Reinforced environment-friendly carbon electrode and preparation method thereof

A carbon electrode, an environmentally friendly technology, applied in the field of carbon electrodes, can solve the problems of insufficient utilization of waste carbon fibers, pollute the environment, pollute the atmosphere, etc., achieve the effects of performance indicators and quality improvement, energy saving, and coal saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

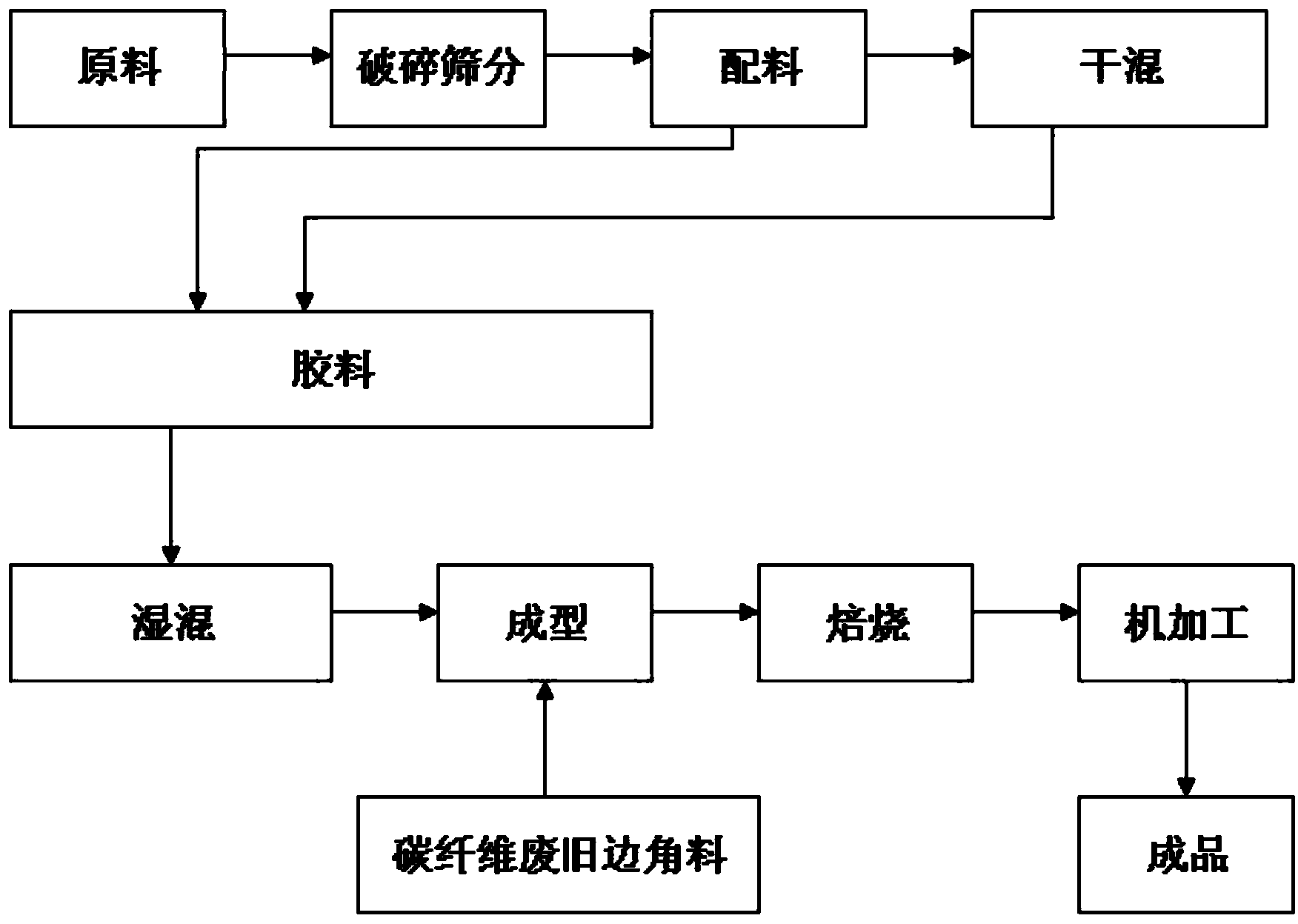

Method used

Image

Examples

preparation example Construction

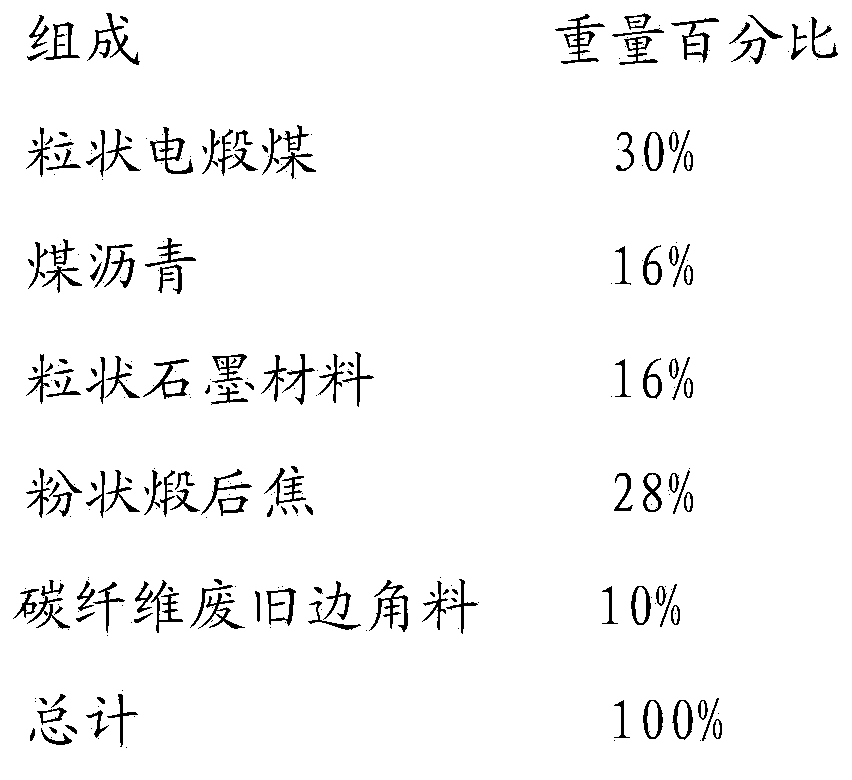

[0031] Enhanced preparation of environmentally friendly carbon electrodes

[0032] Feeding formula:

[0033]

[0034] Preparation Process:

[0035] (1) Preparation of raw electrode products: crush the electric calcined coal into particles with a particle size of 4mm to 16mm, crush the bulk graphite material, and sieve it into specified large, medium and small particles of different specifications, and enter the automatic batching system For batching, take the specified (recipe amount) dry material amount, convey it into the upper layer of the double-layer kneading pot by a screw, carry out heat treatment on the dry material, heat it to 150-185°C, and keep it for 20 minutes to obtain the dry material; The back coke is crushed into a powder with a particle size of 0.05mm to 0.075mm, put into the lower kneading pot together with coal tar pitch and mixed for 20 minutes, and the temperature is controlled at 140-160°C to obtain the rubber compound; the dry powder prepared in the...

