Steel for large-capacity electronic gas cylinder and manufacturing method of steel

A technology of steel and electronic gas for gas cylinders, applied in the field of steelmaking in the metallurgical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

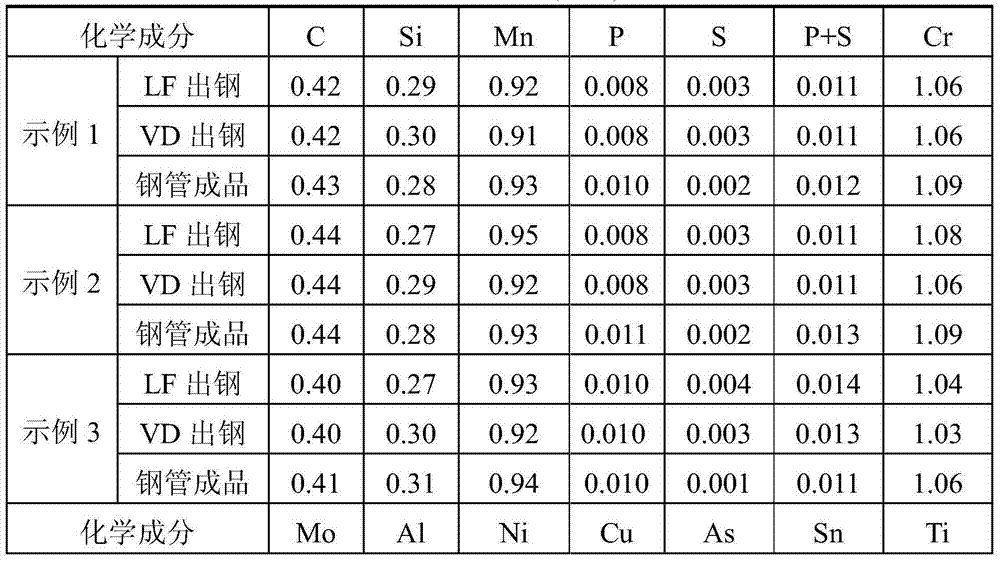

example 1

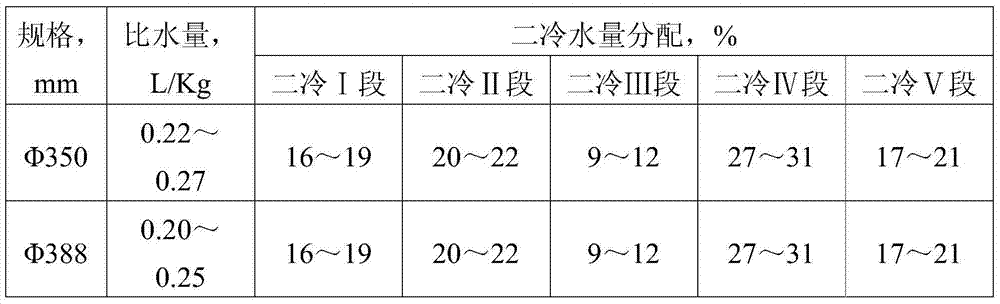

[0065] In the EBT-electric furnace with a nominal capacity of 70 tons, 30% molten iron and 70% steel scrap are added, and the foam slag submerged arc process is used in the smelting process to reduce the nitrogen in the air from being dissolved into the steel due to arc ionization. Eccentric bottom slag-free tapping (EBT) is adopted. The chemical composition of molten steel for electric furnace smelting is shown in Table 3, and As≤0.023% and Sn≤0.010% are controlled.

[0066] Tapping is carried out when the above tapping conditions are reached, and the tapping temperature is 1620°C. When the tapping amount is about 1 / 3, start to add deoxidizer CaBaAlSi2.0Kg / t steel, add Al block 1.5Kg / t steel and suitable ferromanganese alloy for alloying. After tapping and before entering LF, feed Al line 3m / t steel.

[0067] When the ladle enters the LF refining station, a submerged arc operation with a large amount of slag is adopted to reduce the contact between the molten steel and the ...

example 2

[0072] In the EBT-electric furnace with a nominal capacity of 70 tons, 45% molten iron and 55% steel scrap are added, and the foam slag submerged arc process is used in the smelting process, which can reduce the nitrogen in the air from being dissolved into the steel due to arc ionization. Eccentric bottom slag-free tapping (EBT) is adopted. The chemical composition of molten steel for electric furnace smelting is shown in Table 3, and As≤0.023% and Sn≤0.010% are controlled.

[0073] Tapping is carried out when the above tapping conditions are reached, and the tapping temperature is 1640°C. When the tapping amount is about 1 / 3, start to add deoxidizer CaBaAlSi3.5Kg / t steel, add Al block 1.2Kg / t steel and suitable ferromanganese alloy for alloying. After tapping and before entering LF, feed Al line 4m / t steel.

[0074] When the ladle enters the LF refining station, a submerged arc operation with a large amount of slag is adopted to reduce the contact between the molten steel ...

example 3

[0079] In the EBT-electric furnace with a nominal capacity of 70 tons, 35% molten iron and 65% steel scrap are added, and the foam slag submerged arc process is used in the smelting process, which can reduce the nitrogen in the air from dissolving into the steel due to arc ionization. Eccentric bottom slag-free tapping (EBT) is adopted. The chemical composition of molten steel for electric furnace smelting is shown in Table 3, and As≤0.023% and Sn≤0.010% are controlled.

[0080] Tapping is carried out when the above-mentioned tapping conditions are reached, and the tapping temperature is 1660° C. When the tapping amount is about 1 / 3, start to add deoxidizer CaBaAlSi2.5Kg / t steel, add Al1.3Kg / t steel and suitable ferromanganese alloy for alloying. After tapping and before entering LF, feed Al line 5m / t steel.

[0081] When the ladle enters the LF refining station, a submerged arc operation with a large amount of slag is adopted to reduce the contact between the molten steel a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com