Water treatment system and method for synchronously removing ammonia nitrogen and nitrate nitrogen in water by using water treatment system

A water treatment system and water removal technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low pollutant degradation rate, secondary pollution, etc., and the effect is obvious , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

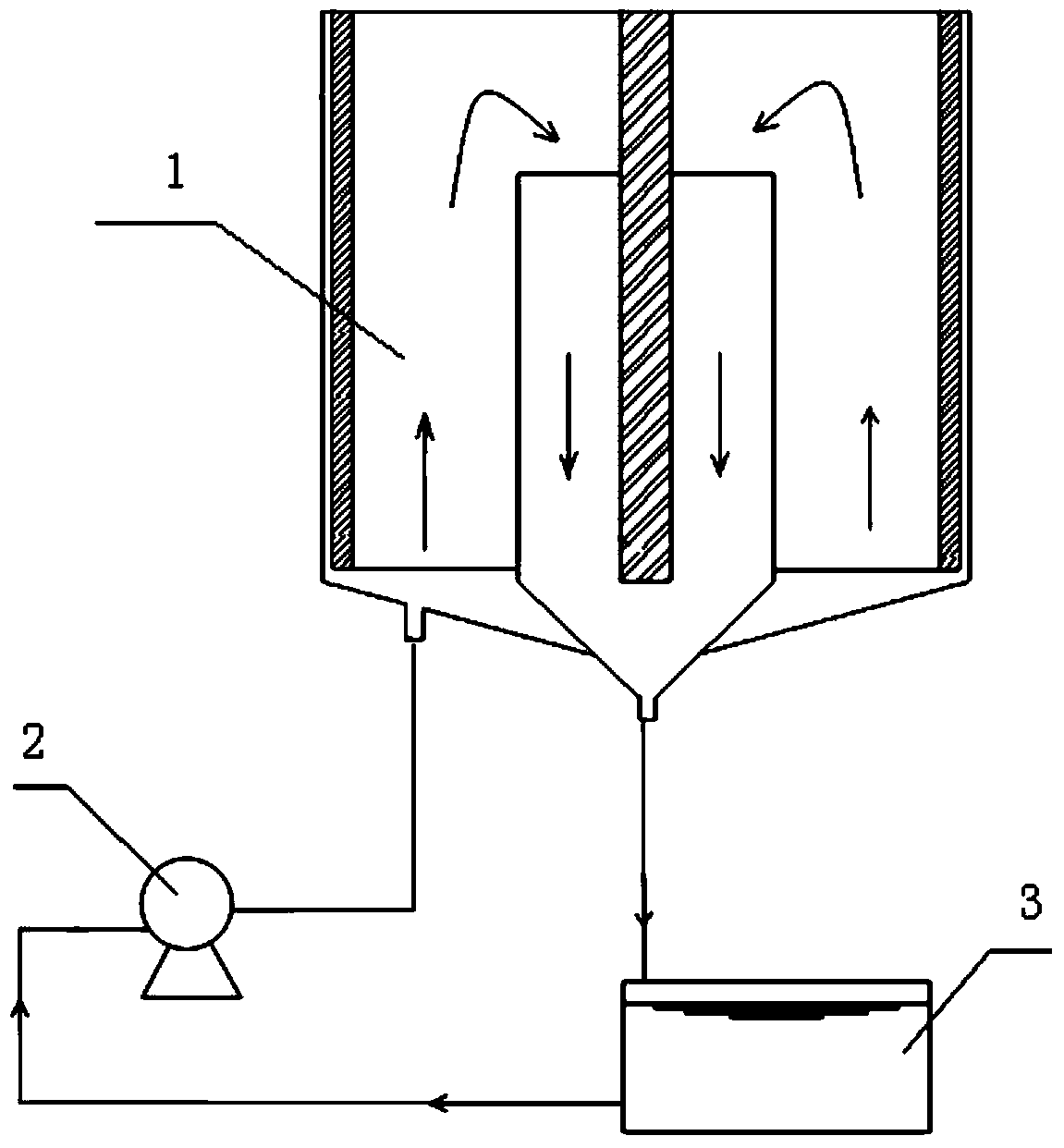

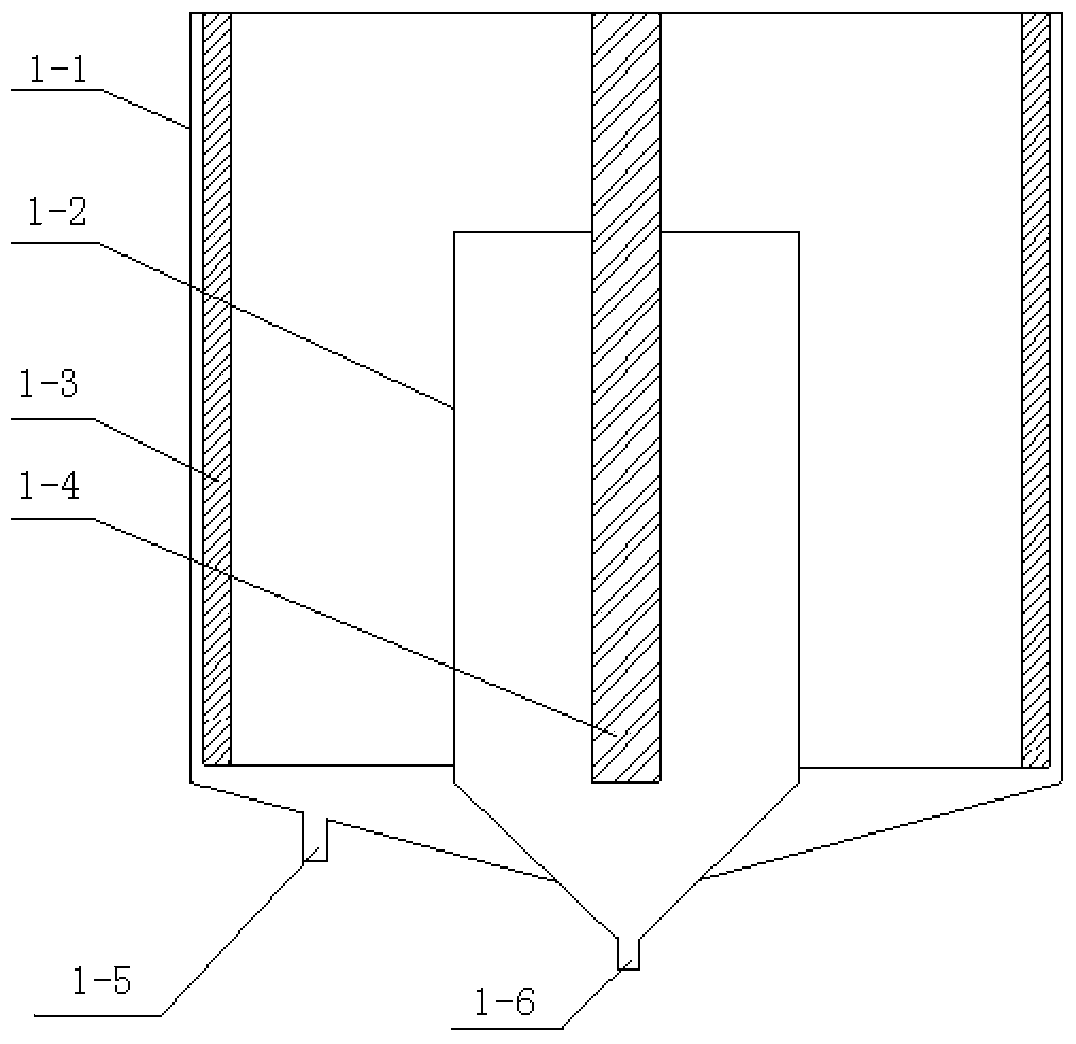

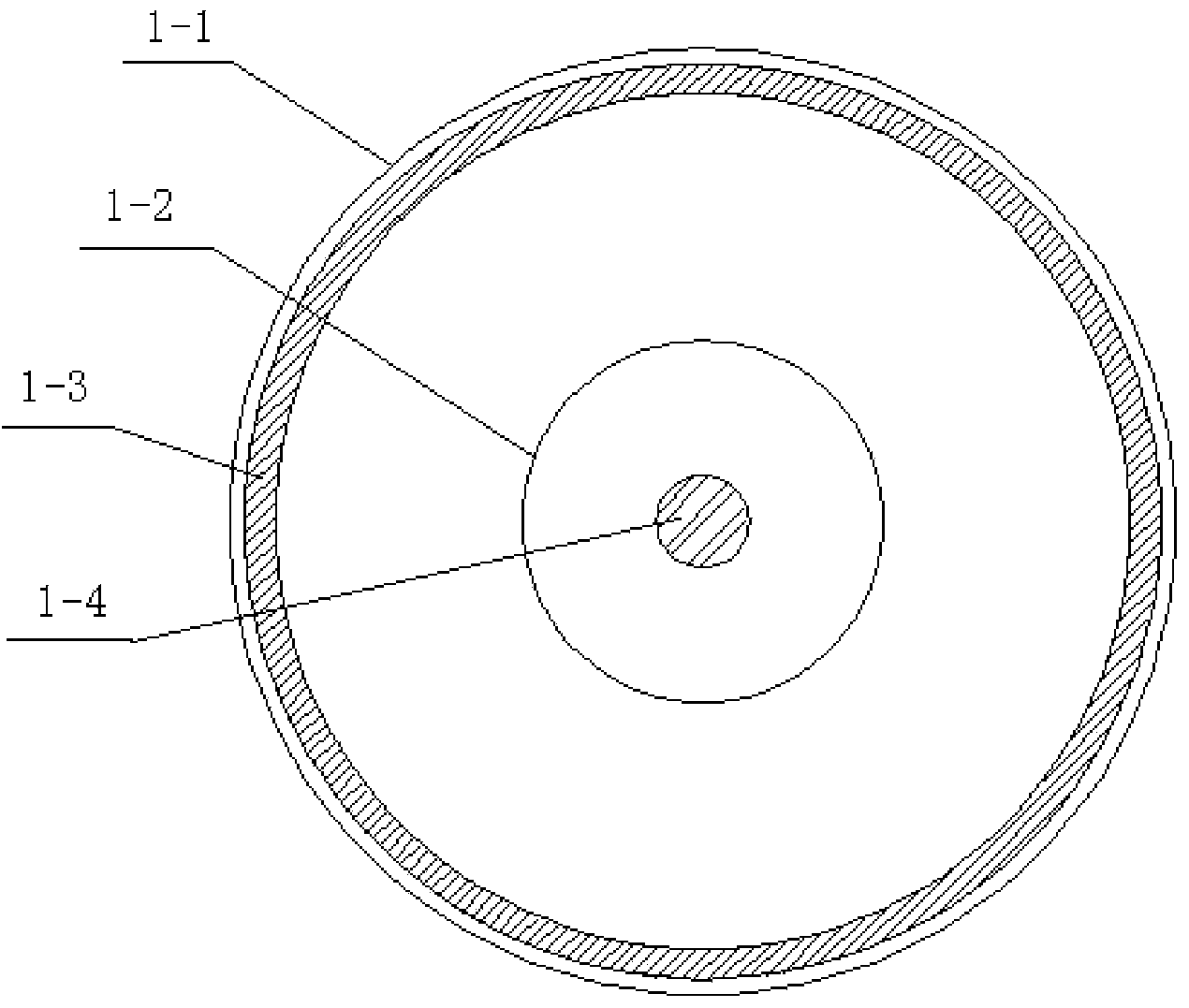

[0019] Embodiment 1: A water treatment system in this embodiment includes a cylindrical sleeve reactor 1, a peristaltic pump 2 and a water storage tank 3; wherein the cylindrical sleeve reactor 1 consists of an outer cylinder 1-1, a water-proof inner cylinder 1-2. Composed of