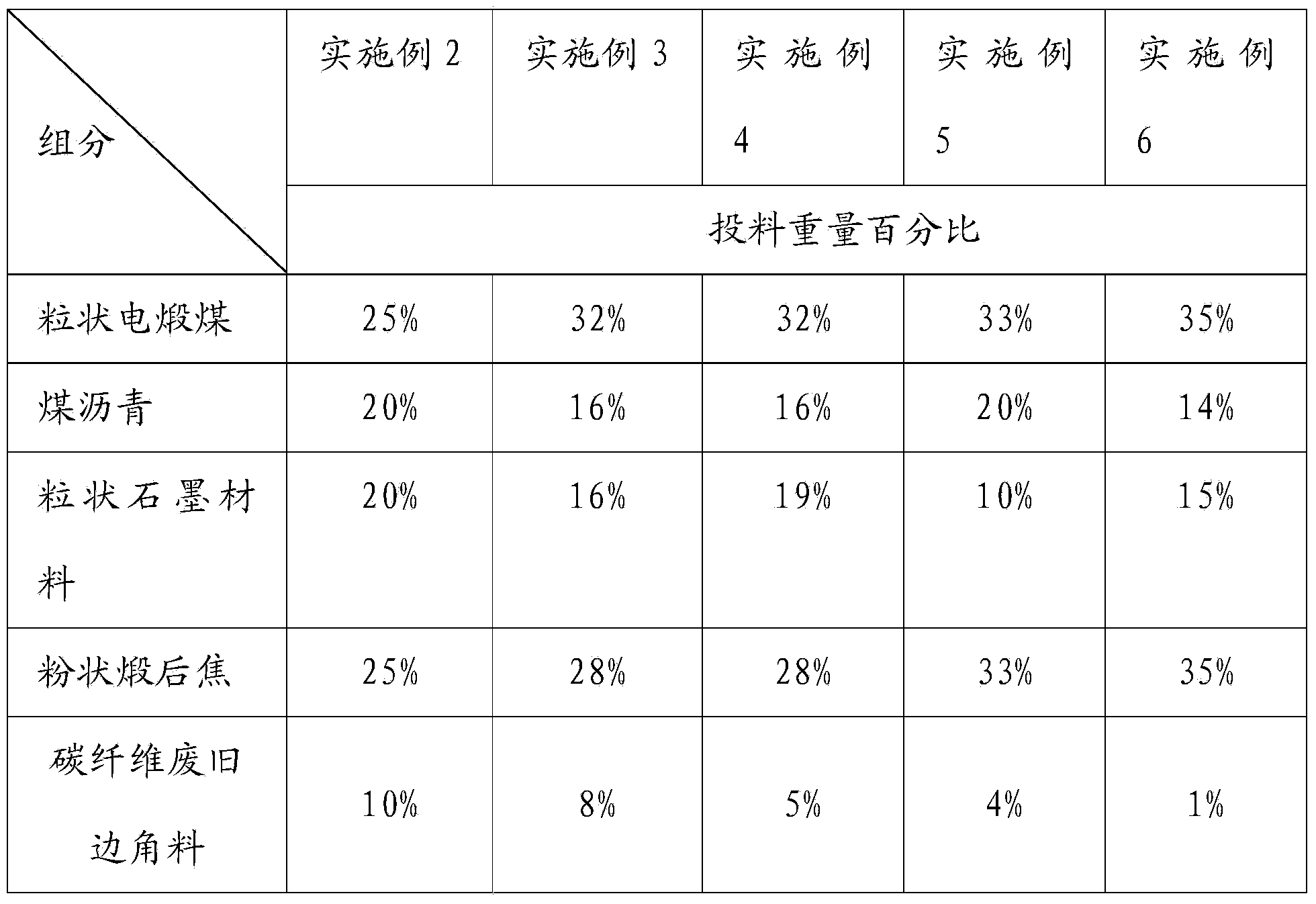

Embodiment 2~6

[0040] Enhanced environment-friendly carbon electrode, the formula is shown in Table 1.

[0041] Table 1 Embodiment 2~6 strengthens the formula of environment-friendly type carbon electrode

[0042]

[0043] Preparation Process:

[0044] (1) Preparation of raw electrode products: crush the electric calcined coal into particles with a particle size of 4mm to 16mm, crush the bulk graphite material, and sieve it into specified large, medium and small particles of different specifications, and enter the automatic batching system Carry out batching, weigh the amount of dry material specified (recipe amount), convey it into the upper layer of the double-layer kneading pot by a screw, carry out dry material heat treatment, heat to 150~185 ℃, keep 15-25 minutes (wherein, embodiment 2 -4 is 20 minutes, Example 5 is 15 minutes, and Example 6 is 25 minutes), to obtain a dry material; crush the calcined coke into a powder with a particle size of 0.05mm to 0.075mm, and put it into the ...

Embodiment 7

[0048] Embodiment 7 index test

[0049] The corresponding product quality indicators of the carbon electrodes of Examples 1-6 were tested according to the methods in relevant industry standards, and the results are shown in Table 2. Among them, the test method of resistivity refers to: GB / T24525-2009, the test method of tensile strength refers to: GB / T8721-2009, the test method of flexural strength refers to: GB / T3074.1-2008, the test of thermal expansion coefficient Method reference: GB / T3074.4-2003, volume density test method reference: GB / T24528-2009, ash content test method reference: GB / T1429-2009.

[0050] Table 2 Comparison of the indicators of the environment-friendly carbon electrodes in Examples 1 to 6 and the standard carbon electrodes

[0051]

[0052] The results in Table 2 show that the carbon electrode of the present invention (carbon electrode containing carbon fiber) is much better than the industry standard of ordinary carbon electrode (not containing car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com