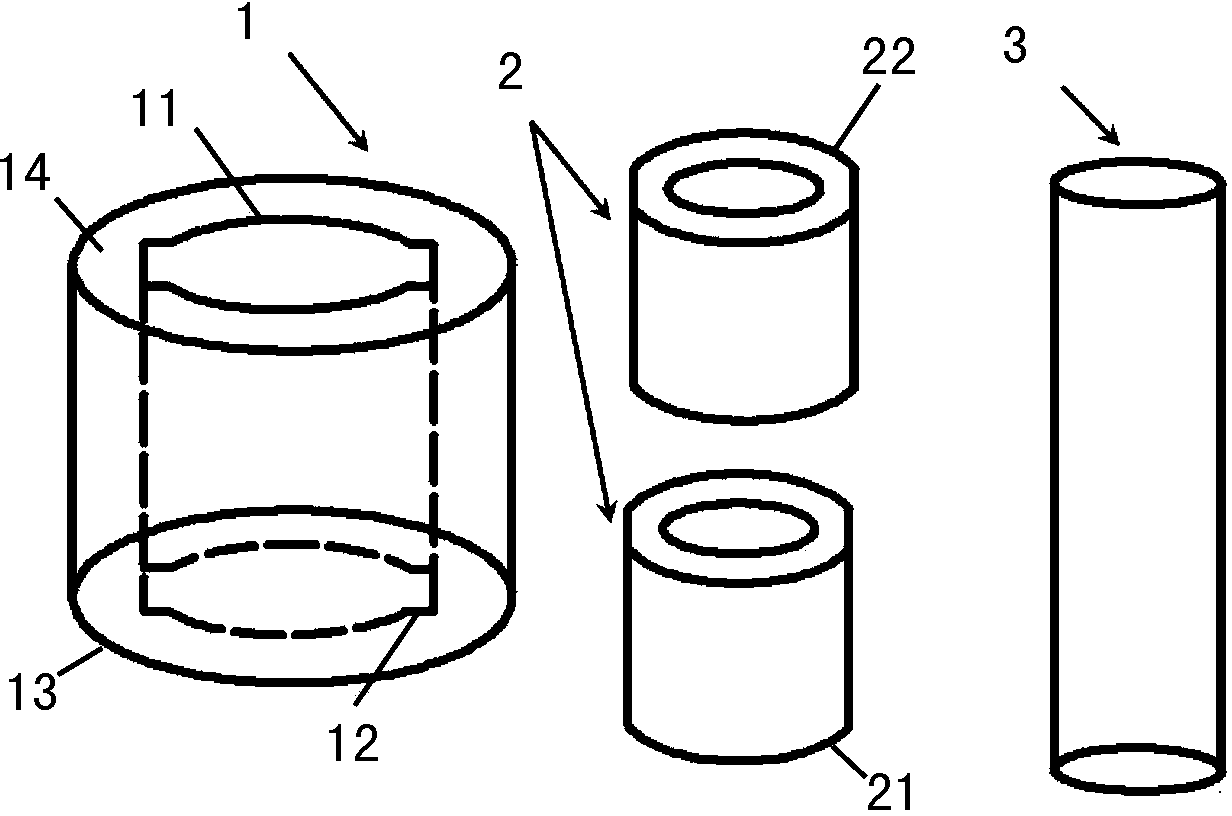

[0042] see Figure 2 to Figure 6 The embodiment, the preparation method of the ring-shaped thermoelectric device of the present invention includes: placing the first metal connection layer 4 on the groove 12 arranged longitudinally on the inner wall 11 of the hollow mould; inserting the central rod 3 into the mould. ; The first thermoelectric material 5, the isolation layer material 6 and the second thermoelectric material 7 are sequentially laid in the annular hollow part between the center rod 3 and the shell 1 of the mold; the mold is sintered; the center rod is removed after the sintering is completed 3 and remove the isolation layer material 6 between the first thermoelectric material 5 and the second thermoelectric material 7 to obtain an annular thermoelectric single couple 9; and the inner walls 90 of multiple annular thermoelectric single couples 9 are connected by a second metal connection layer 8 To obtain a ring-shaped thermoelectric device.

[0043] According to ...

Embodiment 1

[0067] First choose the general formula Mo x Cu 1-x The molybdenum-copper alloy material is used as the first metal connection layer 4, wherein x (weight%) is 20≤ x ≤80. Preferably, in this embodiment, the Mo formed by cold rolling is selected. 40 Cu 60 The alloy sheet is used as the first metal connection layer 4, and its thickness may be 0.5 mm.