cylindrical stainless steel cathode 1-3 and rod-type DSA anode 1-4; the water-proof inner cylinder 1-2 is set in the outer cylinder 1-1, and the rod-type DSA anode 1-4 is located in the water-proof inner cylinder 1-4 In 2, the inside of the water-proof inner cylinder 1-2 is the anode area, and the cylindrical stainless steel cathode 1-3 is arranged between the outer cylinder 1-1 and the water-proof inner cylinder 1-3, and the outer cylinder 1-1 and the water-proof inner cylinder The area between 1-2 is the cathode area, and the water inlet 1-5 is set at the bottom of the cathode area, and the water outlet 1-6 is set at the bottom of the anode area; The water inlets 1-5 are connected, and the water outlets...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the height of the water-separating inner cylinder 1-2 is 1 / 2 to 2 / 3 of that of the rod-type DSA anode 4; the others are the same as Embodiment 1.

[0029] This embodiment can ensure that the sewage maintains a good push-flow state in the reactor, and the separator can also ensure the continuity of the water flow while separating the cathode and the anode.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the volume ratio of the cathode region to the anode region is (1.4-2.5): 1; other aspects are the same as Embodiment 1 or Embodiment 2.

[0031] The design of this embodiment can ensure the complete reduction of nitrate nitrogen in the cathode region under the premise that the cathode and anode provide the same amount of electrons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com