Pressure difference control system of MOCVD (Metal Organic Chemical Vapor Deposition) gas circuit

A control system and gas circuit technology, applied in gaseous chemical plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

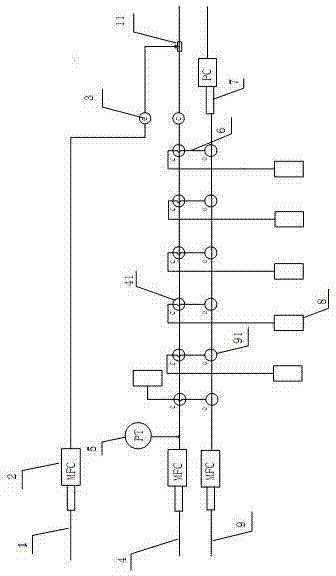

[0021] A MOCVD gas path pressure difference control system for growing gallium nitride (GaN), including: main carrier gas pipeline 1, main gas path pipeline 4 and bypass pipeline 9, main carrier gas pipeline 1 leads to H 2 or N 2 or H 2 , N 2 Mixed carrier gas, there are five kinds of organic sources for the reaction gas that can be introduced into the main gas pipeline 4: trimethylgallium (TMGa), triethylgallium (TEGa), trimethylaluminum (TMAl), trimethyl Indium (TMIn), p-type dopant magnesocene (CP 2 Mg) and n-type dopant silane: SiH 4 . The front ends of the main carrier gas pipeline 1, the main gas pipeline 4 and the bypass pipeline 9 are all equipped with a mass flow meter (MFC) 2, and the ends of the main gas carrier pipeline 1 and the main gas pipeline 4 are equipped with a normally closed valve 11, A pressure sensor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com