Thick aroma rapeseed oil cold smelting technological method

A process method, rapeseed oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of quality easily polluted by the environment, lack of strong fragrance, low safety, etc., and achieve the purpose of retaining nutrients , reduce the loss of nutrition, enhance the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

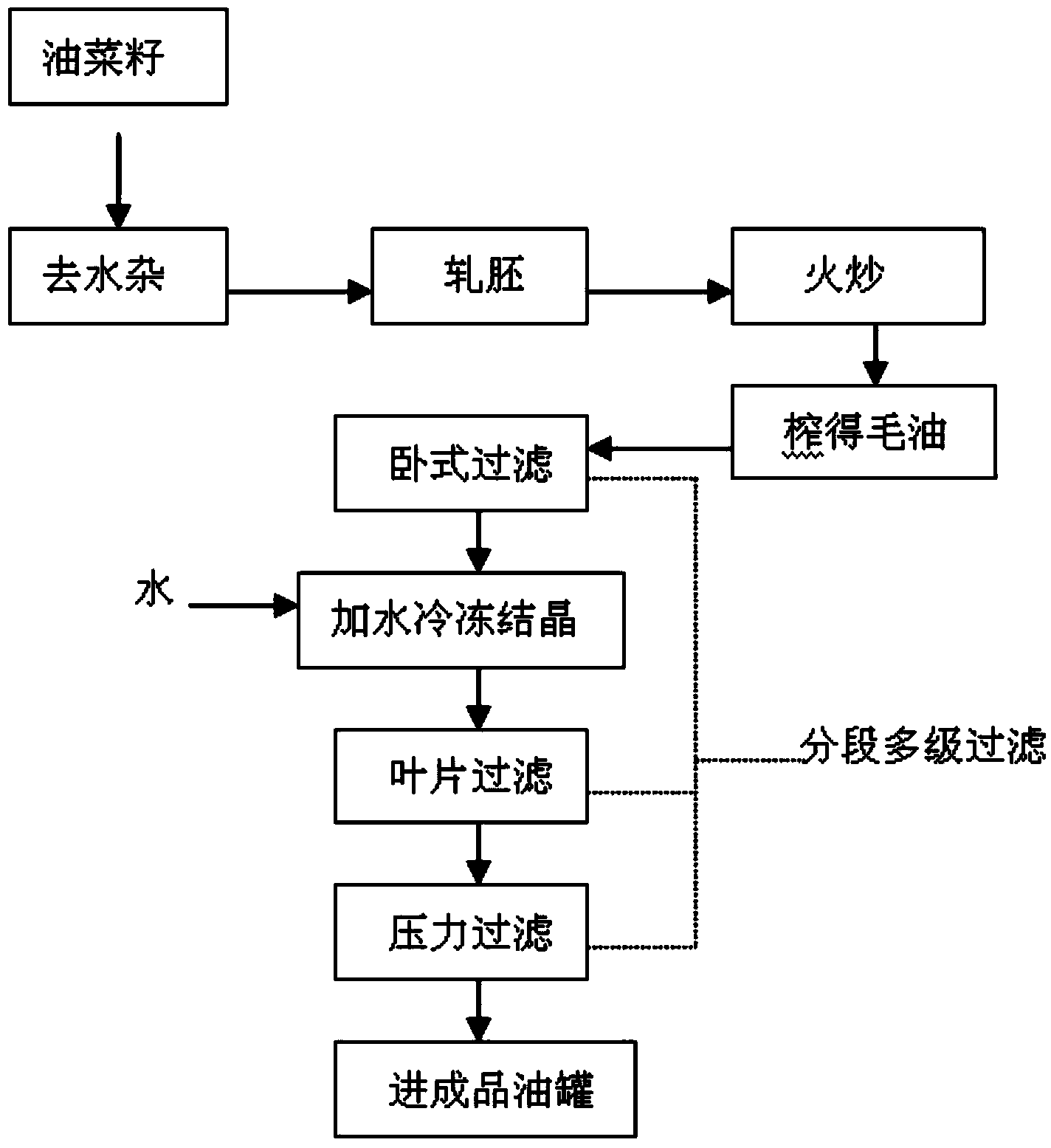

[0028] (1) Select the rapeseed produced in the current year, remove water and impurities;

[0029] (2) Flaking by flaking machine;

[0030] (3) Stir-fry the rapeseed with a drum frying machine equipped with an automatic temperature control and display system. The frying temperature is set at 250°C to fry the rapeseed;

[0031] (4) Squeeze to obtain the fragrant crude oil;

[0032] (5) Put the crude oil to settle in the clear oil tank to remove the crude oil impurities;

[0033] (6) Horizontal primary filtration is adopted;

[0034] (7) Put the primary filtered crude oil into a frozen crystallization tank, heat it to 60°C, add 60°C hot water accounting for 4% of the crude oil by weight, and freeze the crude oil through refrigeration equipment, combined with the crude oil content For the amount of phosphorus, set the freezing temperature to 5°C according to the conventional selection range, freeze, crystallize and grow crystals for 12 hours. After the inorganic impurities and...

Embodiment 2

[0039] (1) Select the rapeseed produced in the current year, remove water and impurities;

[0040](2) Flaking by flaking machine;

[0041] (3) Fire frying is carried out through a drum frying machine equipped with an automatic temperature control and display system, and the temperature of the drum frying machine is 320°C during fire frying;

[0042] (4) Squeeze to obtain fragrant crude oil

[0043] (5) Put the crude oil to settle in the clear oil tank to remove the crude oil impurities;

[0044] (6) Primary filtration

[0045] (7) Heat the crude oil to 65°C in the frozen crystallization tank, add 65°C hot water accounting for 5% by weight of the crude oil, and freeze the crude oil through a refrigeration device, set the freezing temperature to 5°C, crystallize, raise Crystallize for 12 hours, after the inorganic impurities and phospholipids in the water and oil form crystals, perform leaf filtration;

[0046] (8) Use plate and frame filter to carry out precise pressure fil...

Embodiment 3

[0050] (1) Select the rapeseed produced in the current year, remove water and impurities;

[0051] (2) Flaking by flaking machine;

[0052] (3) Fire frying is carried out through a drum frying machine equipped with an automatic temperature control and display system, and the temperature of the drum frying machine is 280°C during fire frying;

[0053] (4) Squeeze to obtain fragrant crude oil

[0054] (5) Put the crude oil to settle in the clear oil tank to remove the crude oil impurities;

[0055] (6) Primary filtration

[0056] (7) Heat the crude oil to 62°C in the frozen crystallization tank, add hot water at 62°C accounting for 5% of the crude oil by weight, and freeze the crude oil through refrigeration equipment, set the freezing temperature to 4°C, crystallize, grow Crystallize for 12 hours, after the inorganic impurities and phospholipids in the water and oil form crystals, perform leaf filtration;

[0057] (8) Use a plate and frame filter to perform pressure precisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com