SCR (Selective Catalytic Reduction) denitration catalyst robot equipment and automatic deviation rectifying method

A denitration catalyst and robot technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of high cutting position requirements, secondary damage to products, affecting product quality, etc., to improve production efficiency and automation level. , high degree of automation, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

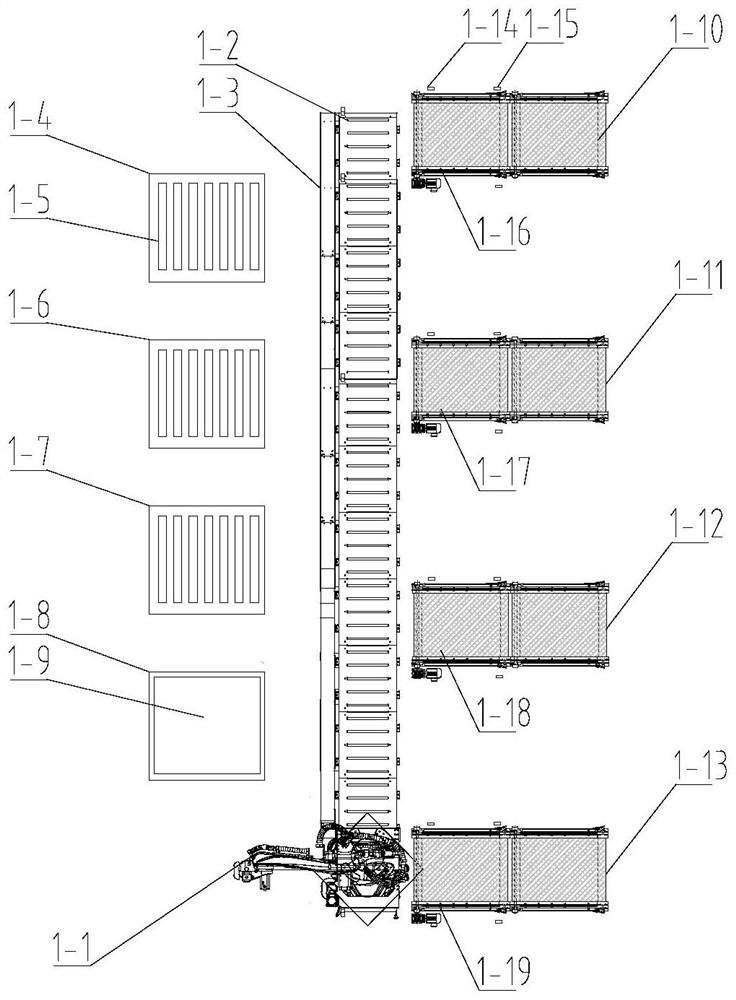

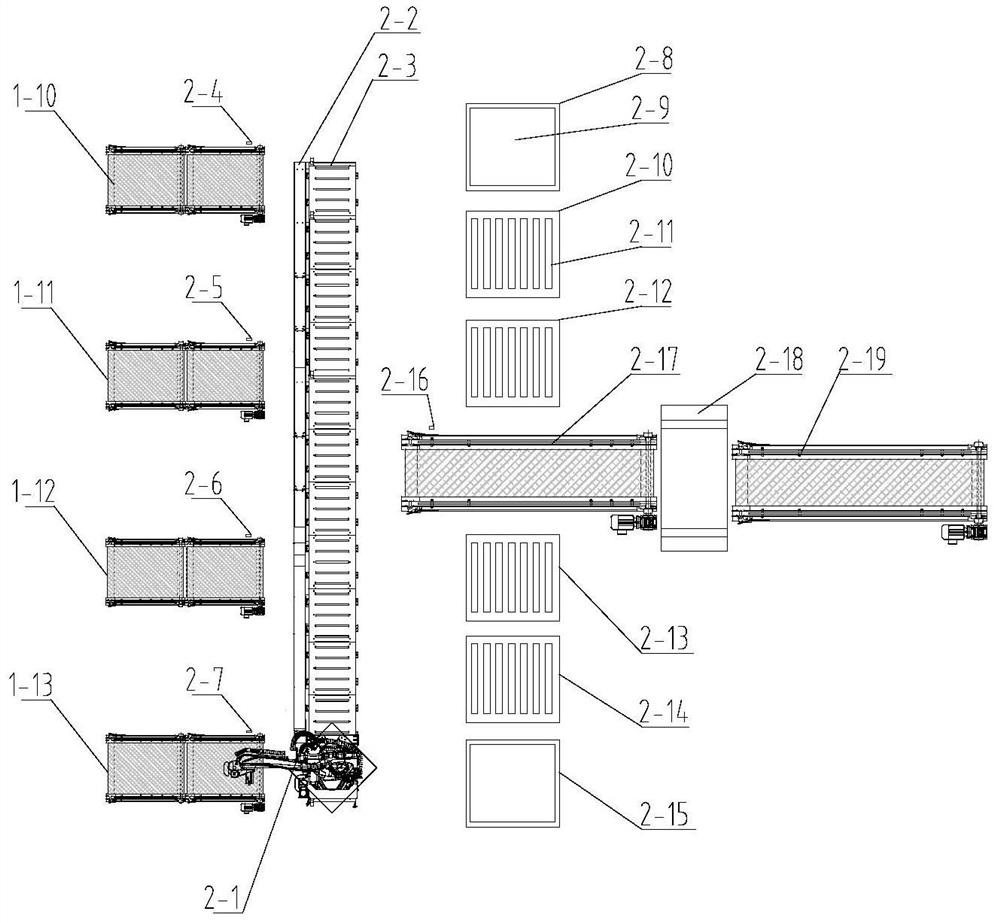

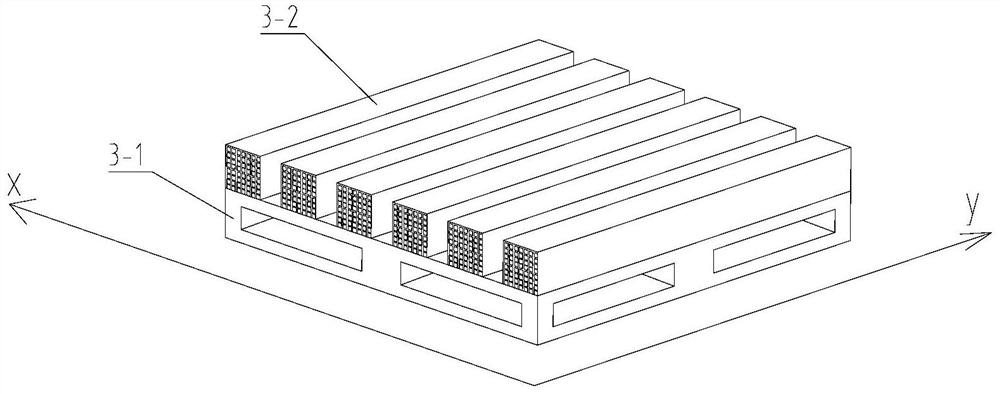

[0128] The invention provides a SCR denitrification catalyst robot equipment, which adopts the design scheme of guide rail robot + sponge suction cup fixture, has a wide coverage, many compatible products, and is compatible with the grasping and handling of catalyst products and paper trays at the same time, simple laser sensor + automatic deviation correction The method realizes automatic identification of materials, and is easy to operate and low in cost. The SCR denitration catalyst robot equipment of the present invention includes: a plurality of roasting kilns arranged evenly, upper kiln equipment and lower kiln equipment located on both sides of the roasting kiln; robot fixtures are fixed on the upper kiln equipment and the lower kiln equipment;

[0129] The upper kiln equipment is used to place the secondary dried SCR denitrification catalyst, and is also used to grab the placed catalyst to each roasting kiln with a robot gripper;

[0130] The lower kiln equipment is us...

Embodiment 2

[0145] Based on the same inventive concept, the present invention also provides an automatic deviation correction method for SCR denitrification catalyst robot equipment, including:

[0146] S1. When the catalyst needs to be put into the kiln: grab the secondary-dried SCR denitrification catalyst placed on the upper kiln equipment to each roasting kiln by using the robot fixture fixed on the upper kiln equipment;

[0147] S2 When the catalyst needs to be lowered into the kiln: use the robot fixture fixed on the lower kiln equipment to process the roasted catalyst on the roasting kiln in the lower kiln;

[0148]Among them, the upper kiln equipment, lower kiln equipment, roasting kiln and robot fixture are the upper kiln equipment, lower kiln equipment, roasting kiln and robot fixture described in a kind of SCR denitration catalyst robot equipment of the present invention.

[0149] Wherein in step S1, upper kiln workflow is as follows Figure 7 As shown, it specifically include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com