Purification oxygen flotation aeration device

An aeration device and oxygen technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of difficult maintenance and replacement, low power efficiency, uneven air distribution, etc., and achieve smooth flow of rich oxygen High transfer rate, improved dissolved oxygen capacity, and improved efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

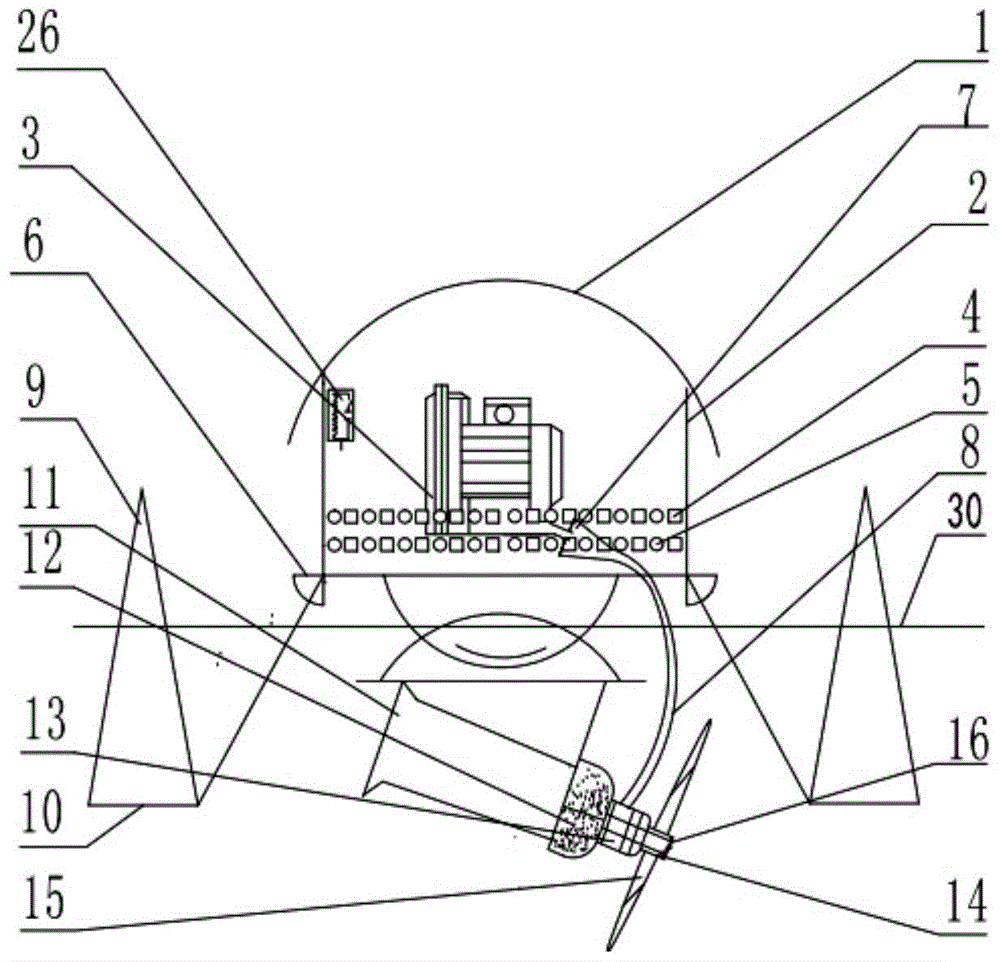

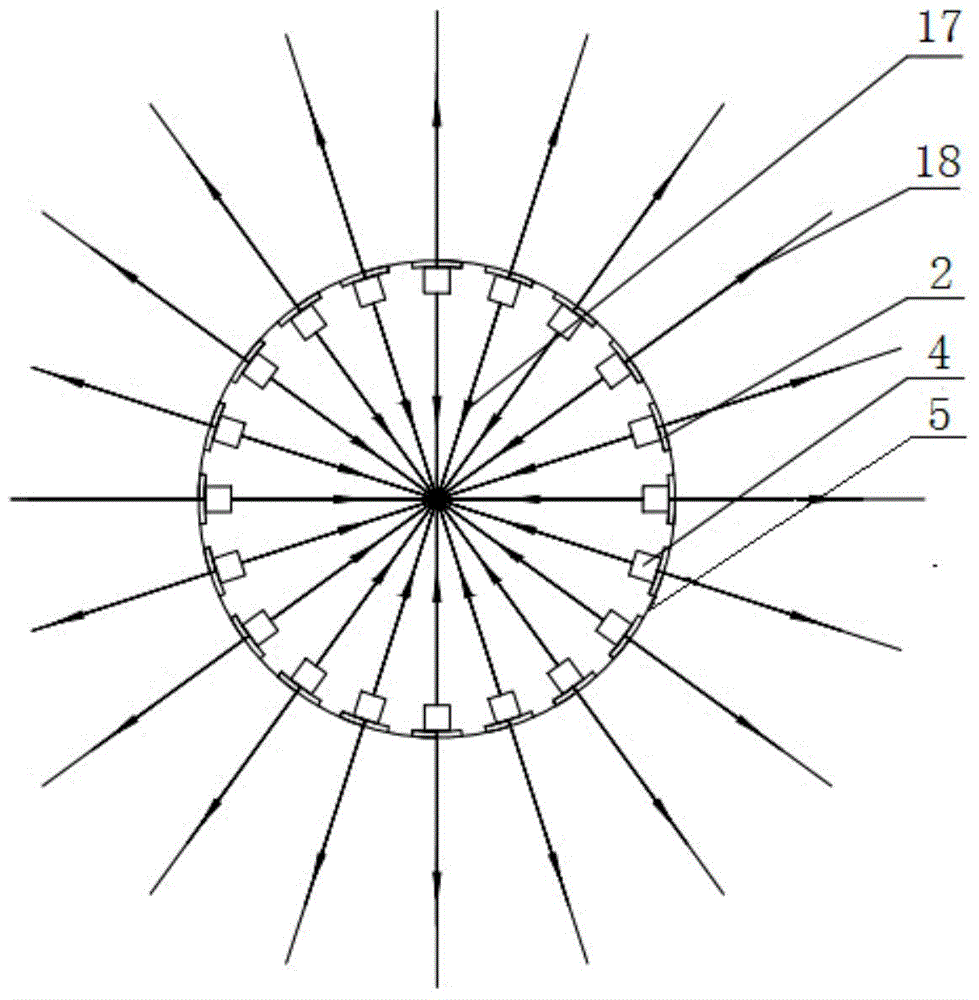

[0035] Refer to on the basis of embodiment 1 figure 2 . 2 is a vertical cylinder; 4 is a polyoxygen rare earth permanent magnet; 5 is an air inlet; these polyoxygen rare earth permanent magnets 4 are circularly arranged to form a synthetic magnetic force field in the direction of the magnetic force line, pointing to the axis of the vertical cylinder to the axis When the heart is focused, the magnetic force lines of the other magnetic pole radiate outward, forming a space with high gradient and strong magnetic field. The oxygen (paramagnetic substance) passing through the periphery of the air inlet hole 5 is sucked in; and the nitrogen (diamagnetic substance) is excluded (at least not attracted). Here it is the efficient oxygen gathering device of the present invention.

Embodiment 3

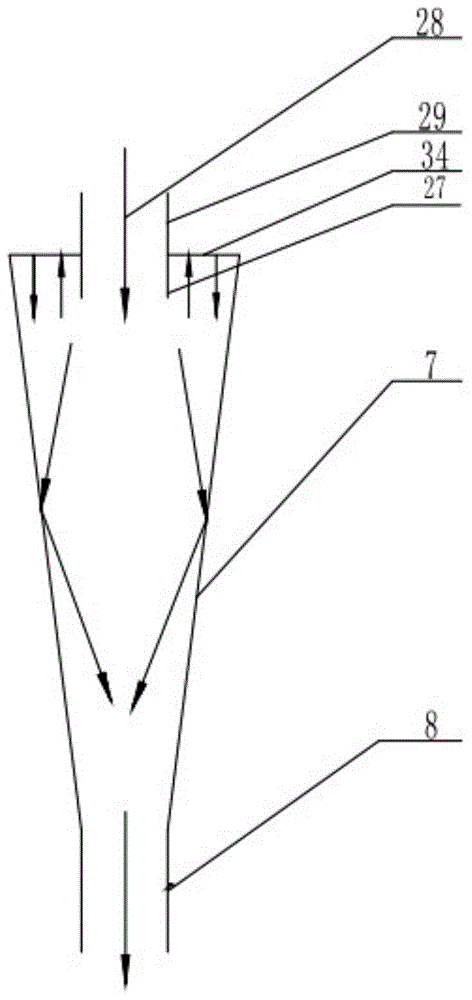

