Preparation method of heat-dissipating acrylic adhesive tape

An acrylate, heat-dissipating technology, used in adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of high heat dissipation requirements of electronic components, less effective heat dissipation than imagined, and reduced size. Achieve the effect of facilitating heat dispersion and transmission, avoiding heat concentration, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: a preparation method of heat-dissipating acrylic adhesive tape, comprising a PET film with a thickness of 0.004 mm to 0.025 mm, an aluminum foil layer is coated on the upper surface of the PET film, and a heat-conducting adhesive layer is coated on the lower surface of the PET film. The paper is pasted on the other surface of the thermally conductive adhesive layer, and the thermally conductive adhesive layer is obtained by the following process:

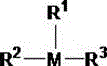

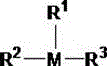

[0027] In the first step, uniformly mix 0.1-0.2 parts of cross-linking agent with 70-150 parts of toluene, 50-150 parts of ethyl acetate and 50-70 parts of methyl ethyl ketone to obtain a dilution. The cross-linking agent is selected from the following general formula ( )compound of,

[0028]

[0029] ( );

[0030] In the formula, R 1 , R 2 , R 3 Each independently represents the residue after removing one hydrogen atom from the carbon chain of a ketone with 3 to 8 carbon atoms, and M represents Fe or Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com