Electrolytic bath, acid etching liquid regenerating equipment and method using electrolytic bath

An acid etching solution and electrolytic cell technology, applied in the field of electrolytic cells, can solve the problems of poor etching solution effect and chemical mismatch of etching copper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

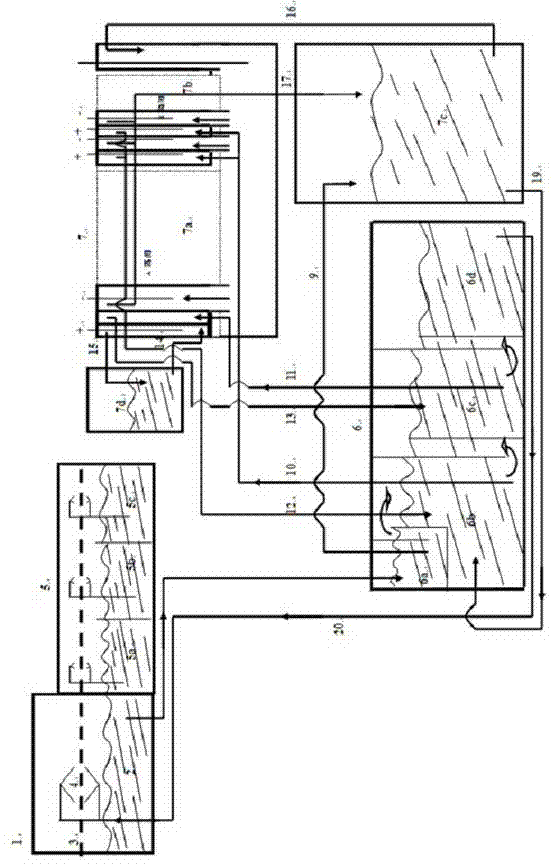

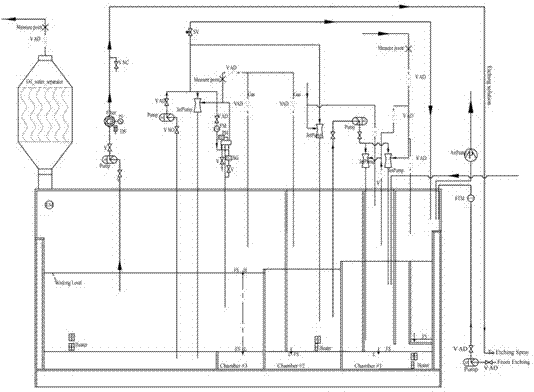

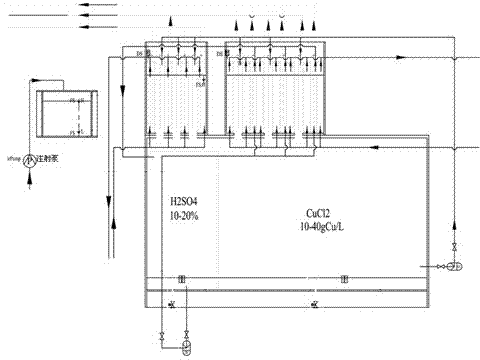

[0077] The invention discloses a device and method capable of regenerating acid etching solution and recovering copper.

[0078] Such as Figure 1 to Figure 5 As shown, the printed circuit board 3 is processed by the etching solution 2 sprayed by the nozzle 4 in the etching machine 1 . The rinse from the rinse module 5 is then received. After etching, the etching solution 2 becomes an acidic etching waste solution and is sent to the reactor 6. The waste solution may contain the following chemical substances: hydrochloric acid, cupric chloride, sodium chloride, sodium perchlorate and water. After treatment, the regenerated acidic etching solution 2 from the reactor 6 will be sent to the nozzle 4 of the etching machine 1 .

[0079] Specifically, the reactor 6 connected to the etching machine includes three overflow chambers and a pre-overflow chamber 6a, and the three overflow chambers are respectively the first overflow chamber 6b, the second overflow chamber 6c, and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com