[0037] On the basis of embodiment 1, with reference to image 3 , this is the vortex-free storage air supply bin 7, which is conical, and the high-end high-pressure fan outlet pipe 29 extends from the plane of the bottom of the cone into the vortex-free storage air supply bin 7, and the intake extension pipe 27 is the high-end high-pressure fan outlet. Pipe 29 stretches into the part in the air supply chamber 7 without vortex storage; 8 is a non-resistance air guide pipe; 28 is the direction in which oxygen-enriched high-pressure air enters the airflow in 7 miles of air supply chamber without vortex storage; Most of them flow into the non-resistance air duct 8 very smoothly, so there is almost no eddy current loss.

Embodiment 4

[0039] On the basis of embodiment 1, with reference to Figure 4 , the shaft coupling 25 in the sealed chamber 12 of the built-in nanometer graphite powder connects the submersible motor output shaft 21 with the ultrashort hollow shaft 14. Ultra-short hollow shaft 14 passes bearing 24, air supply chamber 13 and stretches in the water again. When the shaft coupling 25 rotated at a high speed, it could lift up the surrounding air to form a high-speed rotating wind, and simultaneously blow up the nano-graphite powder 23 in the sealed chamber 12. Coupling 25, bearing 24 etc. carry out heat dissipation and can also supplement lubricating quality for coupling 25 and bearing 24 properly at the same time, exempt from the trouble of often adding lubricating grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com