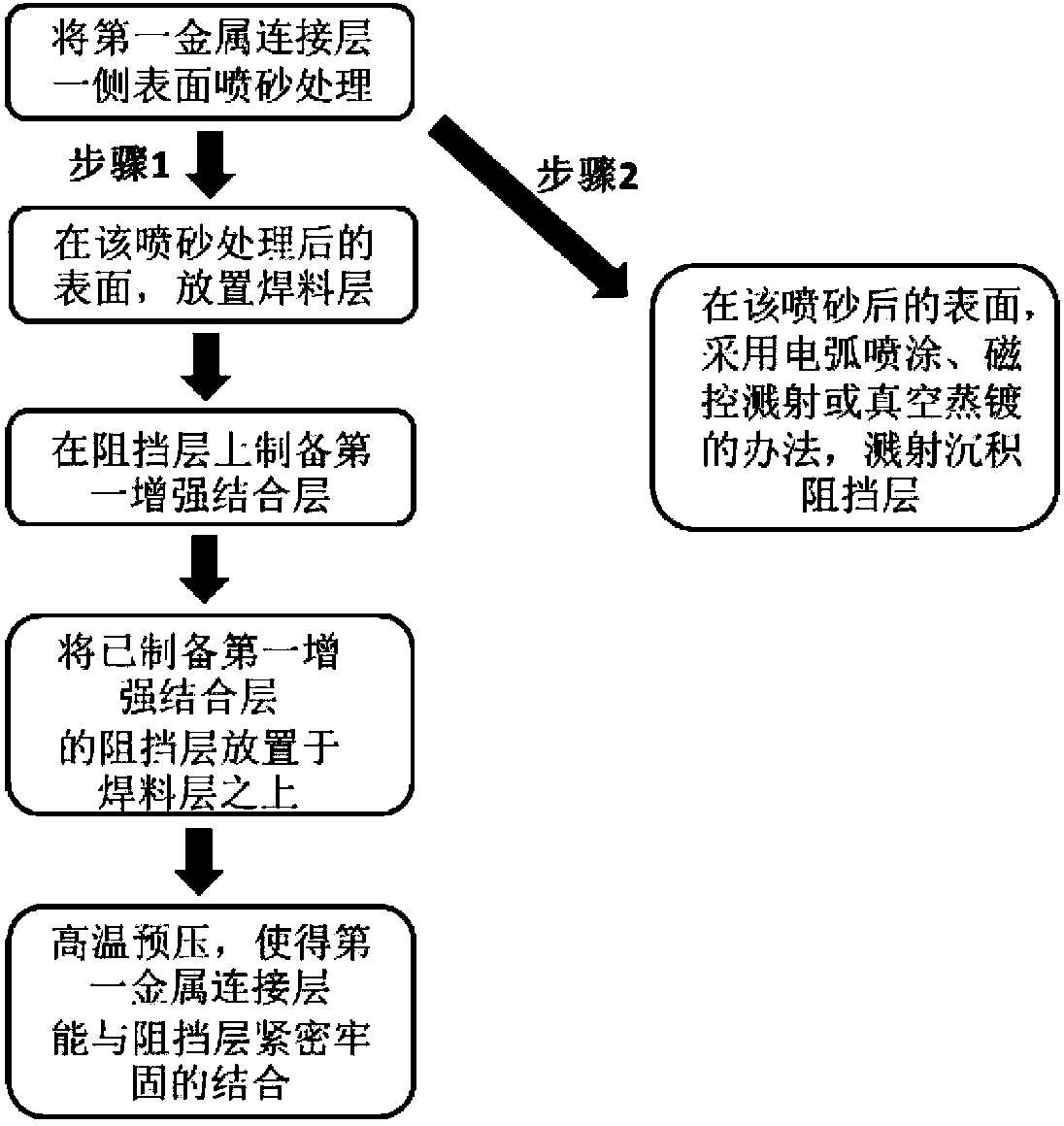

[0068] The first metal connection layer 4 is pretreated. Sand blasting can be performed on one side of the first metal connection layer 4 to remove oxides on the surface and make the surface rough to enhance the bonding force between it and the barrier layer. In the blasting treatment, the blasting pressure can be 0.1-0.5 MPa, the blasting time can be 30 seconds-3 minutes, and high-purity corundum can be used for the blasting treatment, for example.

[0069] After the sandblasting treatment is completed, the first metal connection layer 4 may be ultrasonically cleaned to remove surface impurities. The solvent used for the u...

Embodiment 2

[0079] Compared with Example 1, the main difference of Example 2 is the preparation process of the first metal connection layer 4, the first enhanced bonding layer, and the barrier layer (such as image 3 shown). Therefore, descriptions of those steps that are the same as in Embodiment 1 are omitted in the following description.

[0080] Present embodiment 2 is still the same as in embodiment 1, selects the Mo of cold-rolled forming for use 40 Cu 60 The alloy sheet is used as the first metal connection layer 4, and its thickness may be 0.3 mm.

[0081] On top of this first metal connection layer 4 a solder layer is placed. The solder layer can be selected from Ag-Cu alloy solder pads. Preferably, the content of Cu can be 50%, the rest is Ag and a small amount of unavoidable impurity elements Bi or Zn; the thickness of the Ag-Cu alloy solder sheet used can be 0.1mm.

[0082] On the upper surface of this solder layer, a barrier layer to which a first bond-enhancing layer ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com