Preparation method of filtering adsorption paper

A production method and technology of adsorption paper, which are applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of low mechanical performance, poor adsorption and filtration performance, etc., and achieve the effect of solving low mechanical performance and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preparation method of filter adsorption paper described in the embodiment of the present invention comprises the following steps:

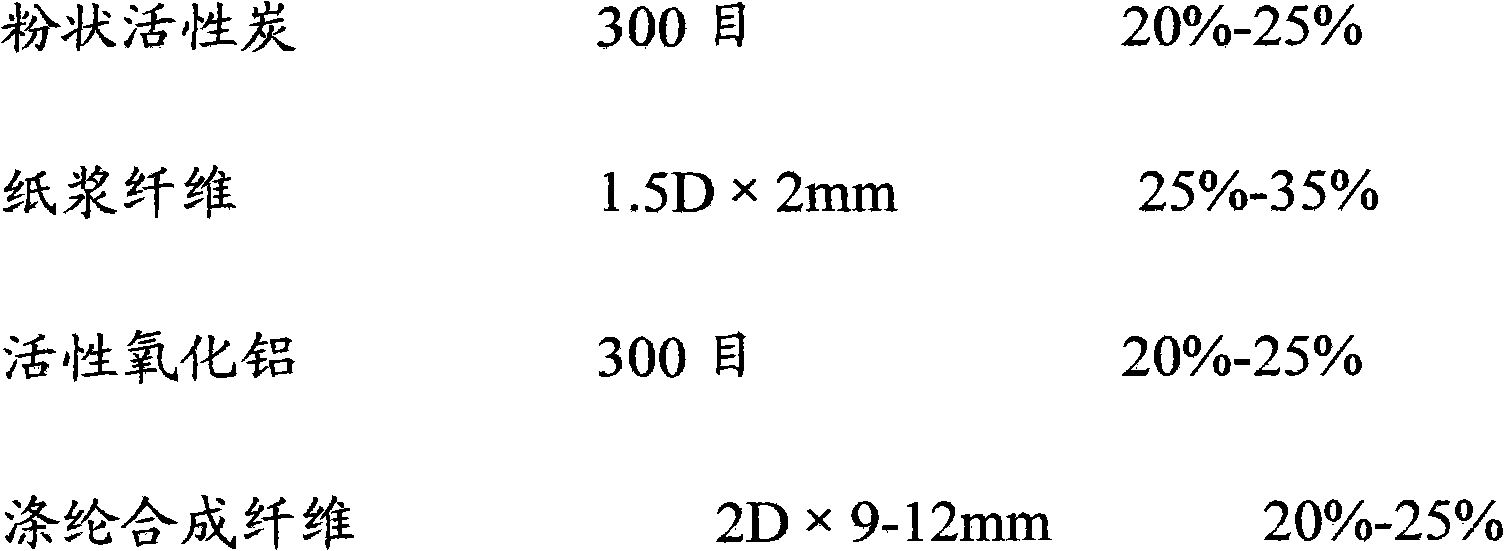

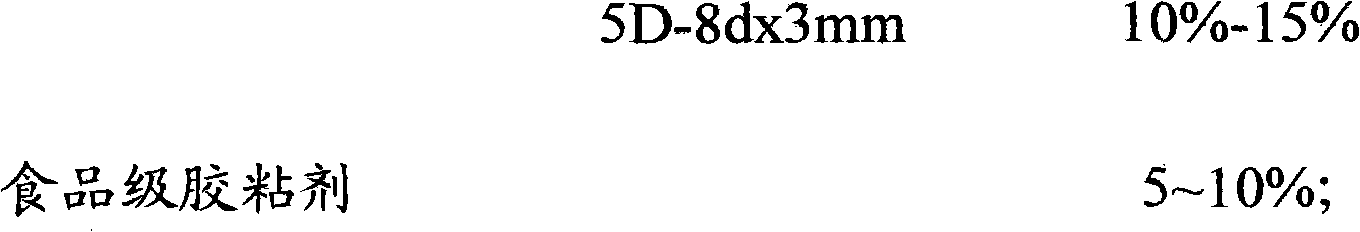

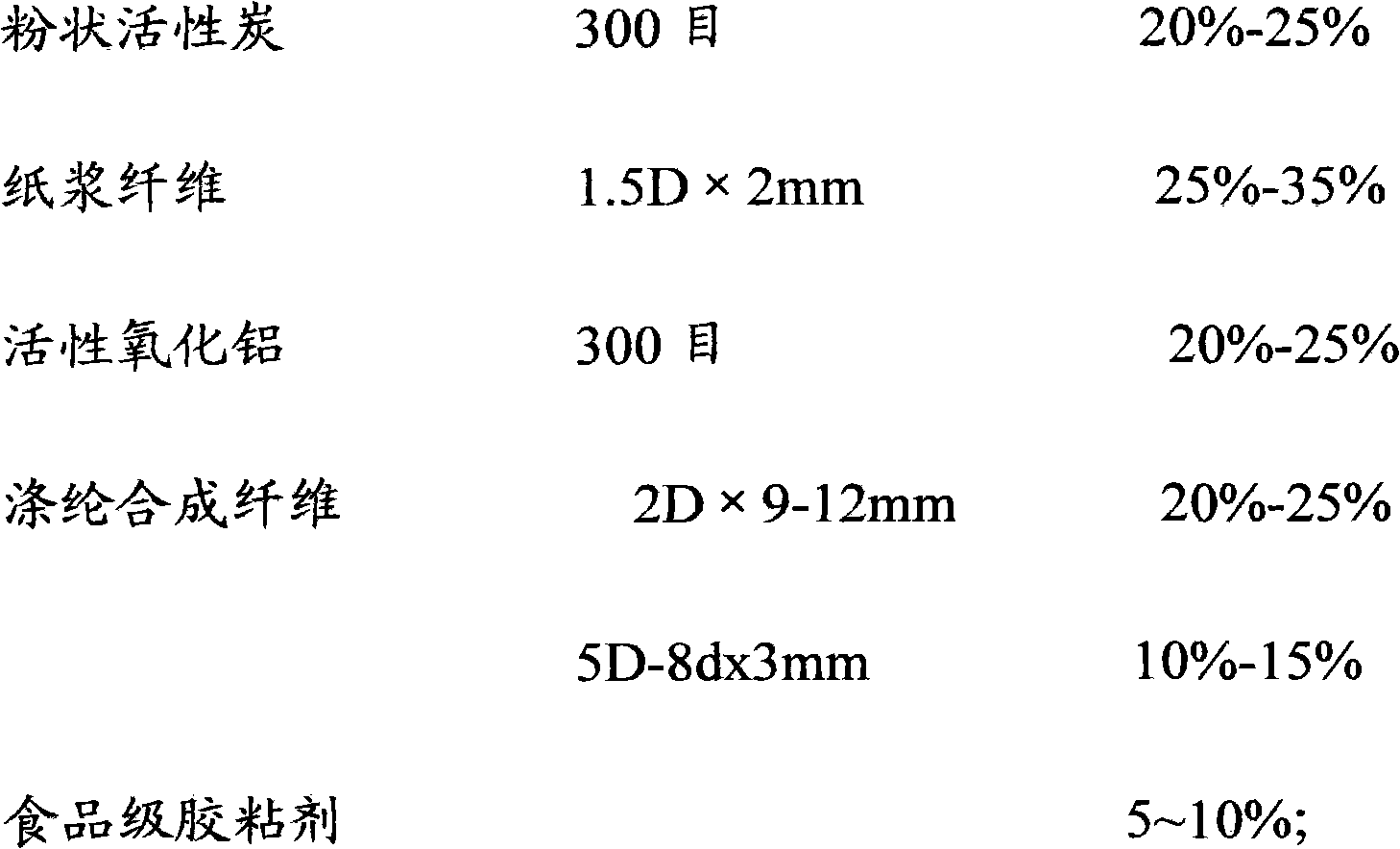

[0022] (1) Taking 200kg per cylinder as 100% of the total amount as a reference, the following raw material ratios are carried out:

[0023]

[0024] (2) Set up a production line in the fully enclosed workshop, mix the charcoal and fiber with 50kg of powdered activated carbon, add 50kg of water and stir evenly in the raw material pool for later use

[0025] (3) Put 50kg of pulp fiber and purified water equivalent to 5 times its own weight into a high-consistency hydraulic pulper for 20 minutes of uniform pulping;

[0026] (4) Put 300kg of water, 25kg of pulp fiber, and 50kg of synthetic fiber into the thermostat for stirring. When the thermostat reaches 40°C, stir continuously for 10 minutes and then input it into the high-consistency beating tank together with 50 kg of evenly stirred activated carbon, and add food to the beating tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com