Ammonia spraying and uniform-mixing device capable of automatically adjusting ammonia flow based on amount of flue gas

An automatic adjustment and adjustment device technology, applied in the direction of fluid mixers, mixers, mixer accessories, etc., can solve the problems that the amount of ammonia injection cannot be adjusted independently, and it is difficult to achieve local mixing uniformity, so as to improve the mixing uniformity of the flow field, The effect of reducing the mixing length and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

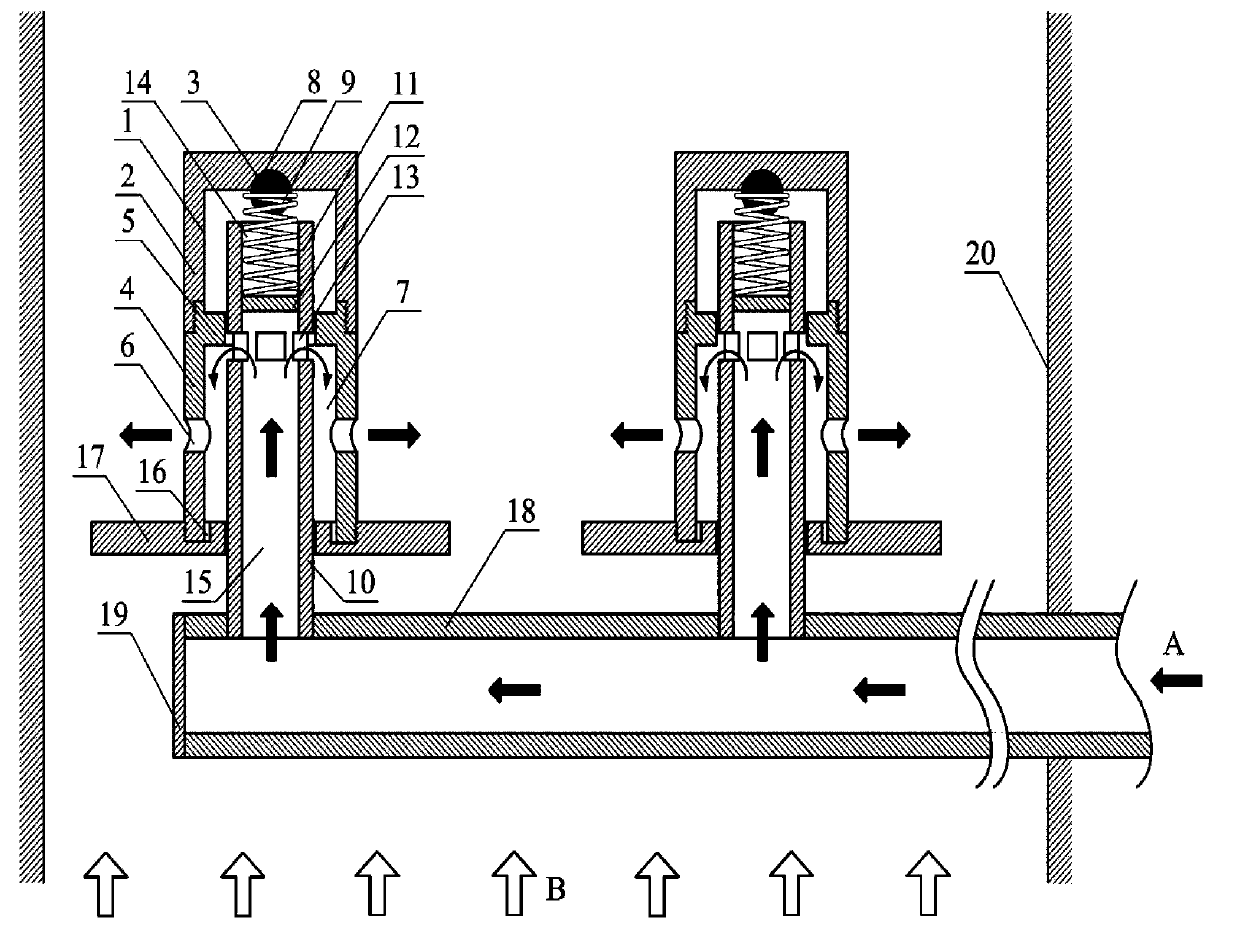

[0034] In this example, an ammonia injection device is designed for a cold model test bench designed at a ratio of 1:1 for the SCR denitrification system of a certain power plant, and a corresponding physical model and mathematical model are established. For comparison and illustration, three ammonia injection schemes were designed in the numerical experiment:

[0035] In the first scheme, three Φ20 ammonia injection holes are set on the Φ32 pipe at a distance of 80mm as the ammonia injection pipe;

[0036] The second scheme uses Φ20 pipe as the ammonia injection tube on the basis of the above, one end is inserted into the small hole of the ammonia injection tube and welded to it, the other end is closed, and three rectangular ammonia injection holes are opened on the side, the hole height is 5mm;

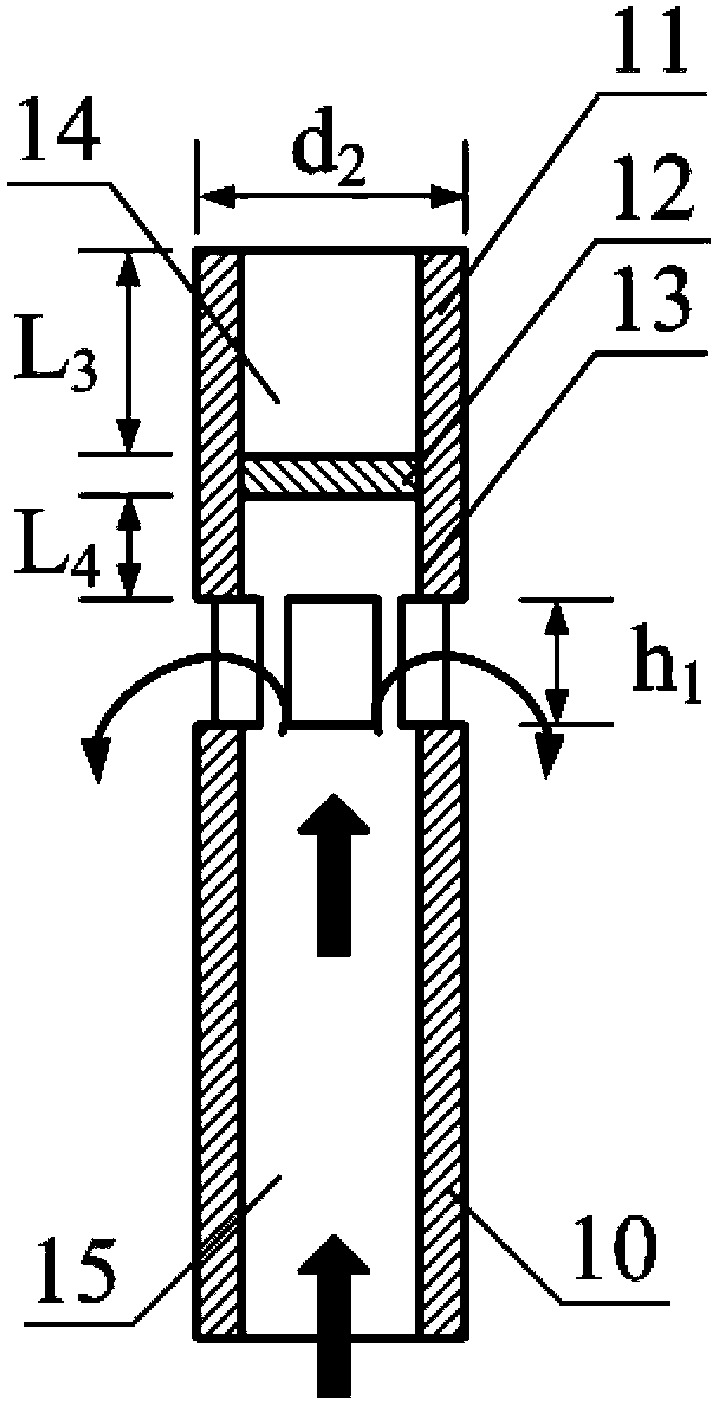

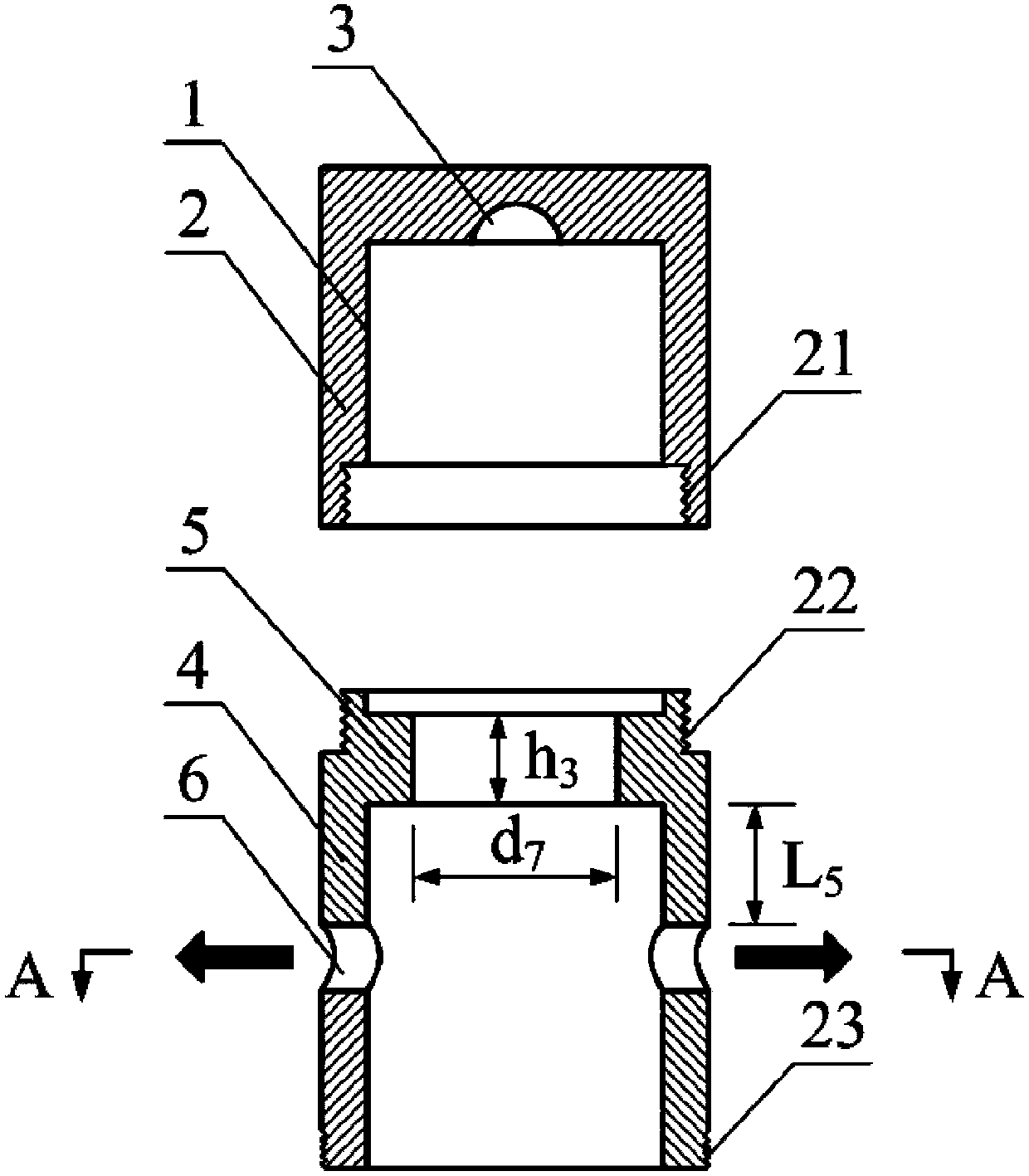

[0037] The third scheme is the content of the present invention, using Φ32 pipes as the ammonia spraying main pipe, opening 3 Φ20 small holes at intervals of 80 mm on the pipe, usi...

Embodiment 2

[0042] In this embodiment, an ammonia injection device is designed for the SCR denitrification system of a certain power plant. The Φ76 pipe is used as the ammonia injection main pipe, and 5 small holes of Φ32 are opened on the pipe at intervals of 200mm. The Φ32×2 pipe is used as the ammonia injection pipe, one end is inserted into the small hole of the main pipe and welded to it, the other end is divided into a positioning groove and an ammonia sink cavity at a distance of 20mm from the port, and 3 holes are set around the pipe 20mm away from the partition A rectangular ammonia injection hole with a height of 10mm. Put the spring with an outer diameter of 28mm and a height of 35mm into the positioning groove, and place a steel ball with a diameter of 28mm on the top of the spring. A circular plate of Φ120 is used as the swirl plate, and it is connected with the assembled swirl nozzle and set on the ammonia injection sub-pipe. There is a 12mm thick annular boss inside the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com