Polymer micro-fluidic chip and preparation method thereof

A microfluidic chip and polymer technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., to achieve the effect of promoting practicality and industrialization, good cross-section consistency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A polymer microfluidic chip is composed of a substrate, a cover sheet, a sample pool, a buffer solution pool, and a waste liquid pool. The substrate is provided with a rice-shaped micro channel, and the ends of the micro channel are provided with grooves. A hollow micro-extrusion tube with a rectangular cross-section is arranged in the micro-extrusion tube. The micro-extrusion tube is just completely contained in the groove of the substrate and has the same length. The inner diameter of the micro-extrusion tube is equal to the cross-sectional diameter of the micro channel.

Embodiment 2

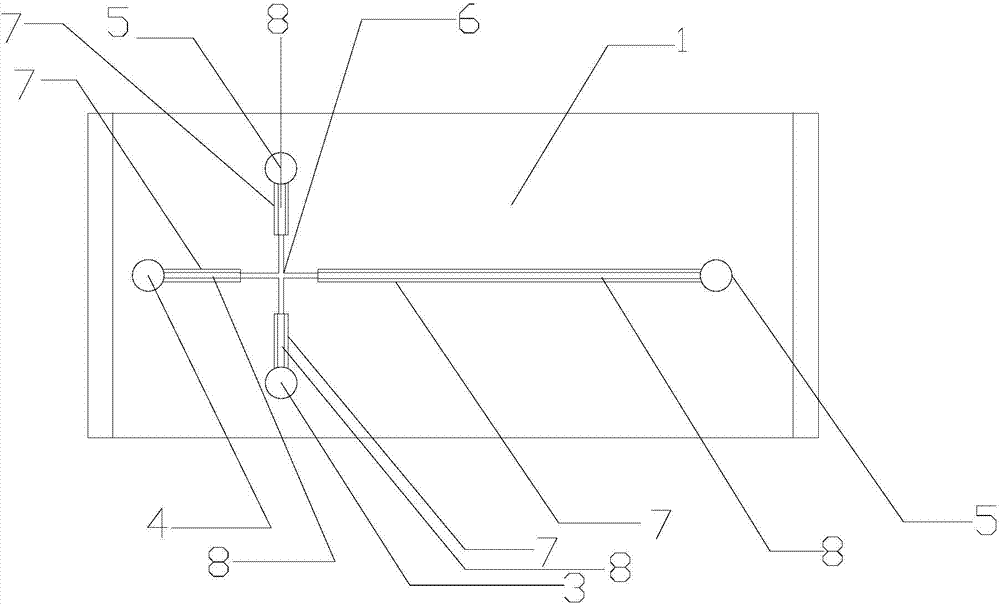

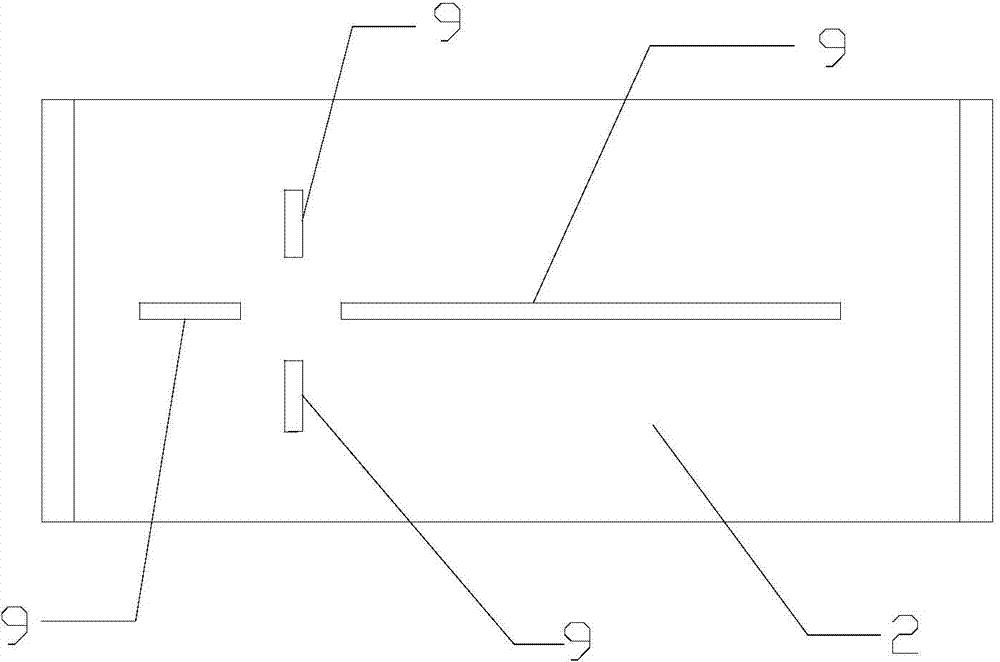

[0037] Such as Figure 1-2 The polymer microfluidic chip shown is composed of a substrate 1, a cover sheet 2, a sample cell 3, a buffer reservoir 4, and a waste liquid reservoir 5. The substrate 1 is provided with a cross-shaped micro channel 6, The cross-section of the micro-channel is rectangular, the size of the rectangular cross-section of the micro-channel is 120μm*120μm, the ends of the micro-channel 6 are provided with grooves 7, and the corresponding positions on the cover sheet 2 are also provided with grooves 9 matching the grooves 7. The cross section of the groove 7 of the film and the groove 9 of the cover film are both semicircular, and the radius is 0.5±0.005mm. A hollow section is provided between the groove 7 of the base film and the groove 9 of the cover film, which is circular. The micro-extrusion tube 8 has an outer diameter of 1.0±0.005 mm and an inner diameter of 100 μm, and the length of the micro-extrusion tube is equal to the length of the corresponding...

Embodiment 3

[0039] A polymer microfluidic chip composed of a substrate, two cover sheets, a sample pool, a buffer solution pool, and a waste liquid pool. The two sides of the substrate are respectively provided with micro channels, and one side is a cross-shaped micro channel , One side is a rice-shaped micro channel, the cross section of all the micro channels is rectangular, the ends of the micro channels are provided with grooves, and the corresponding positions on the two cover sheets are also provided with the grooves on the corresponding side of the substrate. Matching grooves, the cross-sections of the grooves are all semicircular, and a hollow micro-extrusion tube with a circular cross-section is arranged between the groove on the substrate and the groove on the corresponding cover sheet. The lengths of the grooves of the outlet pipe are equal, and the cover sheets are respectively arranged on both sides of the base sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com