Production line and preparation method of sludge and straw mixed fuel

A technology of mixing fuel and production line, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of low diffusion contact between sludge and hot air, low production efficiency, low evaporation efficiency, etc., to achieve good sludge drying effect, The effect of improving quality and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

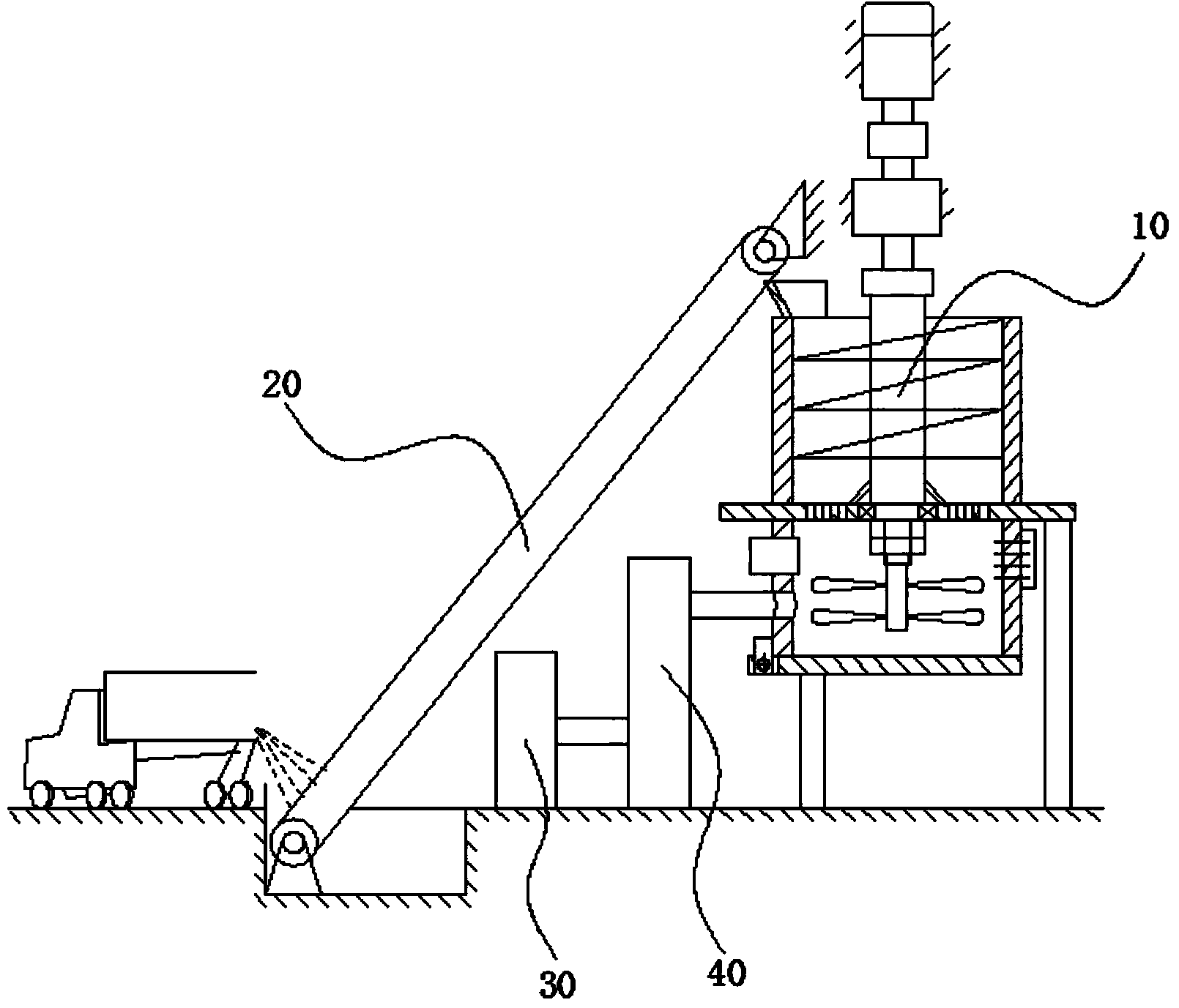

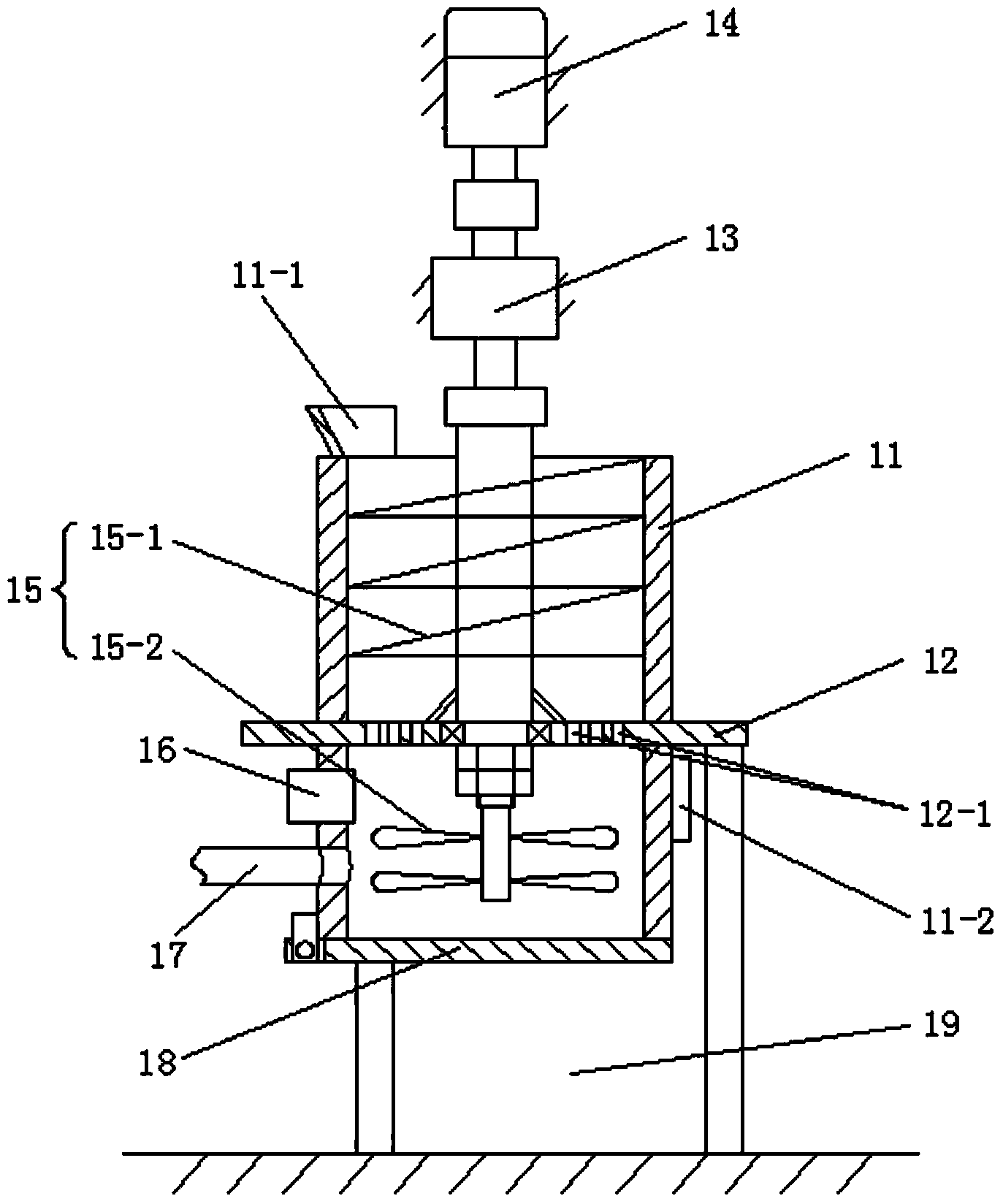

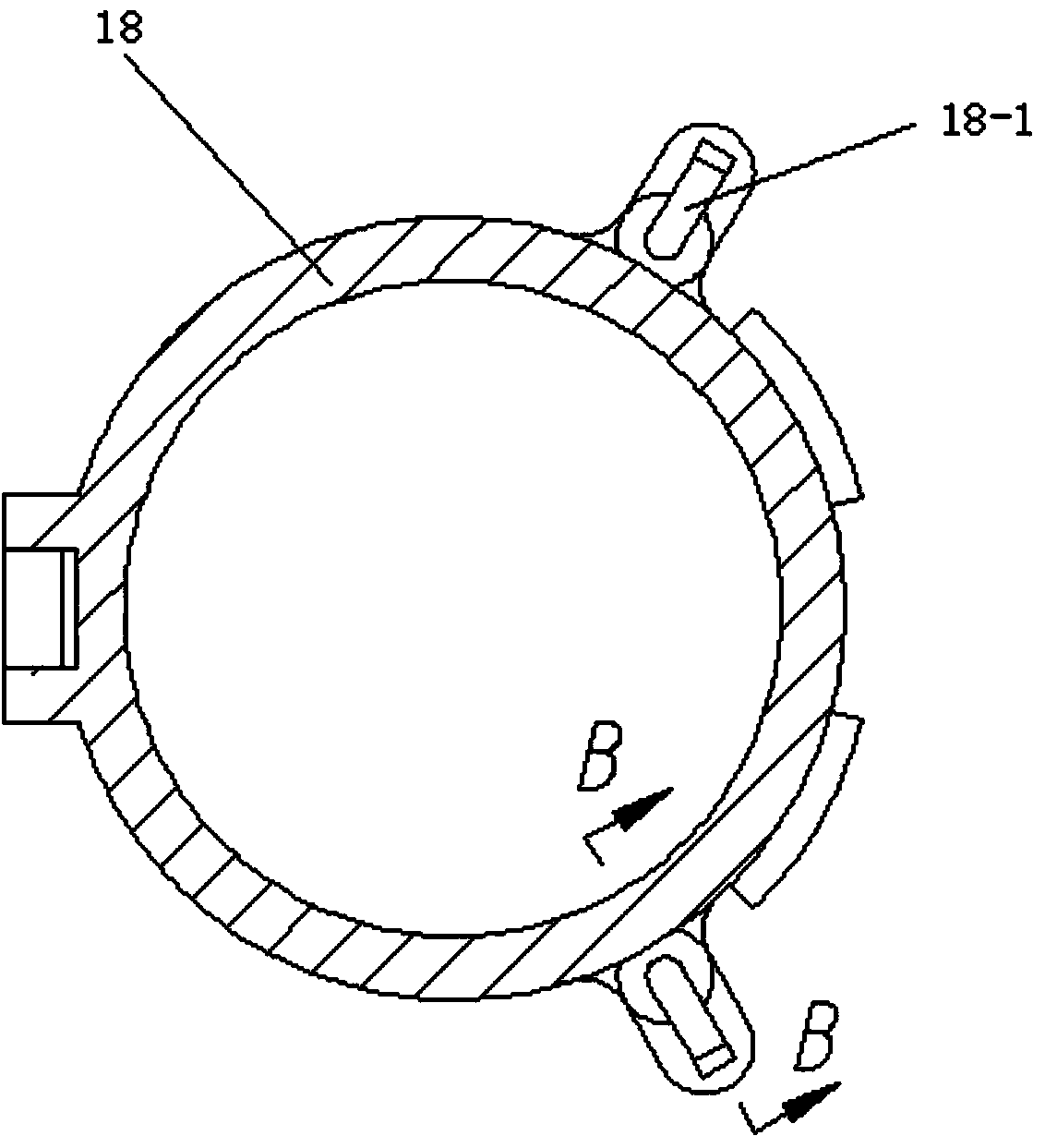

[0026] See Figure 1 to Figure 4 , the present invention includes a sludge belt conveyor 20, a straw pulverizer 30, a straw pneumatic conveyor 40, and a sludge and straw granulation and drying integrated machine 10; the sludge and straw granulation and drying integrated machine includes a sleeve 11, a granulation device 12, reduction box 13, motor 14, screw rod shafting 15, bearing, microwave generator 16; the upper end of the sleeve 11 is provided with a mud bucket 11-1 communicated with the sleeve 11, a motor 14 and a reduction box 13 ; The screw shaft system 15 is installed in the entire sleeve 11, and the upper end of the screw shaft system 15 is connected with the motor 14 through a coupling and a reduction box 13; the granulator 12 separates the sleeve 11 into feeding area and drying area; the screw shaft system 15 passes through the granulator 12, and a bearing is provided between the granulator 12; the part of the screw shaft system 15 located in the feeding area is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com